A premiere for KEGs

A portrait of the new keg palletising system at Cölner Hofbräu P. Josef Früh KG

In 2021, Cölner Hofbräu P. Josef Früh KG significantly increased its production capacity and output. This meant that the hourly output of keg palletising had to be doubled – and maintaining the same footprint as the old plant. This challenge was solved using a plant prototype with the proven portal-type machines. This makes the keg palletising system very compact, highly flexible and particularly suitable for the output range in excess of 100 kegs per hour.

Cölner Hofbräu P. Josef Früh KG, or Früh for short, was founded in 1904 by Peter Josef Früh, just a stone’s throw from Cologne’s Cathedral.

In total, six different types of barrels and two types of pallets can be processed with the new system.

In total, six different types of barrels and two types of pallets can be processed with the new system.

In terms of annual production, the third-largest Kölsch brewery

In terms of annual production, Früh is now the third-largest Kölsch brewery with an output of 400,000 hectolitres. Beer has not been brewed at the headquarters since 1987, rather at brewing facilities in Köln-Feldkassel. The former area of the brewery and the residential premises of the Früh family are now used as a hospitality business. Alexander Rolff and Philipp C. Müller now head the Kölsch dynasty in the fifth generation.

The core product of the brewery is Früh-Kölsch, which comes in bottles, cans and various keg sizes. The product range is complemented by non-alcoholic Früh-Kölsch, Früh NaturRadler (shandy) and Früh Sport Fassbrause lemonade.

With 180 kegs/h simply not powerful enough

For Früh, however, this expansion of the beer business meant that the existing palletising and depalletising system for kegs had to be replaced. At 180 kegs/h it was simply not powerful enough, also it could not be expanded adequately. With the expansion investment that was required Früh pursued three clearly defined goals, Bodo Böttcher, technical manager, recalls: “First of all, we needed double the output capacity while maintaining the same footprint. As a second requirement, the new line was to be operated by the same staff team. And thirdly we wanted further functionalities such as an automatic alignment station for incoming empties that would reduce disruptions, an automatic infeed of other pallet formats as well as NVE/SSCC marking and transport security.“

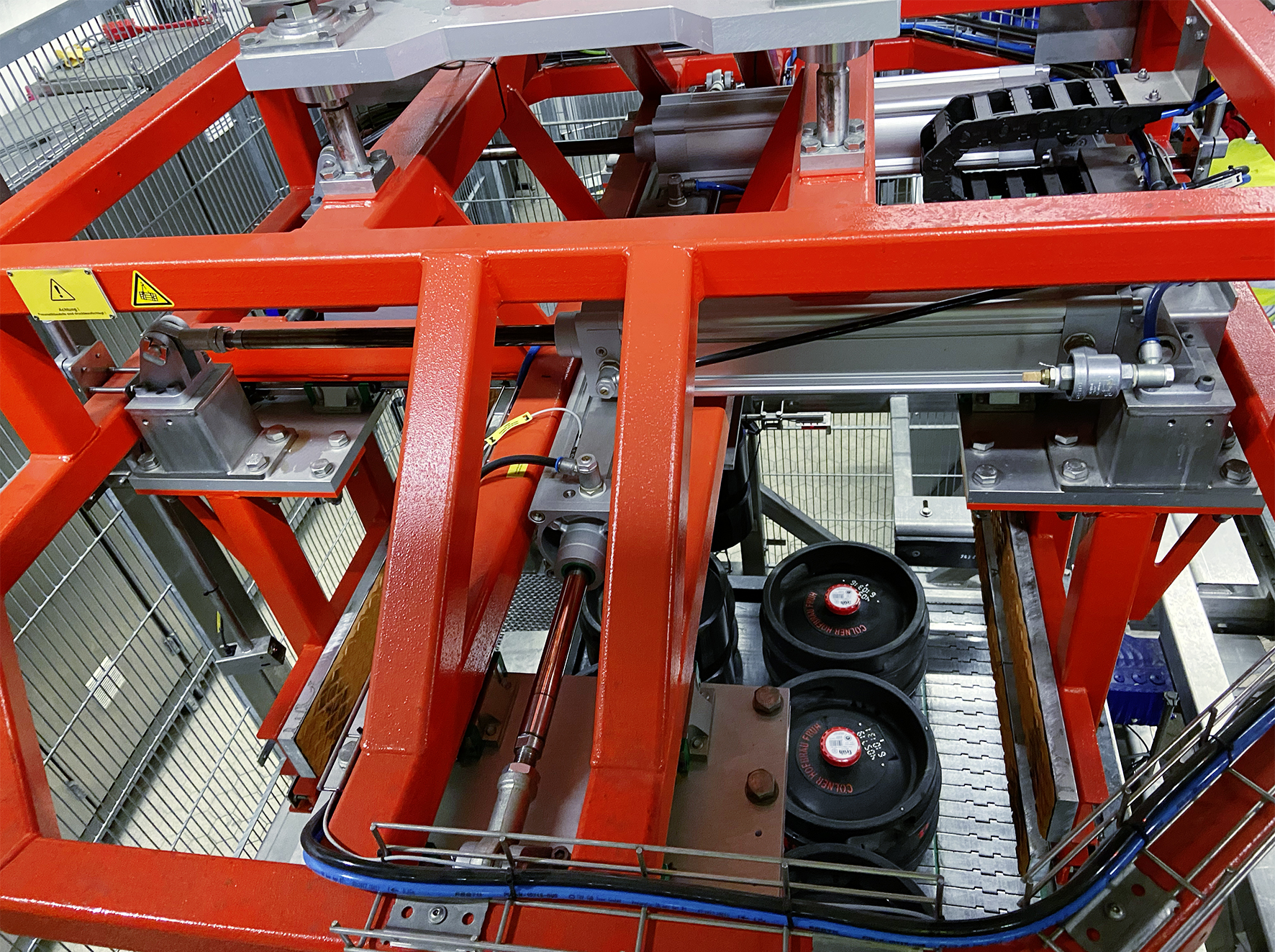

The depalletiser unloads the pallets with the layer pattern specified in the respective production mode

The depalletiser unloads the pallets with the layer pattern specified in the respective production mode

After carefully studying the solutions available on the market, Früh decided in favour of a prototype that used portal-type robots, i.e. a plant that was specifically designed for this type of application for the first time. There were good reasons for this, Böttcher emphasises: “On the one hand, we were convinced straight away by the robust engineering. The supplier had also been given a very positive rating by our professional colleagues. And last but not least, the prototype was the only way to implement the required overall package in the limited amount of space available.“ And for Früh, any structural changes to the buildings were out of the question.

The entire pallet handling is also carried out fully automatically

The entire pallet handling is also carried out fully automatically

Turnkey implementation in the tightest of spaces

The installation involved a 3-axis portal-type Unipal 106 EPL with integrated pallet handling for depalletising, a 2-axis portal-type Unipal 105 BPL for palletising, a Unicontrol pallet inspection system and a pallet conveyor Unitrans P with inline centering. This aligns the stacks of kegs or pallets if they have slipped during transport. This alignment is necessary to ensure a fault-free process and also the required high performance of the palletising system. The company Strapex/Signode was included in the project as OEM for the securing of the loaded pallets. The entire plant was implemented as a general contractor turnkey job. The dismantling of the old system was also included in the contract.

“In this way, a maintenance and operator-friendly plant with extremely reliable machine technology was installed in the tightest of spaces“, Böttcher sums up. Via a double feed station the pallets are conveyed to a centering system which aligns the pallet load to the Euro pallet format. From here the pallet is conveyed directly to the unloader which unloads the kegs onto a massive layer table. The pallet and the intermediate pad pallets are then stacked on a separate pallet stream. The kegs are separated and transferred to the existing conveyor system. The empty pallet is conveyed to the pallet check where it is inspected. If the inspection is not successful, the pallet is conveyed - also via a separate conveyor - to the “Not OK” pallet magazine which can, if required, be automatically converted and used as an “export pallet magazine” for the corresponding product.

After a successful inspection, the empty pallets are transported to the loader. This loads the pallets in up to two layers, depending on the production mode. The loaded pallet is then secured by a horizontal strapper and a vertical strapper using plastic cords. After securing of the pallet the pallet enters a stacking device which places the pallets on top of each other, depending on the production mode. From here the pallets, which are now ready for shipping, are conveyed to the double output from where they are picked up by the forklift operator. With regard to automation, the KEG dry part is designed as a stand-alone solution with signal exchange with the filling. A total of six different keg types and two pallet types can be processed.

: Only the static and dynamic design of the machine technology was adapted to the higher masses to be processed. In addition, a gripper head was developed for the new conditions such as weight and pack variety

: Only the static and dynamic design of the machine technology was adapted to the higher masses to be processed. In addition, a gripper head was developed for the new conditions such as weight and pack variety

„Superb operation from the very first day“

“As the first implemented KEG line ever, the solution ran perfectly from day one. The concept with the well-proven portal-type system worked excellently”, Böttcher recalls. Which is not really surprising, as the system engineering operates in the same way as with beverage crates. Merely the static and dynamic design required adjustment to the larger masses. In addition, a gripper head was developed to cope with the new conditions such as weight and pack variety.

“Particularly the reduced amount of conversion work required for pack changeovers as well as the new functions mean a significant reduction in work and time”, Böttcher is delighted to add. For instance, when changing from 15 l kegs to 50 l kegs the different keg height is adjusted via the programme preselection. The fine adjustment is then carried out by the palletiser with its sensor system. To perform the changeover the operator merely has to adjust a light barrier at the unloader and two position holders on the loader to enable the exact clamping of the new layer pattern.

Problem Covid-19: if there is no demand, there is no palletising

The installation and commissioning under the sudden Covid-19 conditions was a huge challenge. Not only with regard to the extensive hygiene measures. Böttcher goes on to explain: “Just when we were about to start commissioning, the demand for draft beer stagnated due to the Covid restrictions. And no demand means no filling and also no palletising. The actual implementation, including the final acceptance was therefore delayed through no one's fault.”

Performance beyond reproach

Despite the Covid pandemic, the performance was excellent. And it remains so to this day, Böttcher concludes: “Both the plant and the cooperation met our expectations and the work was carried out to our fullest satisfaction. Also the subsequent order for another plant says it all, I think.“

In this way, the KEG palletiser is very compact, highly flexible and particularly suitable for the output range above 100 barrels per hour

In this way, the KEG palletiser is very compact, highly flexible and particularly suitable for the output range above 100 barrels per hour

Kölsch – the history of a beer specialty - source: frueh.de

The first brewer from Cologne to be mentioned in writing was Henricus Medebruwer (“mead brewer”) from Bechergasse in 1285. It was not until over 100 years later, in 1396, that the Cologne brewers’ guild was founded (Zunft der Kölner Brauer). However, they did not brew Kölsch as we know it today. At that time, instead of using hops, beer was brewed with gruit (a mixture of various herbs) and underwent “wild fermentation”. The people of Cologne seemed to like it – and in 1392, for instance, 32,000 hectolitres of gruit beer were already being brewed.

It was not until the beginning of the 15th century that hops were introduced into Cologne’s beer and sold to the people of Cologne as Keutebier. This was the starting shot for a remarkable success story: today, the top-fermented light, yeasty beer is considered a regional specialty and is only allowed to be made in Cologne and the surrounding area, and only served in the so-called Stange glass.