Sweep-off type depalletising

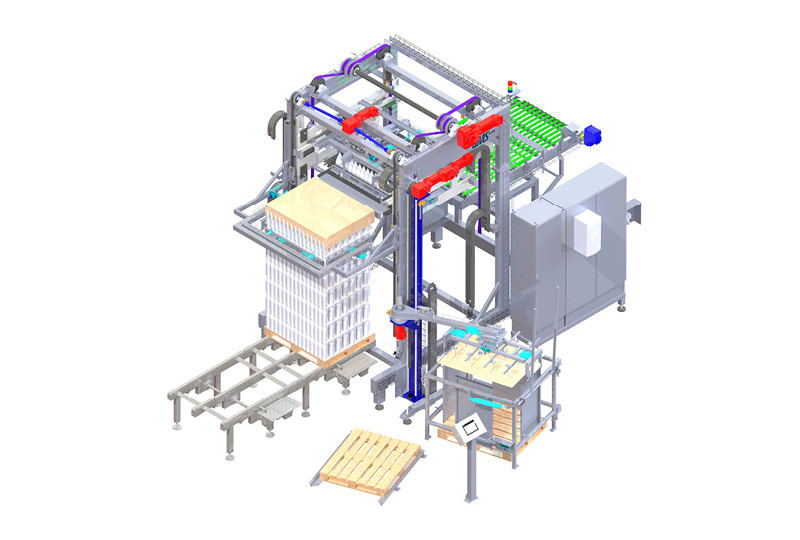

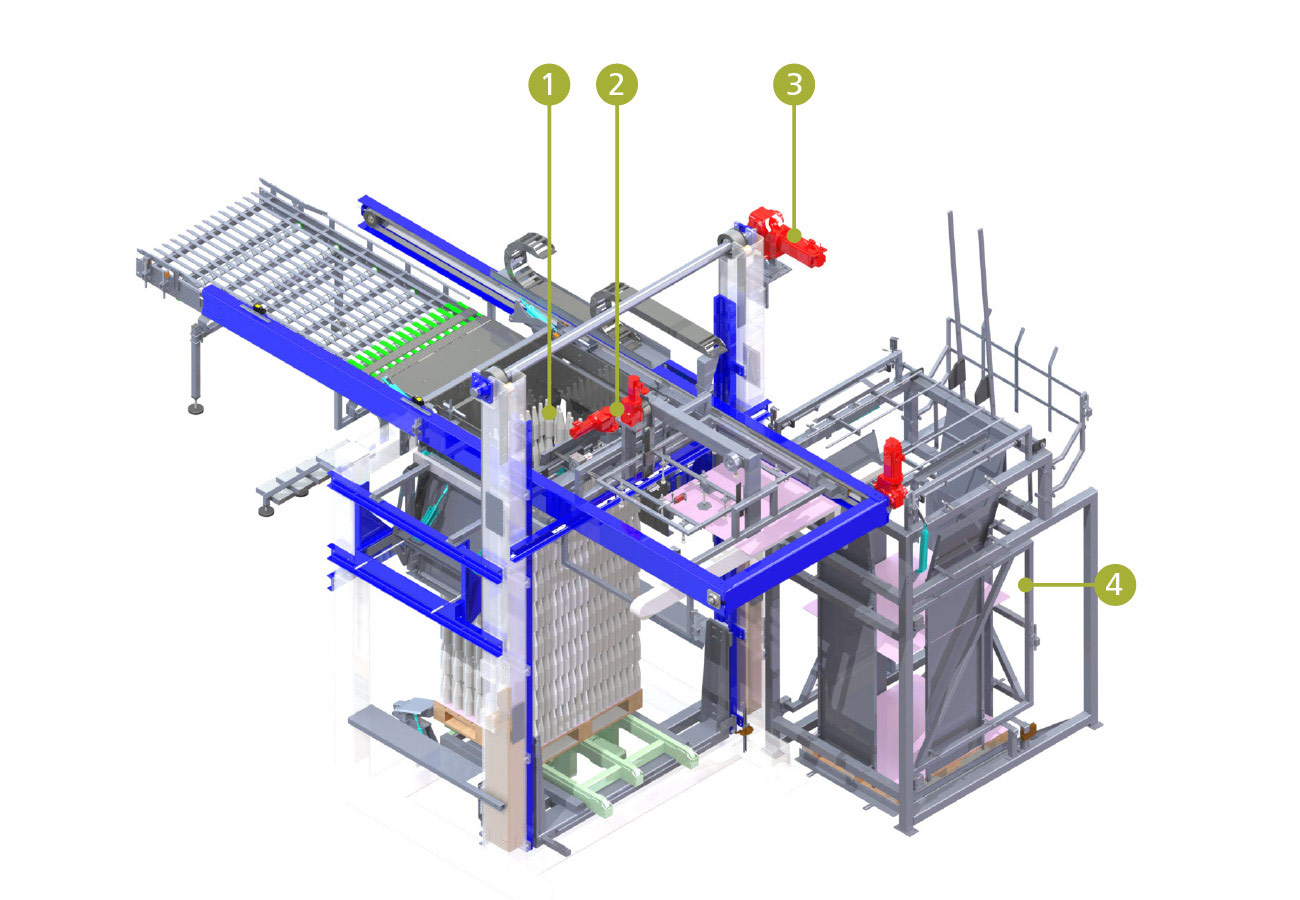

BMS new glass sweep-off depalletiser UNIPAL 202 – the ideal machine for the infeed of new glass and/or cans into your filling plant.

With the new-developed UNIPAL 202 new glass sweep-off depalletiser BMS delivers both diversity and high output levels in the small and medium performance range. In addition, the new glass sweep-off depalletiser UNIPAL 202 offers all the advantages of the BMS portal design, such as maximum flexibility, small footprint and modular design for easy integration into your existing plant system.

The sweep-off axis in telescopic design permits overlapping axis movements and therefore faster cycle times with minimum space requirement. In this way, up to 200 layers can be processed per hour in the smallest of spaces. The telescopic design of the sweep-off axis also permits discharge of the containers at any height and simultaneously reduces the risk of collision with other machines.

The BMS new glass sweep-off depalletiser UNIPAL 202 is extendible with external modules such as, for instance, an external centring system. Continuous holding of the top layer of the new glass pallet beyond the sweep-off process guarantees maximum process reliability.

It is also possible to supplement the BMS new glass sweep-off depalletiser UNIPAL 202 with an additional external module – a layer pad remover. Inverted trays, top frames, layer pads and bottom layers as well as empty pallets are taken up by the layer pad remover, stacked or placed in a magazine. Perhaps you need a third storage bay? We have a solution for this as well: by simply supplementing the new glass sweep-off depalletiser with a second layer pad remover.

With the BMS new glass sweep-off depalletiser UNIPAL 202 you can handle all standard pallet sizes and containers. The quiet and reliable operation of the machine as well as its simple operating concept establish a very high level of plant availability. In short, the new-developed new glass sweep-off depalletiser UNIPAL 202 sets new standards in footprint, availability, flexibility and performance.

Many years of experience in the palletising sector, along with our highly trained and innovative engineers, ensure you the best mechanical engineering, functionality and performance in this application as well.

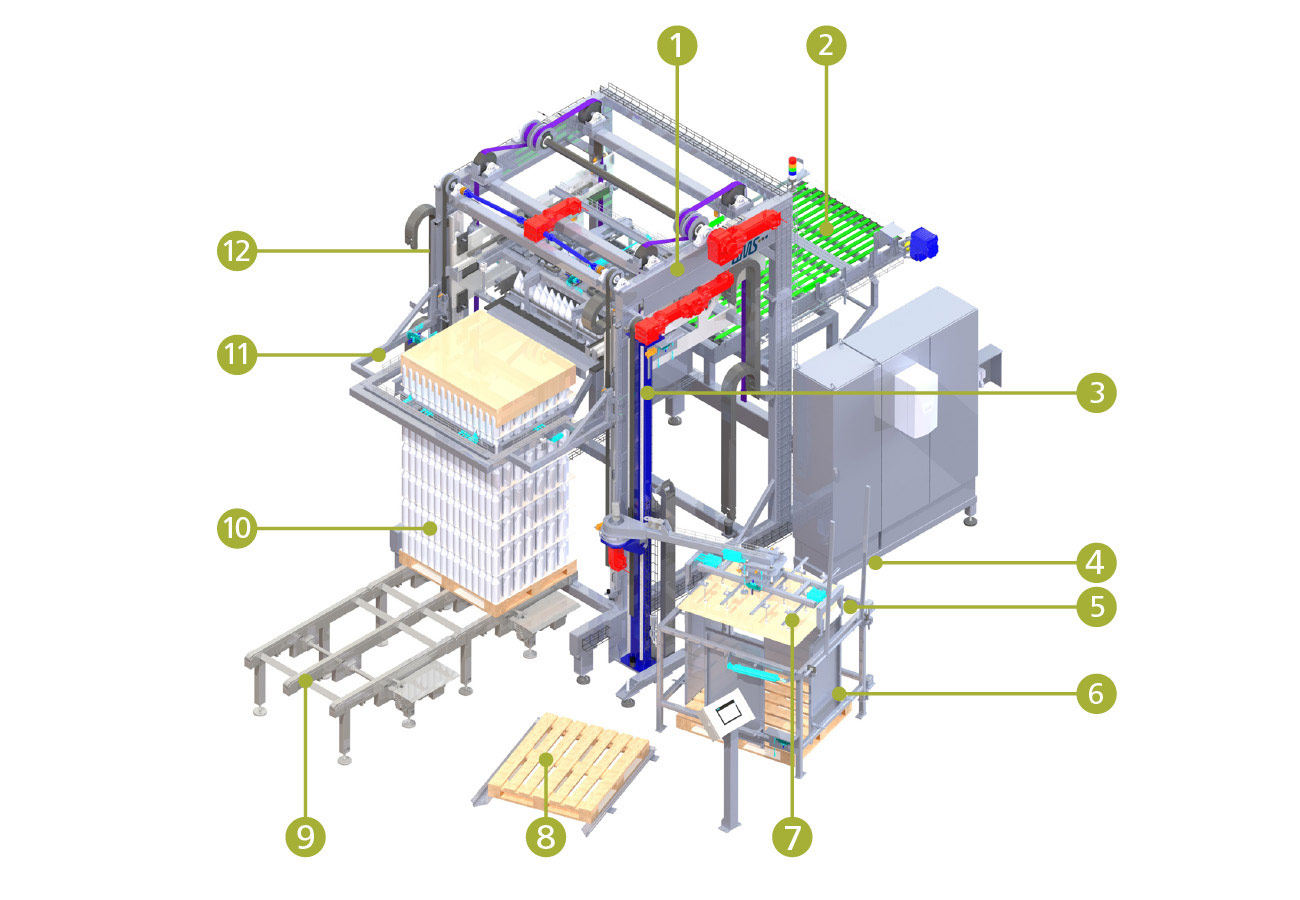

- Stainless steel base frame

- Bottle table

- Lift column for layer pad remover

- Inverted tray separator

- Pallet gripper

- Layer pad magazine

- Layer pad suction device

- Position for pallet stack

- Pallet conveyor

- Pallet sizes: glassworks and Euro

- Centring frame

- Lift carriage with telescope

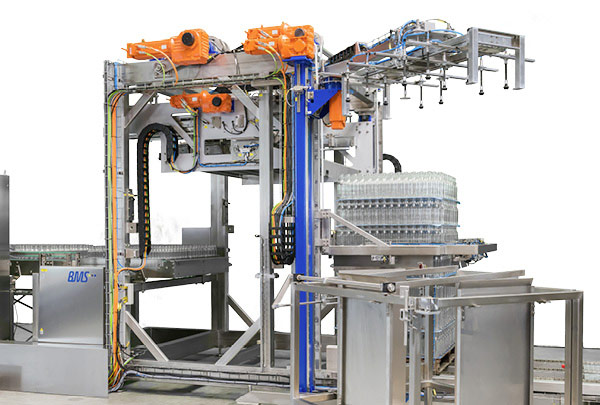

BMS new glass sweep-off depalletiser in operation

UNIPAL 202 – New glass sweep-off depalletiser for the small and medium performance range

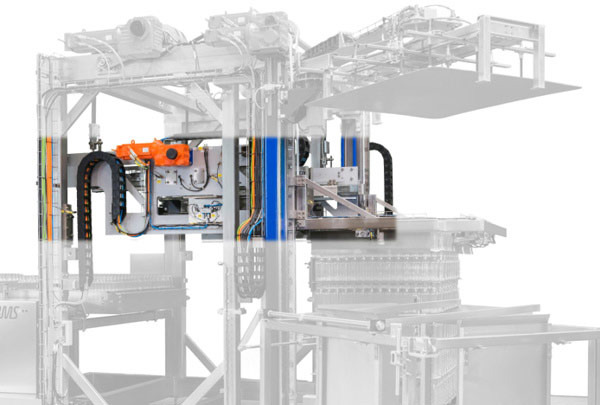

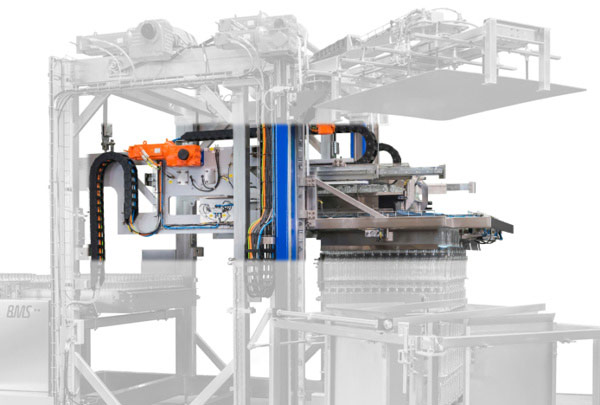

UNIPAL 202 – Lift carriage with retracting telescope

UNIPAL 202 – Lift carriage with extending telescope

UNIPAL 202 – Layer pad suction device

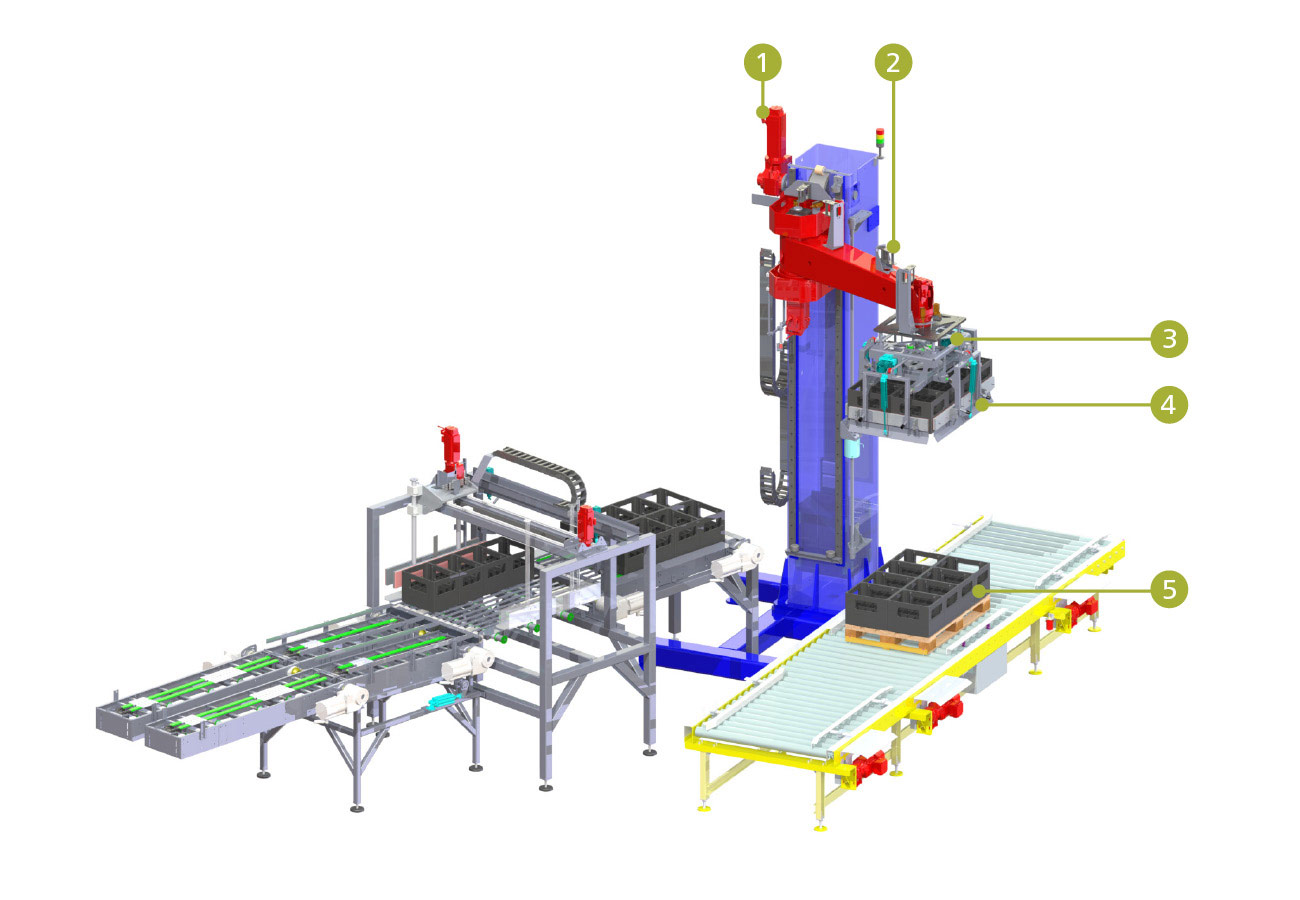

BMS portal machine UNIPACK 2.0 – overview of technologies

Product advantages UNIPAL

- Robust and durable machine design

- Designed for high outputs*

- Modular system for flexible project planning

- Machine concept with enhanced energy efficiency through state-of-the-art servo drives and counterweights

- Proven Siemens PLC and SEW drive technology

- Individual and customer-specific machine size

- Modular design as linear-arm or swivel-arm robot

- Sweep-out version with top discharge or height adjustment

* The output of the machine depends on the type of container and the used packing aids

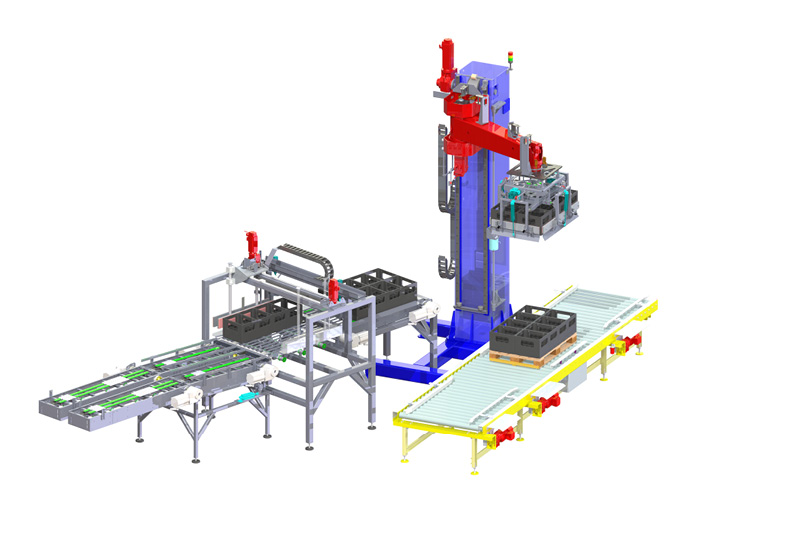

The BMS UNIPAL series

Column-type technology

BMS palletiser UNIPAL 107/108

The column-type robots BMS UNIPAL 107/108 can be used in multiple ways for the palletising and depalletising of e.g. beverage crates, shrink-packs, multipacks or cartons. The column robots reach maximum speeds of 450 cycles/h and handle loads of up to 750 kg. They are available as swivel-arm or linear-arm robots. Due to their motion control system and specific application of counterweights these BMS column-type robots are extremely accurate and energy efficient. The product-optimised gripper systems also ensure optimal pack protection and high stacking quality. The column-type robots BMS UNIPAL 107/108 can be additionally fitted with quick-changeover equipment for the gripper system as well as with customised lifting and swivel or linear motions as optional extensions.

- Motion Control Siemens PLC und SEW drive technology

- Highly dynamic servo-technology and precision positioning

- Designed for high loads of up to 750 kg

- Perfectly adapted gripper heads with optional quick-release coupling

- Flexible application for handling crates, cartons, shrink-packs and multipacks

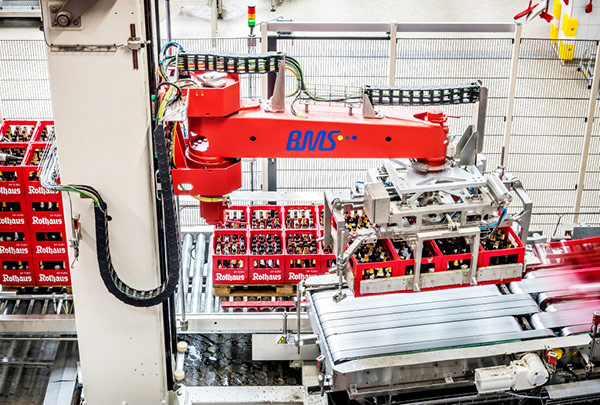

BMS Column-type palletiser – the UNIPAL 107/108 in operation

UNIPAL 108 – Depalletising plant

UNIPAL 108 – Palletising plant

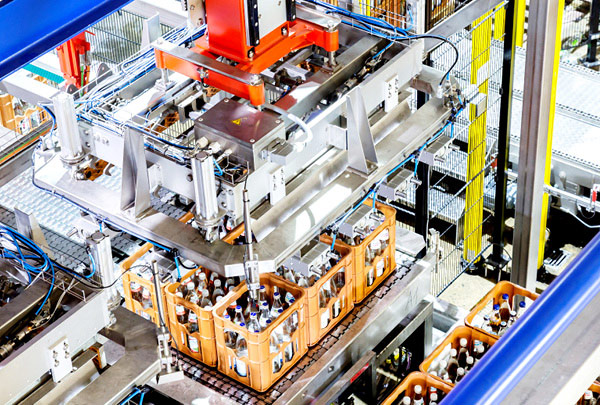

UNIPAL 108 – Layer gripper head

UNIPAL 108 – Hook gripper head

UNIPAL 107/108 - overview of technologies:

Product advantages of the UNIPAL

- Robust and durable machine design

- Designed for high loads

- Modular concept for flexible project planning

- Power-optimised machine design through state-of-the-art servo drives and the use of counterweights

- Proven Siemens PLC and SEW drive technology

- Individual and customer-specific machine size

- Modular design as linear-arm or swivel-arm robot

- Available as depalletiser, palletiser, combined palletiser or picking palletiser

Axis systems

Lifting carriage (Z)

- Stroke range 2,300mm (in standard version)

- Integrated counterweight

- Maintenance-free toothed belt system, no high-maintenance chain drives

- SEW servo drive technology

- INA linear guide for highest requirements

Swivel arm (W)

- Working radius 1,500mm

- Swivel range 210°

- SEW Servo drive technology

- Clearance-free Cyclo precision gearbox

Orientation axis (J)

- Orientation range 210°

- SEW Servo drive technology

- Clearance-free Cyclo precision gearbox

Linear axis * (X)

- Longitudinal travel 1,600mm (in standard version)

- Maintenance-free toothed belt system, no high-maintenance rack and pinion drive

- SEW servo drive technology

- INA linear guide for highest requirements

* only UNIPAL 107

Gripper heads

- Hook gripper head

- Clamping gripper head

- Roller gripper head

- Combination gripper head

- Special and individual gripper heads

System extension

- Handling of intermediate pads

- Layer preparation

- Grouping stations

- Individual modules

- Layer pusher

The BMS UNIPAL series

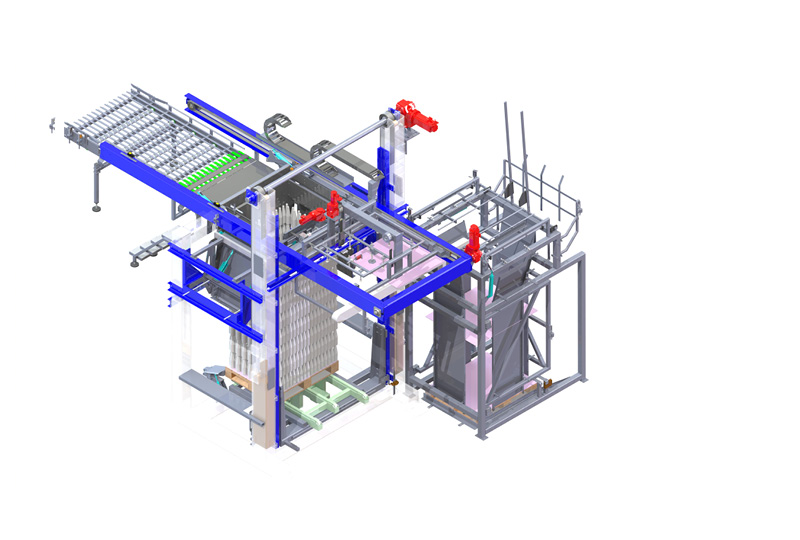

Sweep-off type depalletising

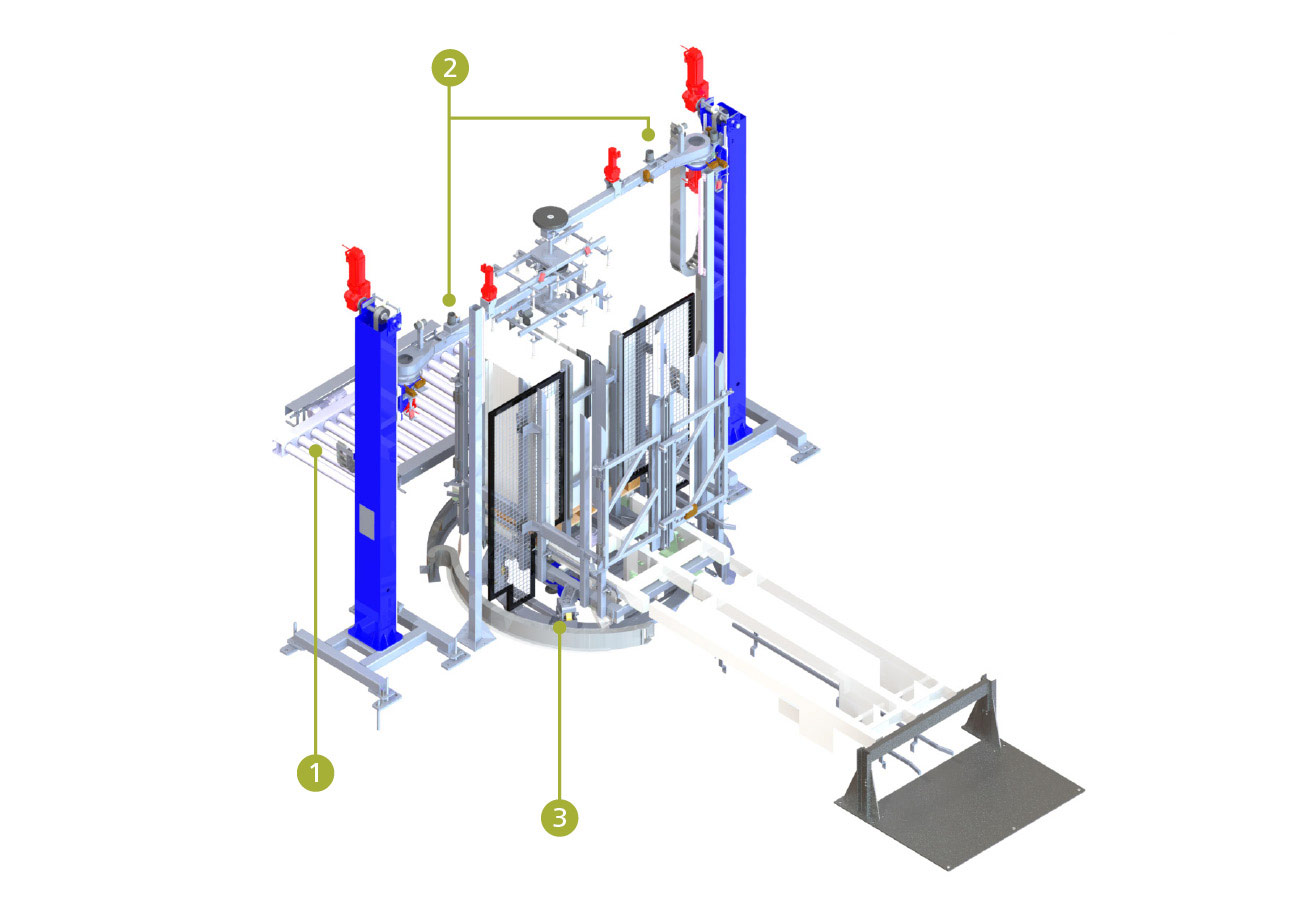

BMS new glass sweep-off depalletiser: UNIPAL 201

The BMS sweep-off depalletiser UNIPAL 201 with pallet lift and the UNIPAL 202 with height adjustment are top of the range machines that complete our programme of container handling equipment based on the proven UNIPAL technology. BMS sweep-off depalletisers process all types of containers used in the beverage industry and in all relevant performance ranges. Based on our many years of experience in palletising technology and with our qualified and innovative engineering staff we are able to offer the highest level of mechanical engineering, functionality and performance also in this application field.

The sweep-off depalletisers BMS UNIPAL 201/202 are high performance machines for depalletising new containers such as cans, jars or plastic containers. The integrated control and drive systems permit accurate positioning in a dynamic mode of operation. Due to the control concept and the specific use of counterweights the BMS sweep-off depalletisers are particularly energy efficient. The product-optimised gripper systems also ensure optimised and gentle handling of the pack.

- Layer centring using servo-controlled racks

- Motion Control Siemens PLC und SEW drive technology

- Highly dynamic servo technology and precision positioning with optimised energy consumption through state-of-the-art servo-drives and the use of counterweights

- Layer pad magazine

Layer pad handling

- Pallet bay for full goods

- Layer pad inserter with vacuum suction

- Rotating magazine, can swivel through 180°

UNIPAL 201 – overview of technologies

Product advantages UNIPAL

- Robust and durable machine design

- Designed for high outputs*

- Modular system for flexible project planning

- Machine concept with enhanced energy efficiency through state-of-the-art servo drives and counterweights

- Proven Siemens PLC and SEW drive technology

- Individual and customer-specific machine size

- Modular design as linear-arm or swivel-arm robot

- Sweep-out version with top discharge or height adjustment

* The output of the machine depends on the type of container and the used packing aids

The BMS UNIPAL series

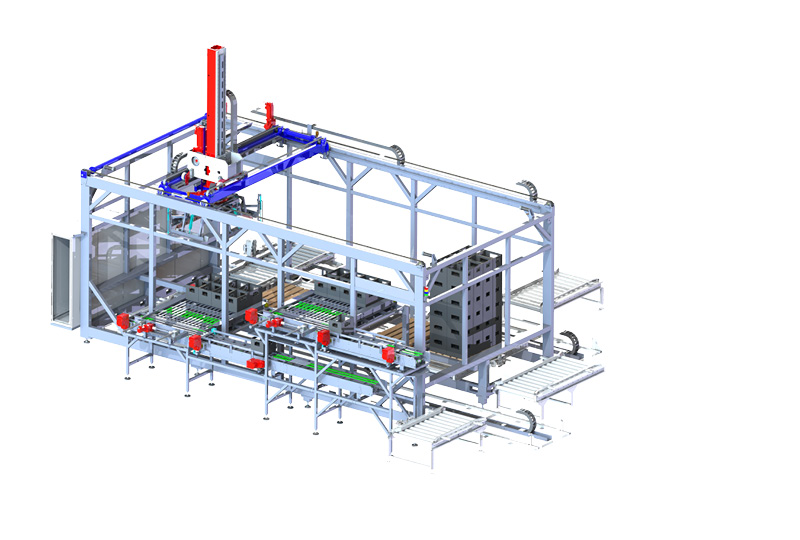

Portal technology

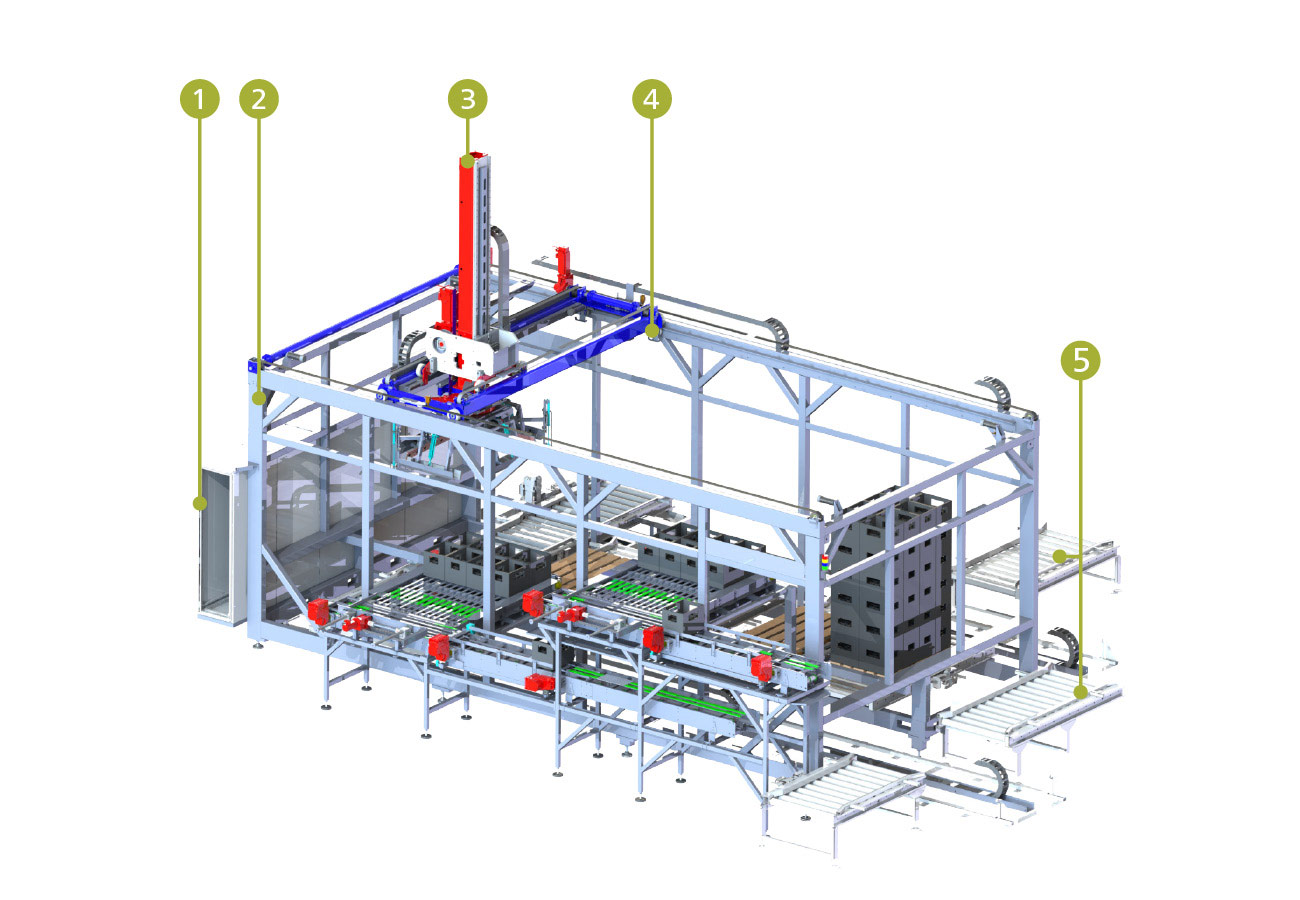

BMS palletiser UNIPAL 105/106

Characteristic feature of the portal-type palletiser BMS UNIPAL 105/106 is its accurate positioning even in the most powerful performance range. With its distortion-free welded stainless steel structure and unique bridge-type design of the X-axis - ensuring optimal load distribution - these machines are also extremely rugged and durable. Together with the maintenance-free drive technology the motion control system ensures gentle action on the product and material in an individually adjustable, rectangular work area with no dead areas or restrictions. With their modular design the portal-type palletisers permit highly flexible project planning. The arrangement of the infeed and discharge positions can also be freely selected. Depending on the machine version the portal-type palletisers BMS UNIPAL 105/106 are suitable for bottling plants with a capacity of up to 60,000 bottles/hour.

- Integrated control cabinet

- Base frame of a welded, stable, distortion-free stainless steel design

- Motion Control Siemens PLC und SEW drive technology

- Optimal load distribution through unique bridge-type design

- Flexible arrangement of infeed and discharge

UNIPAL 106

Palletising plant – processing of different pallet sizes

BMS portal-type palletiser: the UNIPAL 105/106 in operation

UNIPAL 105 – depalletising with clamping gripper head

UNIPAL 106 – depalletising and palletising plant with clamping gripper head and re-centring

UNIPAL 106 – depalletising and palletising plant

UNIPAL 106 – palletising plant for different pallet sizes

UNIPAL 105/106 - overview of technologies

Product advantages of UNIPAL

- Rugged and durable machine design

- Portal design in stainless steel profiles

- Modular concept that enables flexible project planning

- Individual, customer-specific portal size

- Safety technology integrated in the frame

- Proven Siemens PLC and SEW drive technology

- Available as depalletiser, palletiser, combined palletiser, picking palletiser

Axis systems

Portal axis (X-Y axis)

- Roller carriage design

- Maintenance-free toothed belt system, no high-maintenance rack and pinion drives

- SEW drive technology

- Portal size adjustable to suit customer’s needs

Lifting axis (Z axis)

- Designed as lifting column or telescopic design (optional)

- SEW drive technology

- Orientation axis (optional)

- Lift from 600 mm to 2400 mm

Gripper heads

- Hook gripper head

- Clamping gripper head

- Roller gripper head

- Combined gripper head

- Special and individually designed gripper heads

System extension

- Handling of intermediate pads

- Layer preparation

- Grouping stations

- Individual modules

- Layer pusher