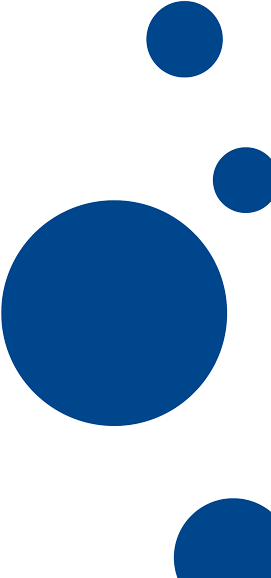

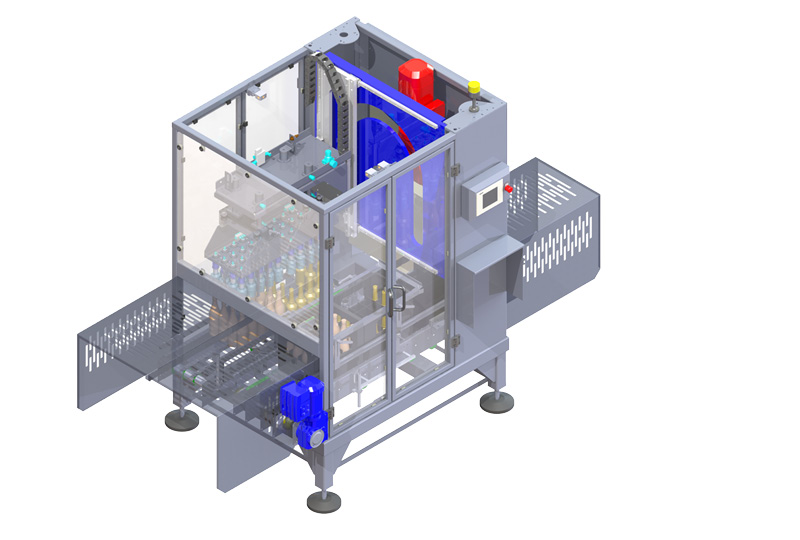

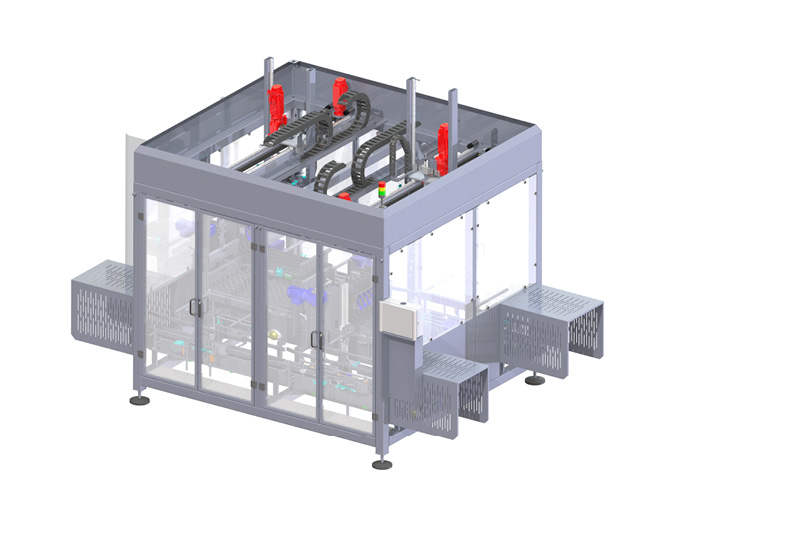

Cam-controlled packing machine

UNIPACK 100

The BMS cam-controlled packing machine UNIPACK 100 has been specifically designed for small and medium capacities. Here the gripper head runs in high precision guides with a stable lever junction and is actuated via a solid steel cam. The installed asynchronous drive with enhanced energy efficiency and performance is also practically maintenance free. With its modular design based on a stable, welded distortion-free stainless steel structure, the UNIPACK 100 allows an individual adjustment to very different containers and packs. The UNIPACK 100 is available as a packing or unpacking unit and also for T-configuration or H-configuration.

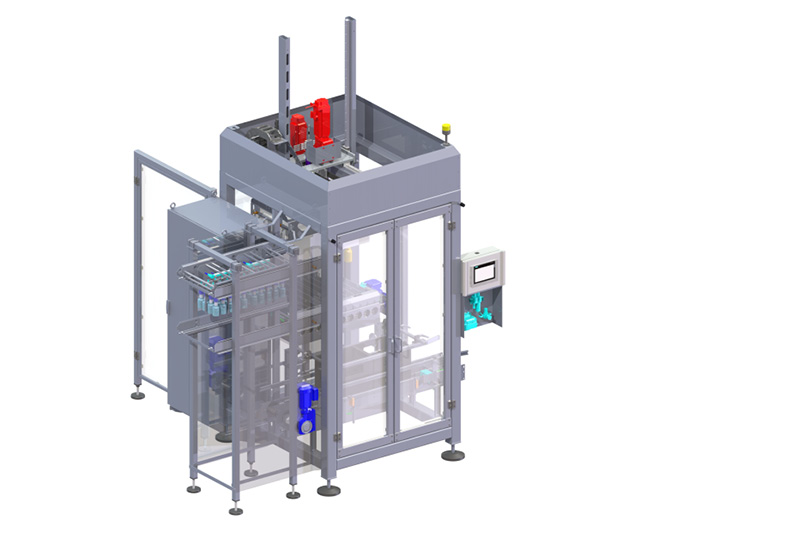

UNIPACK portal-type machines – overview of technologies

Bottle table

- Integrated vibrator and completeness monitoring

- Transfer panel between container transport and bottle table

- Container transport equipped with flat-top chains of steel or plastic or mat-type conveyor, depending on the respective task

Pack transport

- Integrated infeed and pack stopper

- Pack transport with steel flat-top chain

- Optimised railing

Packing bells

Optimised long-term packing bells adjusted to suit the product range

- Packing bell with gripper finger

- Packing bell with inflatable sleeve

- Packing bells for PET

- Packing bells for clip-lock bottles

- Packing bells for tight spaces

- Self-developed vacuum gripper

- Special packing bells

Gripper heads

- Rigid and axially adjustable gripper heads

- Individually adjustable gripper heads for individual pack

- Gripper heads for carton

- Repacker gripper heads for carton

Additional equipment

- Automatic label orientation

- Automatic clip-lock rotation

- Crate full monitoring

Select your language