Portal technology

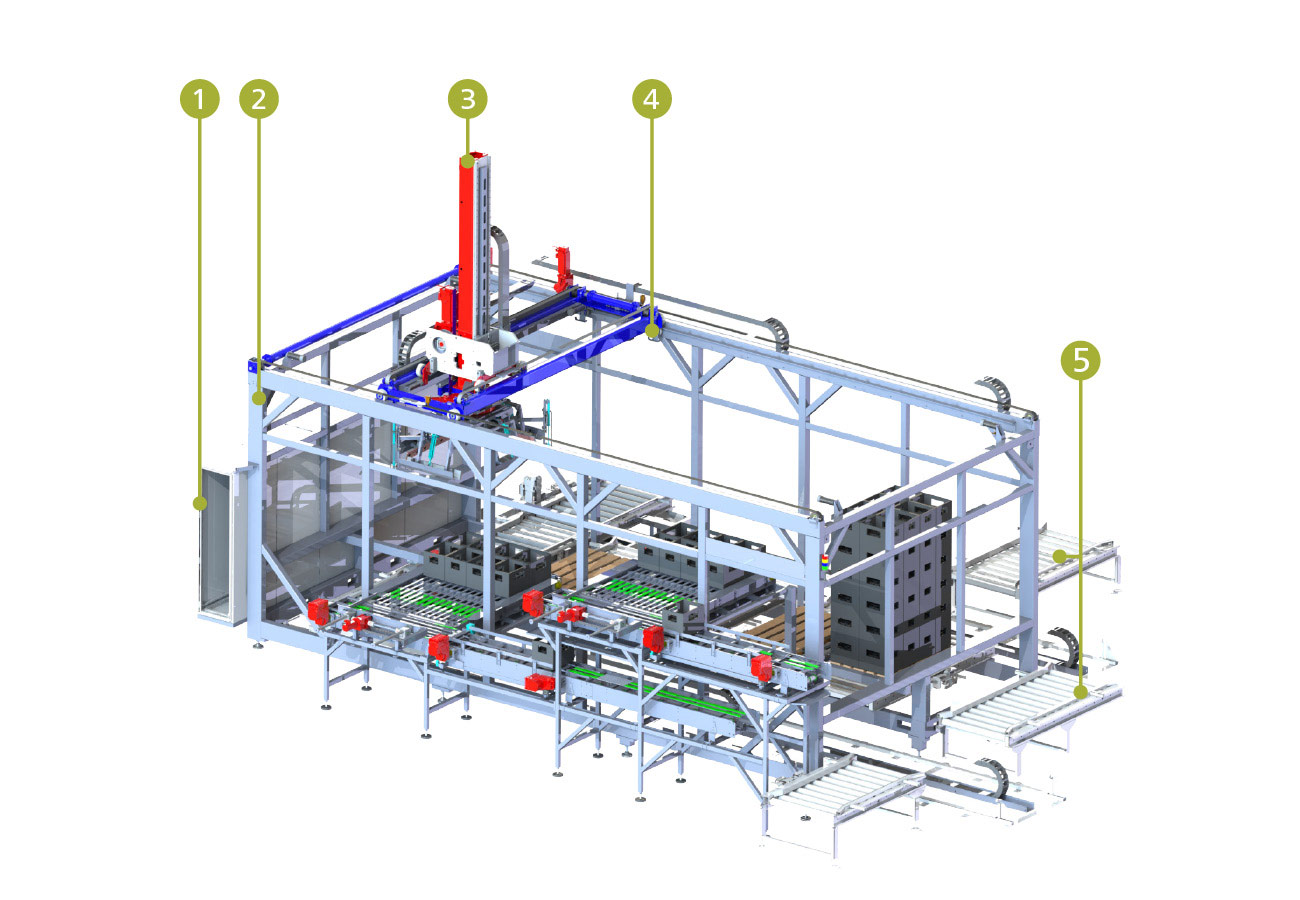

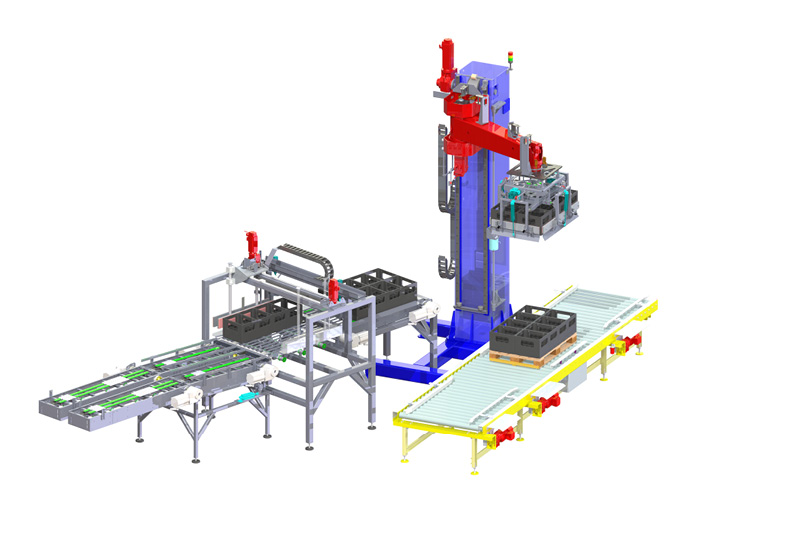

BMS palletiser UNIPAL 105/106

Characteristic feature of the portal-type palletiser BMS UNIPAL 105/106 is its accurate positioning even in the most powerful performance range. With its distortion-free welded stainless steel structure and unique bridge-type design of the X-axis - ensuring optimal load distribution - these machines are also extremely rugged and durable. Together with the maintenance-free drive technology the motion control system ensures gentle action on the product and material in an individually adjustable, rectangular work area with no dead areas or restrictions. With their modular design the portal-type palletisers permit highly flexible project planning. The arrangement of the infeed and discharge positions can also be freely selected. Depending on the machine version the portal-type palletisers BMS UNIPAL 105/106 are suitable for bottling plants with a capacity of up to 60,000 bottles/hour.

- Integrated control cabinet

- Base frame of a welded, stable, distortion-free stainless steel design

- Motion Control Siemens PLC und SEW drive technology

- Optimal load distribution through unique bridge-type design

- Flexible arrangement of infeed and discharge

UNIPAL 106

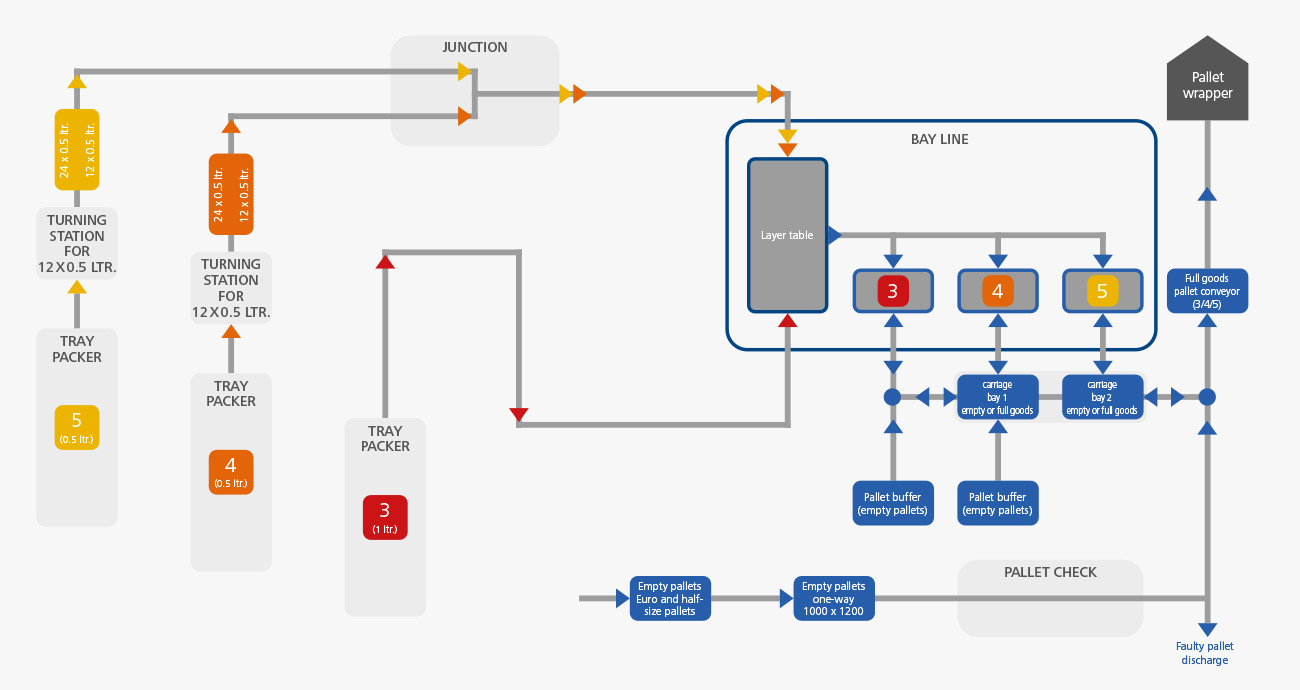

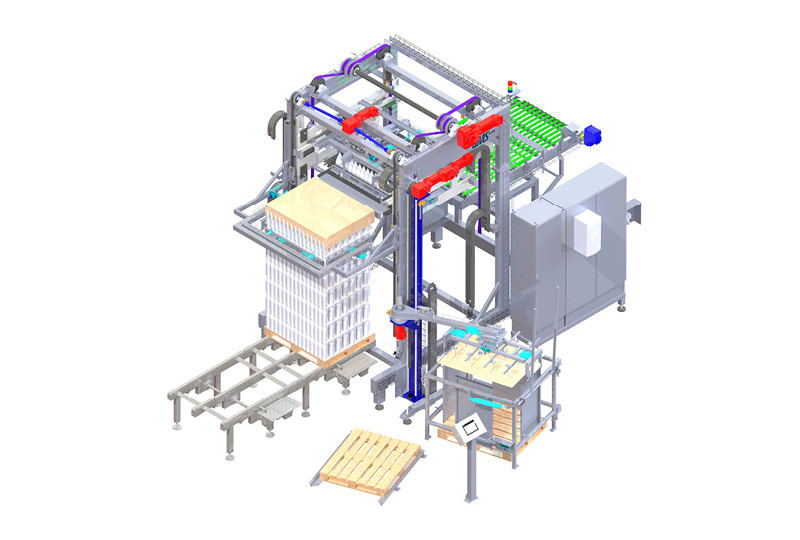

Palletising plant – processing of different pallet sizes

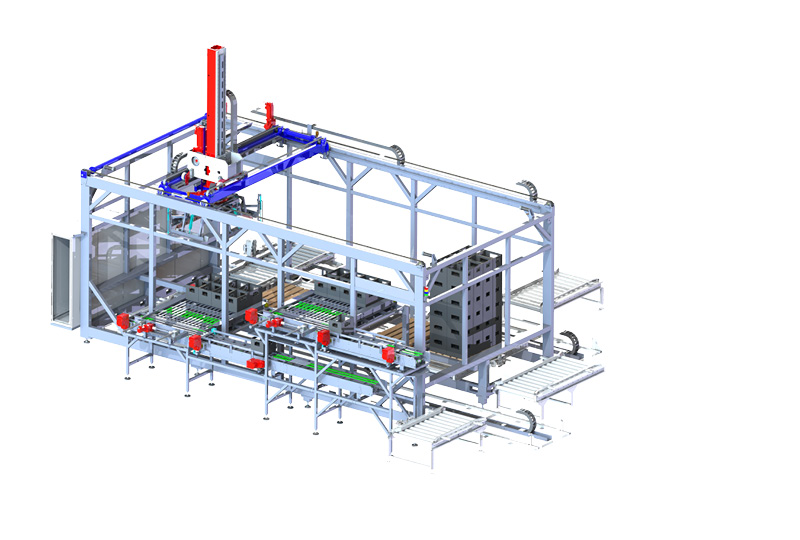

BMS portal-type palletiser: the UNIPAL 105/106 in operation

UNIPAL 105 – depalletising with clamping gripper head

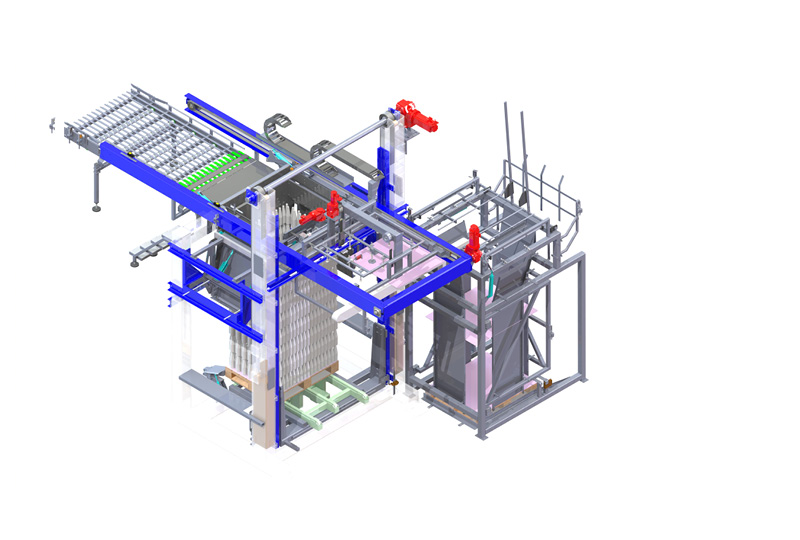

UNIPAL 106 – depalletising and palletising plant with clamping gripper head and re-centring

UNIPAL 106 – depalletising and palletising plant

UNIPAL 106 – palletising plant for different pallet sizes

UNIPAL 105/106 - overview of technologies

Product advantages of UNIPAL

- Rugged and durable machine design

- Portal design in stainless steel profiles

- Modular concept that enables flexible project planning

- Individual, customer-specific portal size

- Safety technology integrated in the frame

- Proven Siemens PLC and SEW drive technology

- Available as depalletiser, palletiser, combined palletiser, picking palletiser

Axis systems

Portal axis (X-Y axis)

- Roller carriage design

- Maintenance-free toothed belt system, no high-maintenance rack and pinion drives

- SEW drive technology

- Portal size adjustable to suit customer’s needs

Lifting axis (Z axis)

- Designed as lifting column or telescopic design (optional)

- SEW drive technology

- Orientation axis (optional)

- Lift from 600 mm to 2400 mm

Gripper heads

- Hook gripper head

- Clamping gripper head

- Roller gripper head

- Combined gripper head

- Special and individually designed gripper heads

System extension

- Handling of intermediate pads

- Layer preparation

- Grouping stations

- Individual modules

- Layer pusher

Select your language