Packers, unpackers, repackers and sorting packers for all performance ranges

Packing technology “Made in Germany”

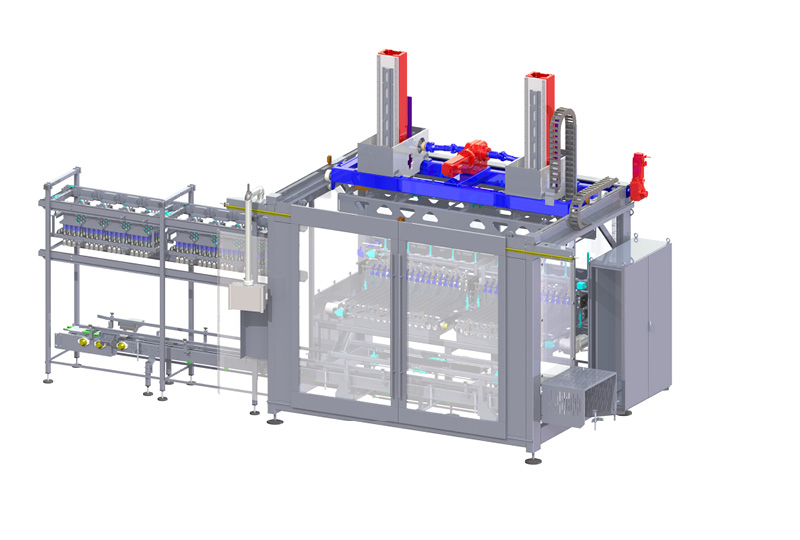

BMS Intermittent packers are available for all relevant performance ranges. As tried and tested precision machines they offer a highly dynamic and flexible performance for the packing and unpacking of common types of containers such as bottles, jars or cans in plastic, wooden or low-wall crates as well as cartons and trays. In addition to this, UNIPACK solutions are also used as sorting packers and repacking machines.

Besides our high-performance machines we also develop and manufacture packing machines for the small and medium performance range – individually adapted to your specific requirements.

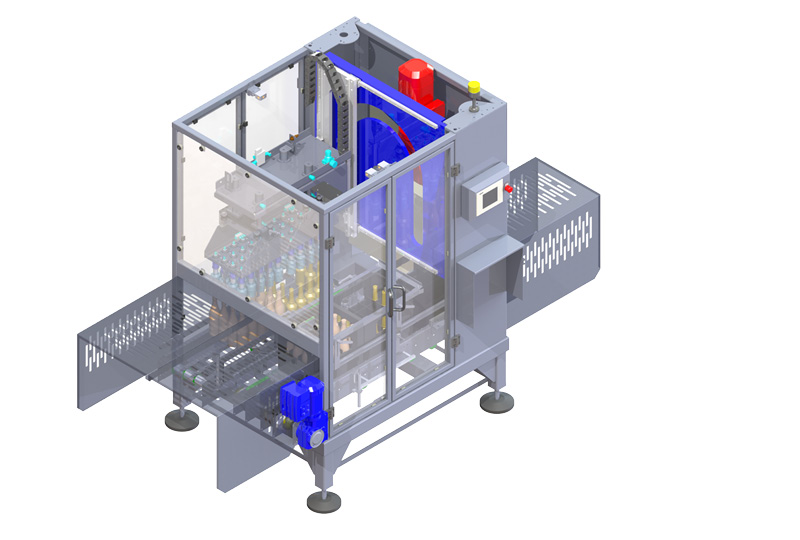

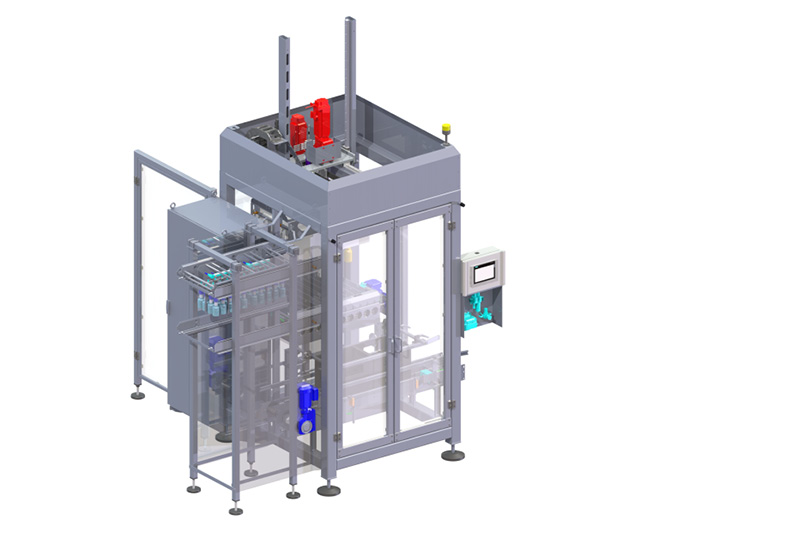

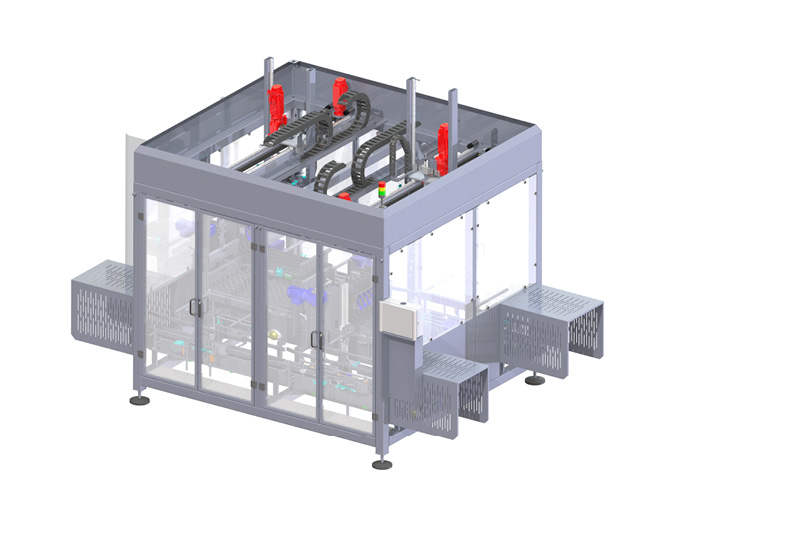

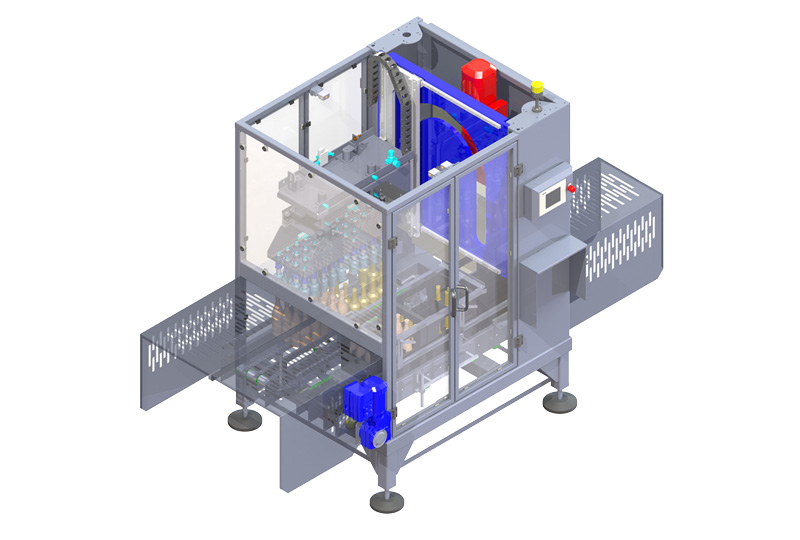

BMS packing machines of the UNIPACK series

UNIPACK portal-type machines – overview of technologies

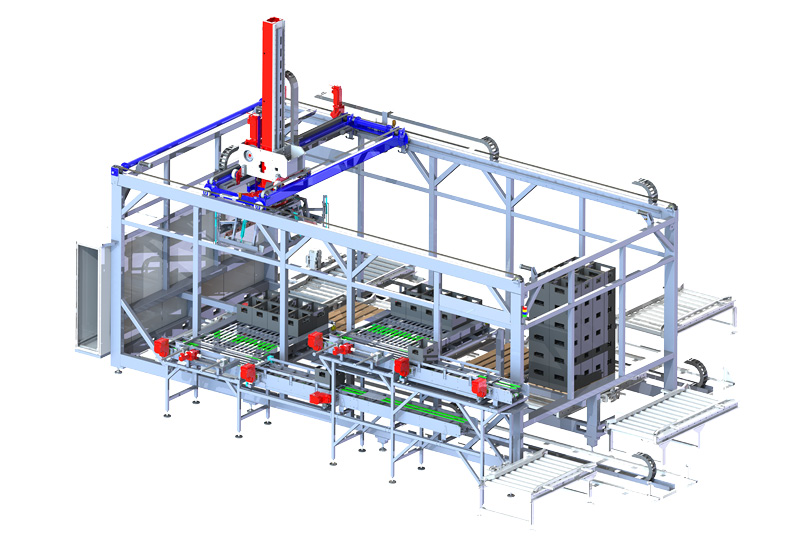

Gripper head changeover system

The automatic head changeover system has an integrated gripper head magazine and ensures a swift and easy change-over to different bottle and crate sizes.

Control system

The wiring and installation of control units for all BMS machines is according to VDE specifications. The control cabinets are integrated in the machines. BMS machines are operated using state-of-the-art Siemens control systems and motion control applications from SEW.

Long-life packing bells

Gripper heads with quick-release coupling for change-over without the use of additional tools are equipped at BMS with long-life packing bells as standard.

Perfect alignment of bottles

To achieve the best promotional effect of the bottles in the crates BMS provides special gripper heads with servo-controlled label orientation as optional equipment. Using photocells these gripper heads position the labels in such a way that these can be seen through the crate opening.

Control via cam plate

The gripper head used in BMS packing machines for small and medium capacities runs in high precision guides with a stable, low-maintenance lever junction and is actuated via a solid steel cam plate.

BMS clip-lock bottle orientation

To reliably prevent bottles with clip-lock bottles becoming stuck during unpacking the bottles are automatically turned outwards. In this way, any damage to bottles, crates and machines is ruled out.

Advantages of the BMS packers and unpackers:

- Base frame in a stable, welded distortion-free stainless steel design

- Compact and space saving design

- The modular design allows a quick and efficient retrofit to different bottles and crates

- Packing cam and cycles are freely programmable to achieve optimal cam tracks for all handled products

- Gripper head support with automatic format change

- Gripper head magazine with automatic coupling for quick change-over times

- Touch panel with intuitive user prompting and logical diagnostics feedback

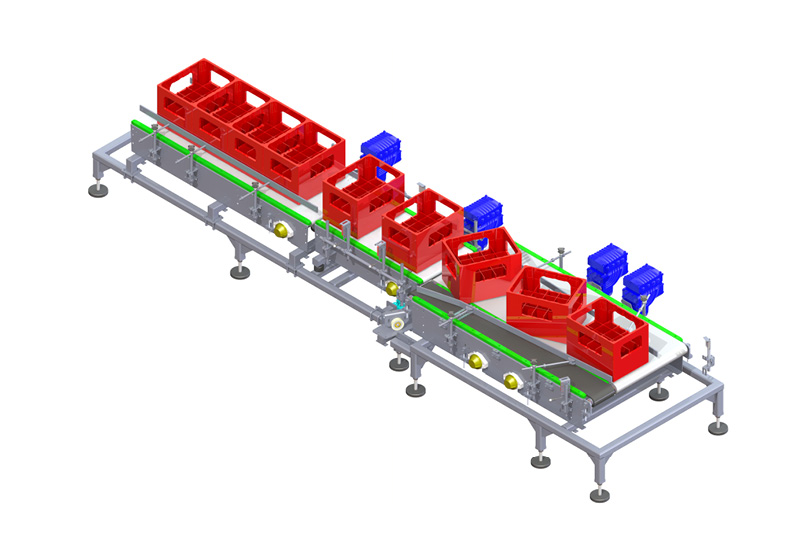

- Bottle guidance above mounted bottle table

- Bottles are lined up by means of lane separators, automatic lane adjustment available as optional equipment

Select your language