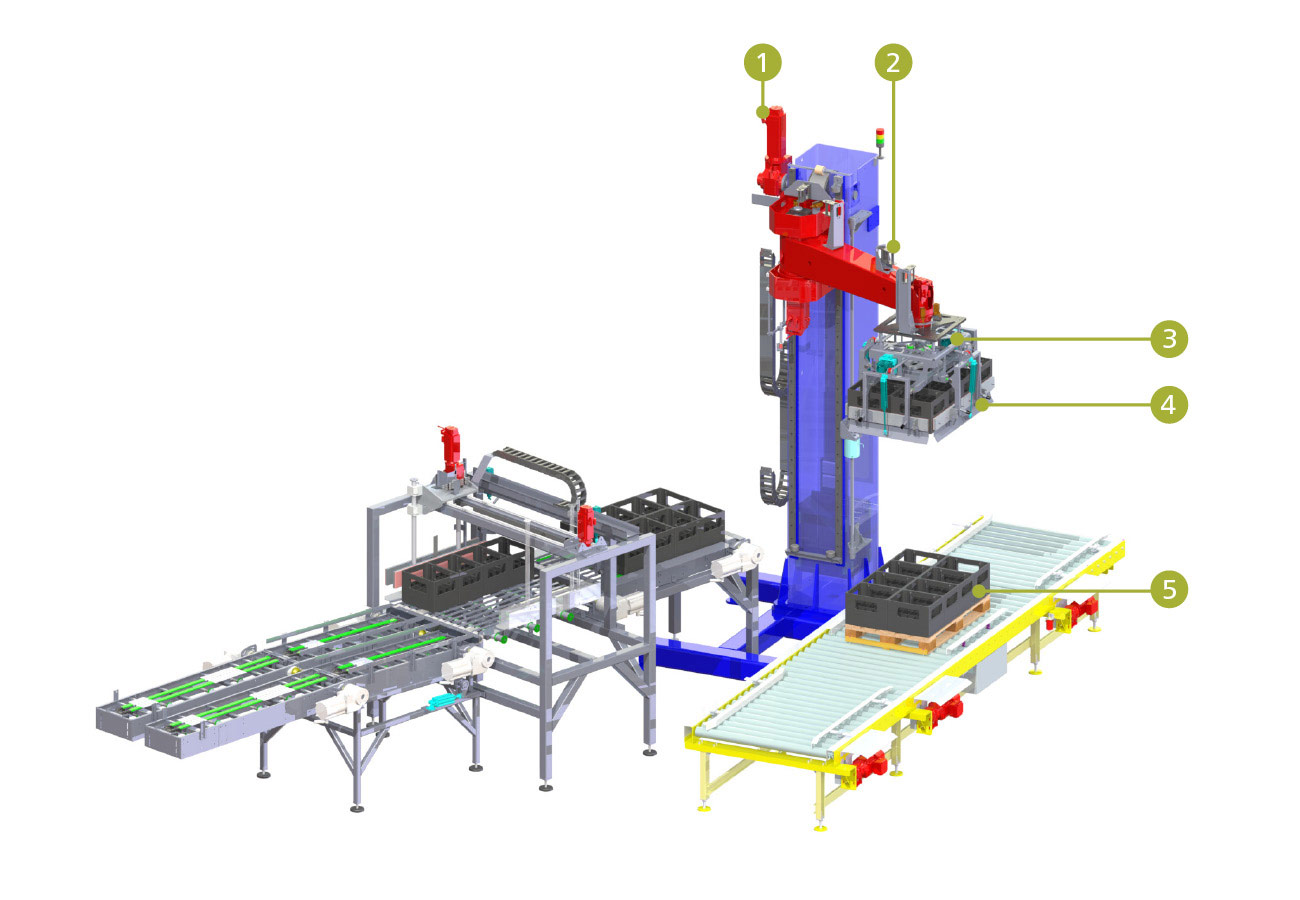

Column-type technology

BMS palletiser UNIPAL 107/108

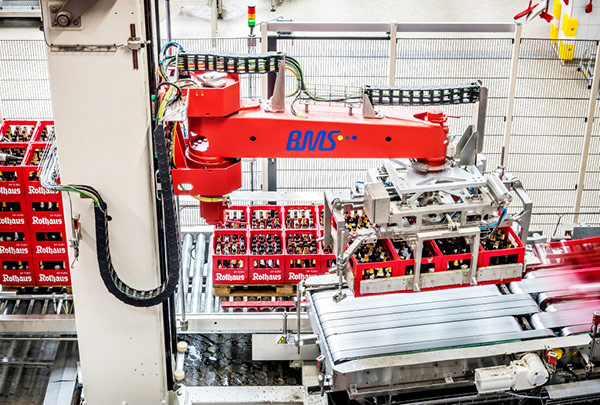

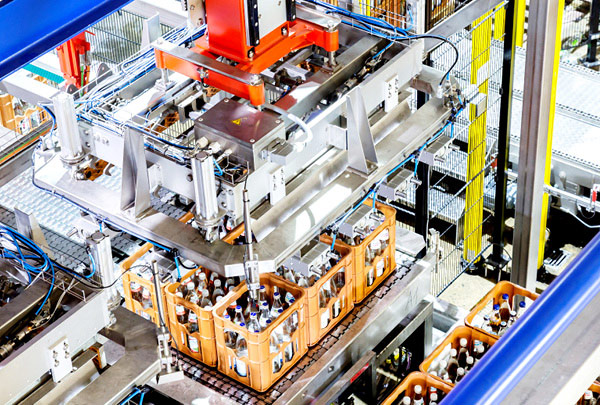

The column-type robots BMS UNIPAL 107/108 can be used in multiple ways for the palletising and depalletising of e.g. beverage crates, shrink-packs, multipacks or cartons. The column robots reach maximum speeds of 450 cycles/h and handle loads of up to 750 kg. They are available as swivel-arm or linear-arm robots. Due to their motion control system and specific application of counterweights these BMS column-type robots are extremely accurate and energy efficient. The product-optimised gripper systems also ensure optimal pack protection and high stacking quality. The column-type robots BMS UNIPAL 107/108 can be additionally fitted with quick-changeover equipment for the gripper system as well as with customised lifting and swivel or linear motions as optional extensions.

- Motion Control Siemens PLC und SEW drive technology

- Highly dynamic servo-technology and precision positioning

- Designed for high loads of up to 750 kg

- Perfectly adapted gripper heads with optional quick-release coupling

- Flexible application for handling crates, cartons, shrink-packs and multipacks

BMS Column-type palletiser – the UNIPAL 107/108 in operation

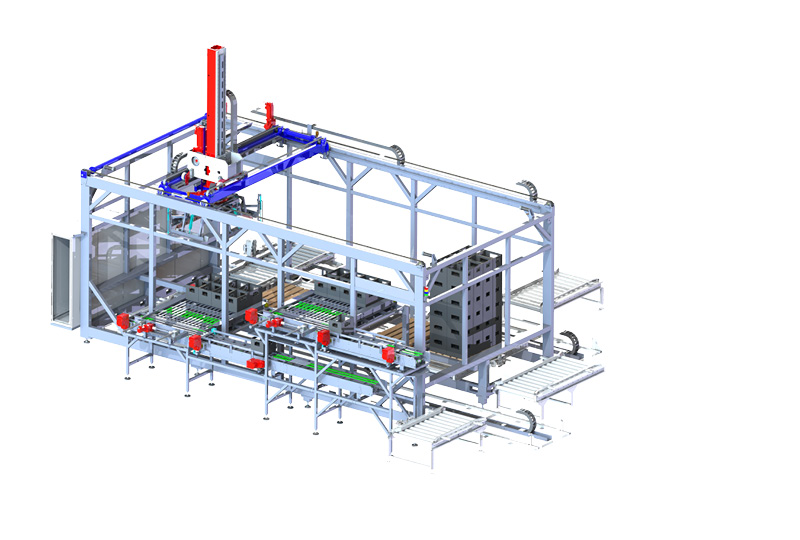

UNIPAL 108 – Depalletising plant

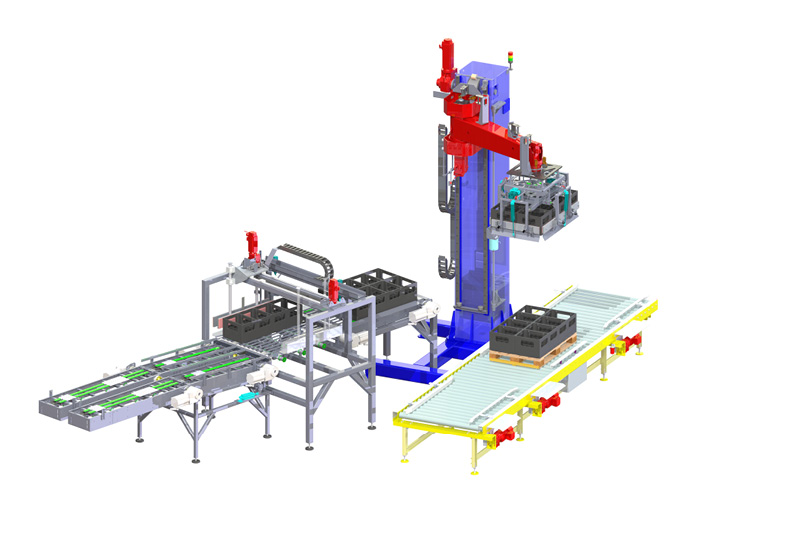

UNIPAL 108 – Palletising plant

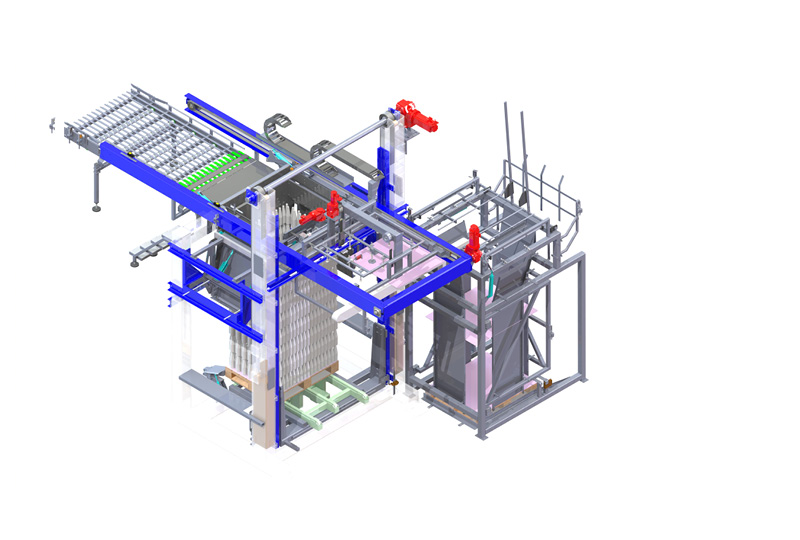

UNIPAL 108 – Layer gripper head

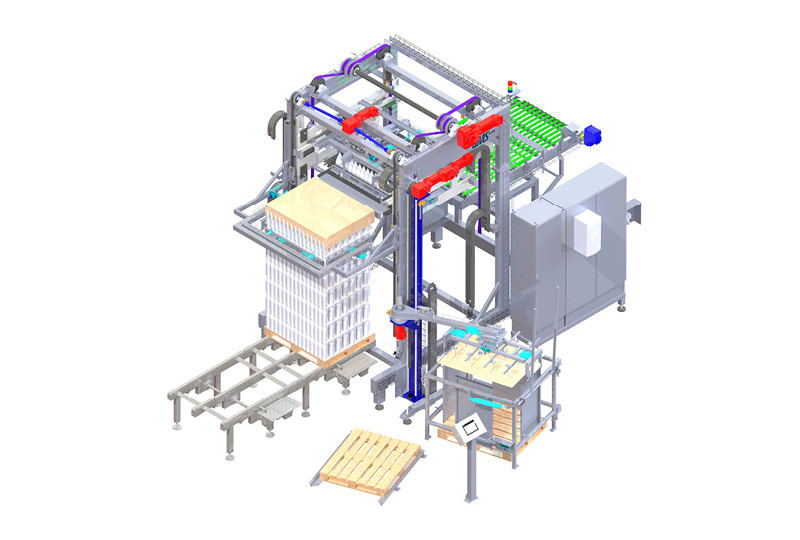

UNIPAL 108 – Hook gripper head

UNIPAL 107/108 - overview of technologies:

Product advantages of the UNIPAL

- Robust and durable machine design

- Designed for high loads

- Modular concept for flexible project planning

- Power-optimised machine design through state-of-the-art servo drives and the use of counterweights

- Proven Siemens PLC and SEW drive technology

- Individual and customer-specific machine size

- Modular design as linear-arm or swivel-arm robot

- Available as depalletiser, palletiser, combined palletiser or picking palletiser

Axis systems

Lifting carriage (Z)

- Stroke range 2,300mm (in standard version)

- Integrated counterweight

- Maintenance-free toothed belt system, no high-maintenance chain drives

- SEW servo drive technology

- INA linear guide for highest requirements

Swivel arm (W)

- Working radius 1,500mm

- Swivel range 210°

- SEW Servo drive technology

- Clearance-free Cyclo precision gearbox

Orientation axis (J)

- Orientation range 210°

- SEW Servo drive technology

- Clearance-free Cyclo precision gearbox

Linear axis * (X)

- Longitudinal travel 1,600mm (in standard version)

- Maintenance-free toothed belt system, no high-maintenance rack and pinion drive

- SEW servo drive technology

- INA linear guide for highest requirements

* only UNIPAL 107

Gripper heads

- Hook gripper head

- Clamping gripper head

- Roller gripper head

- Combination gripper head

- Special and individual gripper heads

System extension

- Handling of intermediate pads

- Layer preparation

- Grouping stations

- Individual modules

- Layer pusher

Select your language