Palletisers and depalletisers for every performance range

Palletising technology “Made in Germany”

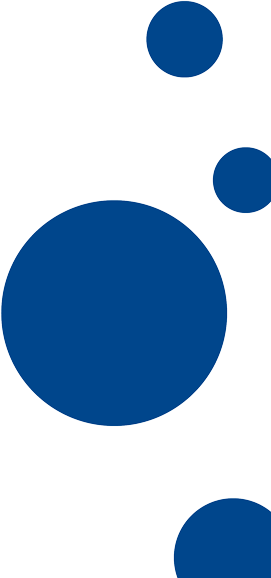

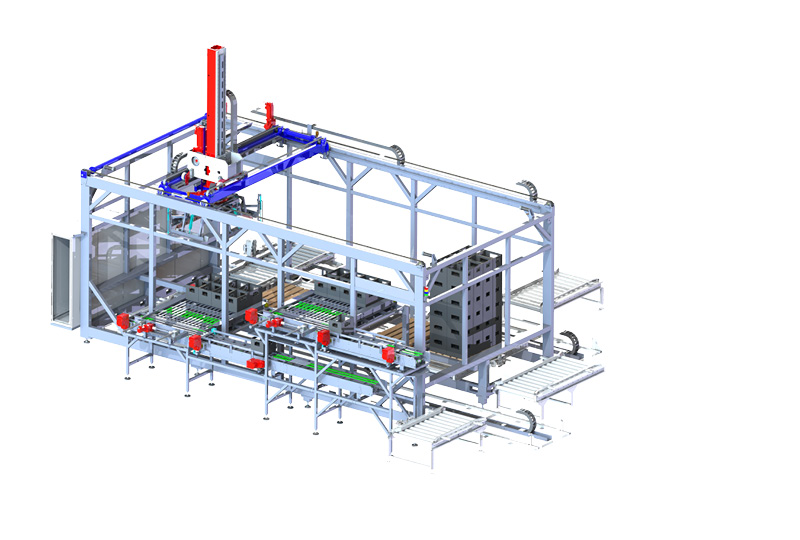

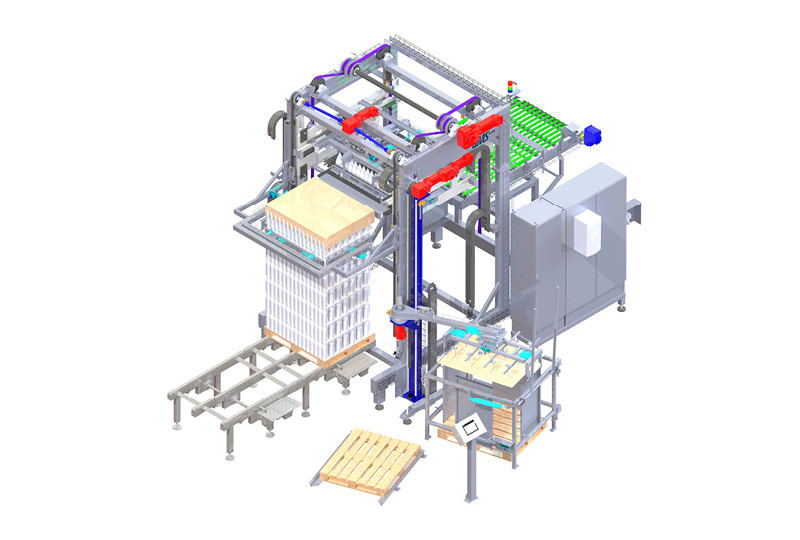

BMS palletisers and depalletisers are stable, compact machines that are designed for all performance ranges and packing requirements. Depending on the spatial conditions and specific requirements we also offer individually tailored solutions – using both column and portal technology.

The universal modular design enables the combination of any kind of palletising and depalletising. It is also possible to combine both functions in the basic machines. Featuring a compact design and high precision functionality our palletising systems meet the highest load requirements. The axes control and our wide range of product-optimised gripper systems additionally provide fast and reliable operation with maximum pack protection as well as high stacking quality.

The BMS UNIPAL series

Overview of UNIPAL palletising technology

Combined layer gripper head

For handling a wide spectrum of layers and packs.

Inserter of layer pads

Inserter and remover of layer pads

- Optional equipment for palletisers with integrated layer pad inserter or remover for every performance range

- Removal from magazine and handling with vacuum gripper

- Handling of layer pads with vacuum gripper

- Optionally available with integrated layer pad magazine

Combined row gripper head

For packing (repacking), the palletising of packs in rows and pallet handling.

Automated head change-over system

- When using different gripper head systems

- Z-axis with pneumatically controlled quick-release coupling

- Mounting element on gripper head

- Head change-over at the push of a button

Roller surface gripper head

For loading sensitive products such as cartons or shrink-packs.

Layer/row pusher

- Compact structure through integrated design

- Equipped with roller carriage or precision guides, depending on respective use

- High level of availability through optimised components

BMS machines

By your side all the way

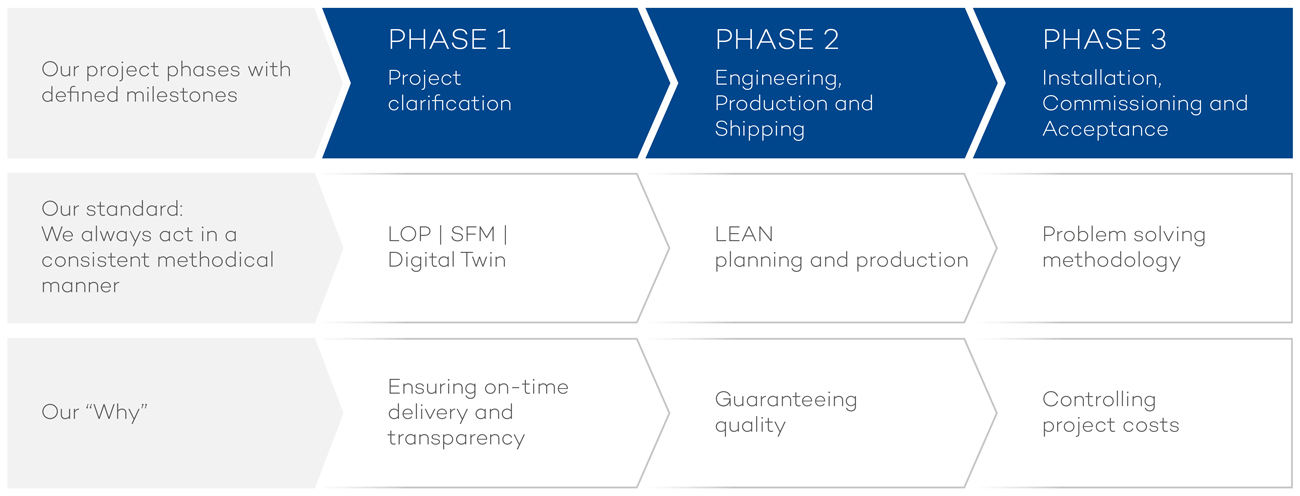

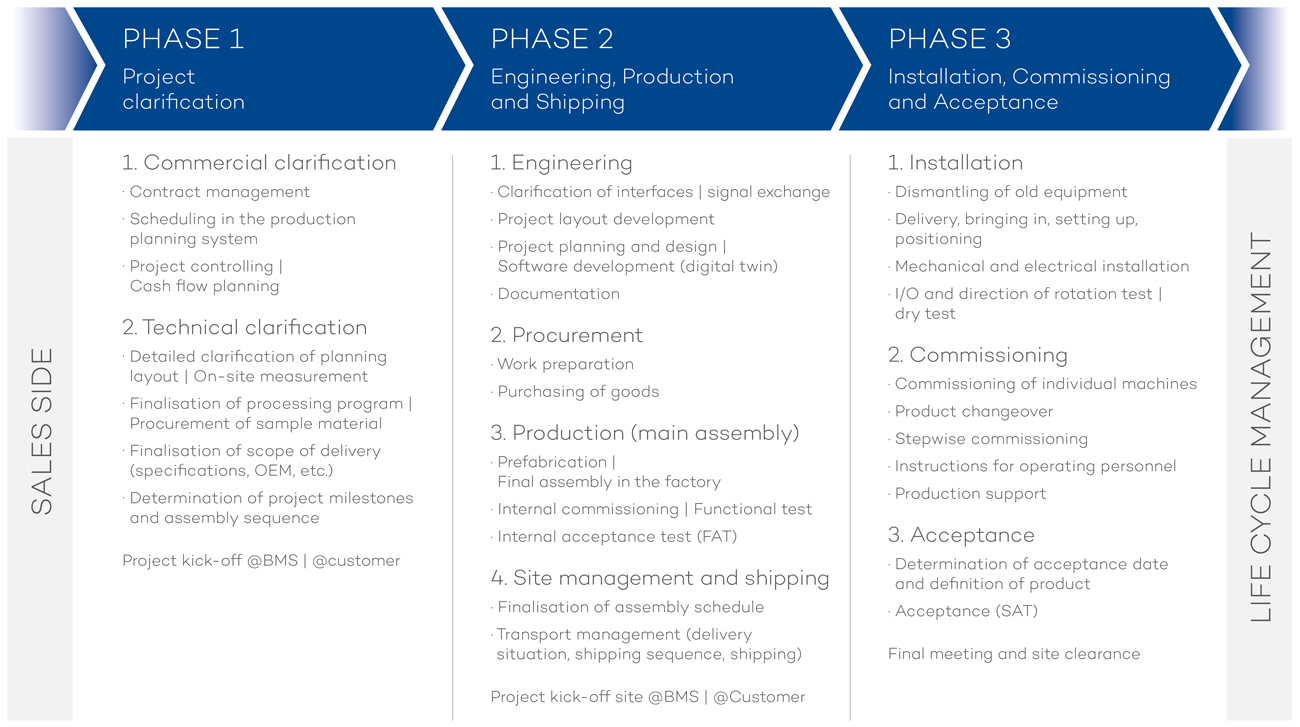

Our aim is for you to achieve your goals

From the first step of project development to the finished result. From the idea to consulting, project planning and construction to the ready-to-use end product, we are always on the lookout for customised solutions.

Our Project Management philosophy

Consultation and Project planning

Thanks to our comprehensive know-how in plant planning and project management, we advise our customers competently and purposefully in the run-up to an order. The result is maximum output and plant availability. Are you planning an effective filling system? Then talk to us. We not only integrate our machines into existing lines, but also project and plan effective and economical complete lines for glass and PET.

Design

Our experienced development and design team works out your individual machine or system on state-of-the-art 3D CAD systems. In addition, we use virtual commissioning, which leads to a considerable reduction in commissioning times - even for complex systems and applications. Performance analyses for unknown applications and early fault detection are thus already carried out in the sales phase..

Manufacturing and Installation

Our modern production facility on a production area of over 3,000 m² is ideally equipped for series production and one-off production. With our skilled personnel, our vertical range of manufacture and our optimised time management, we are able to manufacture and deliver outstanding quality products.

Our comprehensive preparatory work in the factory keeps on-site assembly times to a minimum. Our competent assembly staff trains your employees in operation and conversion issues.

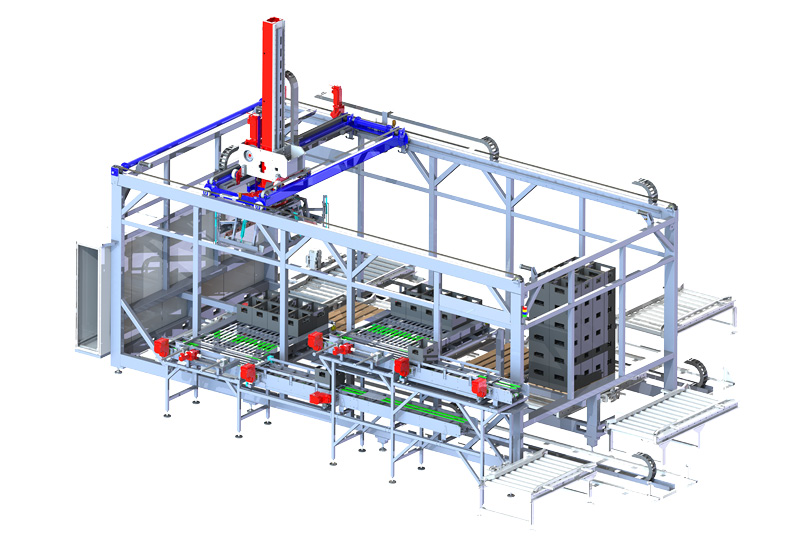

Palletisers, packers or conveyors as individual machines

Individual machines for the dry part and portal-type technology for customised solutions and systems

Fostering an innovation friendly approach and with the flexibility of a medium-sized company with firm roots in the region we take great pleasure in working hand in hand with our customers. Besides project planning of complete systems we also offer them individual machines that can be easily incorporated in the existing systems. Whether palletiser, packer or conveyor system, standardised or as innovative portal technology – at BMS the solutions are tailored to the customer’s needs and not vice versa.

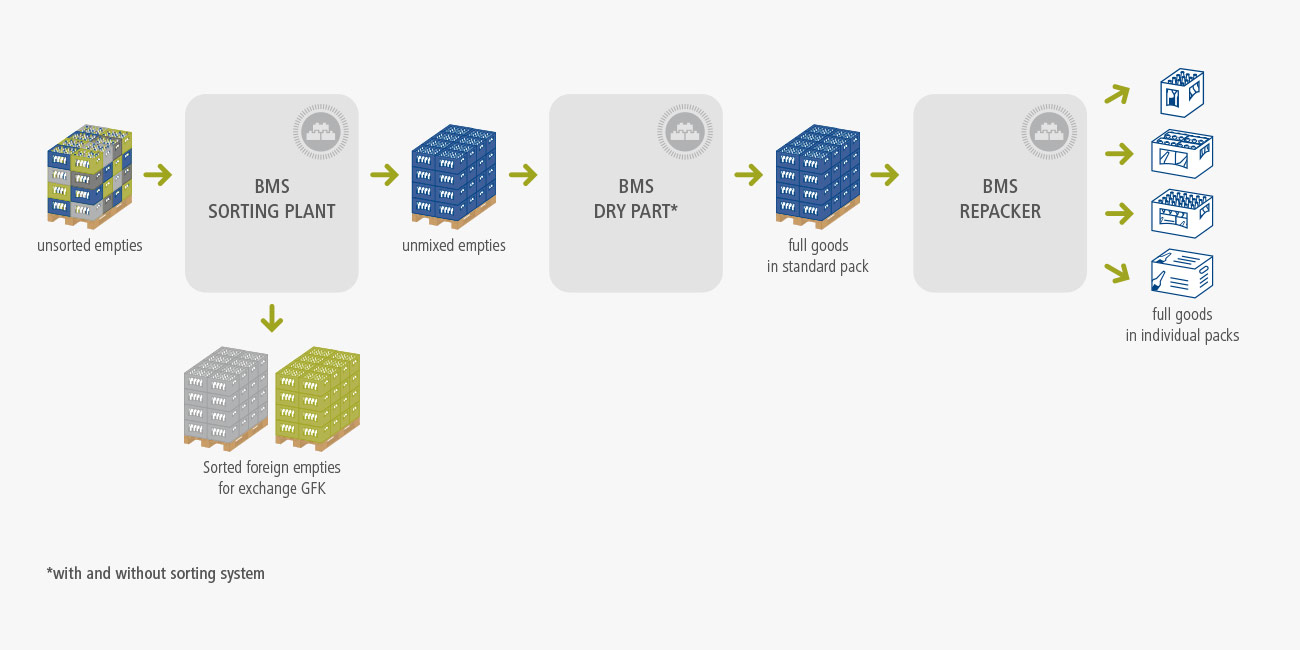

Systems

Over the past ten years BMS Maschinenfabrik has moved on from being a provider of individual machines for the dry area to a system specialist. Our plants are distinguished by robust machine designs that stand out with their easy operation and longevity. From the development to manufacturing and delivery all the way to installation – we cover the entire range of operations including the subsequent maintenance and service jobs – making sure that your dry area complete plant delivers an efficient and powerful performance at all times.

BMS – Your system provider in filling and logistics

Product portfolio

Precision machines “Made in Bavaria”

Development, construction, delivery, installation – all done today by BMS. Top product quality, contract compliance, promptness, a comprehensive service and flexible, tailored solutions are standards that are most important to us:

We are happy to advise you personally!

This email address is being protected from spambots. You need JavaScript enabled to view it.

Product management – By your side all the way

From the first step of project development to the finished result. From the idea to consulting, project planning and construction to the ready-to-use end product, we are always on the lookout for customised solutions.

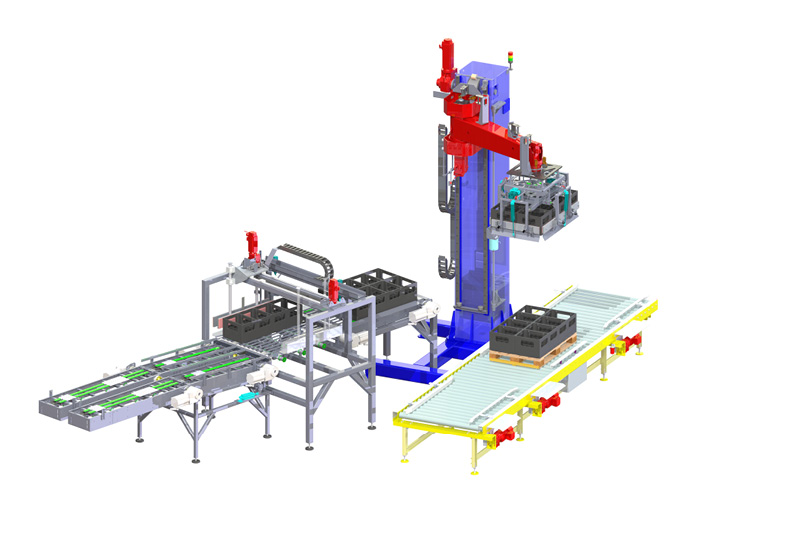

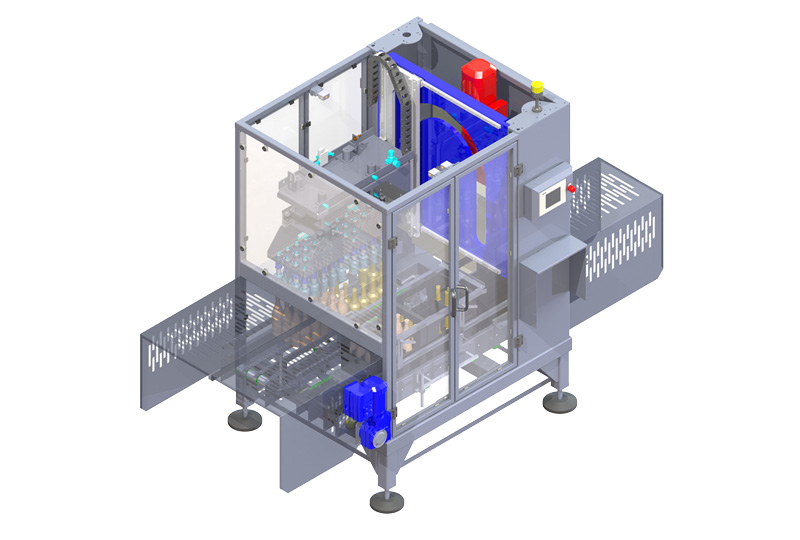

Packing systems – BMS precision machines

The BMS intermittent packers offer dynamic and flexible solutions for packing and unpacking as well as for sorting and repacking in all relevant capacities. Ergonomic in design these systems ensure excellent accessibility and guarantee high system availability.

Palletising – fast and reliable

Depending on the space conditions prevailing at the customer’s premises the individually tailored BMS palletising technology is available using column-type or portal-type technology. Open systems make the operation easier and speed up retrofitting and conversion jobs.

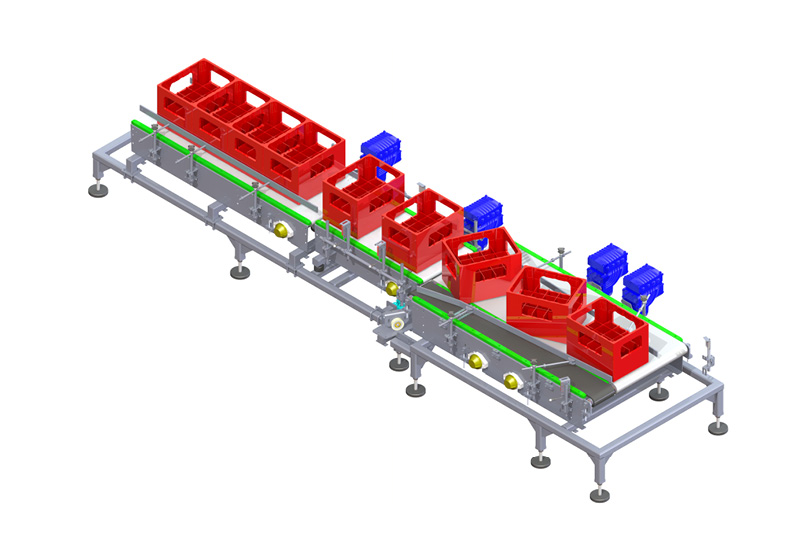

Powerful conveyor systems for every performance range

Solid designs of durable stainless steel cover the entire range of conveying systems for the wet and dry area of a bottling line. BMS conveyors ensure an excellent material flow at all times.

Systems and plants – tailor-made and dynamic concepts

As system provider BMS carries out the project planning and delivery of individual plants for the dry part, the sorting area and the repacking area.