Decades of experience

Development, manufacturing, delivery, installation, commissioning – all of these phases are implemented by us at BMS. After this, the customer can also rely on us for maintenance and conversion jobs. In this way it is possible to offer the highest level of functionality, save personnel and minimise maintenance and retooling times. These are benefits that enable you and your company to make consistent progress. Upon request, we can take the entire project management off your hands and also integrate existing machinery. All of our services and efforts are implemented with your performance, your success in mind.

With in-depth know-how in plant planning and project development we are able to offer our customers professional and tailored consulting services in the pre-order stage. This results in a maximum level of productivity and plant availability.

Perhaps you are making plans to set up an efficient bottling line? Talk to us! Apart from integrating our machines in existing plants we also carry out the full project planning and project management for an effective and cost-efficient complete plant for glass and PET.

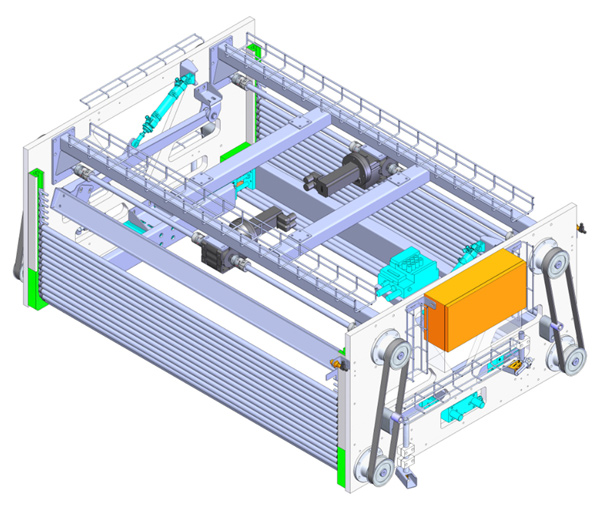

Our experienced development and design team use state-of-the-art 3D-CAD systems to design your individual machine or plant. Being near to the production our specialists are always in a position to ensure practical and efficient solutions.

Covering an area of over 3,500 m² our production site is excellently equipped for series and individual production. Thanks to our specialist staff, our vertical manufacturing and optimised time management we are able to make and deliver products of outstanding quality.

Extensive preassembly work carried out in our factory enables us to restrict assembly work on site to a minimum. Our competent service engineers train your staff in all issues regarding the correct operation and retooling.

By maintaining an extensive stock of spare parts we can respond quickly in the event of any trouble and thus maximise availability and machine uptime.

BMS After Sales & Service Product Portfolio

A partnership that helps you move forward. After Sales & Service from BMS.

In addition to the proven packers, palletisers and conveyors, the focus is on the BMS After Sales & Service offering. We support our customers in the maintenance, inspection, overhaul, retrofitting and repair of their machinery to ensure long-term and optimal use.

Our focus is on the longevity of the machines, good and fast service and the highest possible productivity. In short: on reliability.

And it is the individual needs of the customers that drive us at BMS in the development of products and services. That's why we consciously seek proximity to our customers, visit them in their factories and find out what they need. Our dedicated team works continuously to anticipate your needs and fix problems even before you notice them.

OUR GOAL: The best possible service at all times for maximum productivity and plant availability.

BMS After Sales & Service Products at a glance:

Retrofits/Upgrades

- Control exchange from the TIA series

- Central ubrication

- Handling parts trolley 2.0

- Divisible rollers

- Nail rollers

Spare Parts

- Customized spare parts and overhaul packages

- In-House-Overhauls

- Emergency spare parts packages/Keep it Run

Services

- Training of operators and maintenenace staff

- 24/7 Support

- Line relocations

- Different Service Level Agreements

Spare Parts

Increase flexibility and functionality.

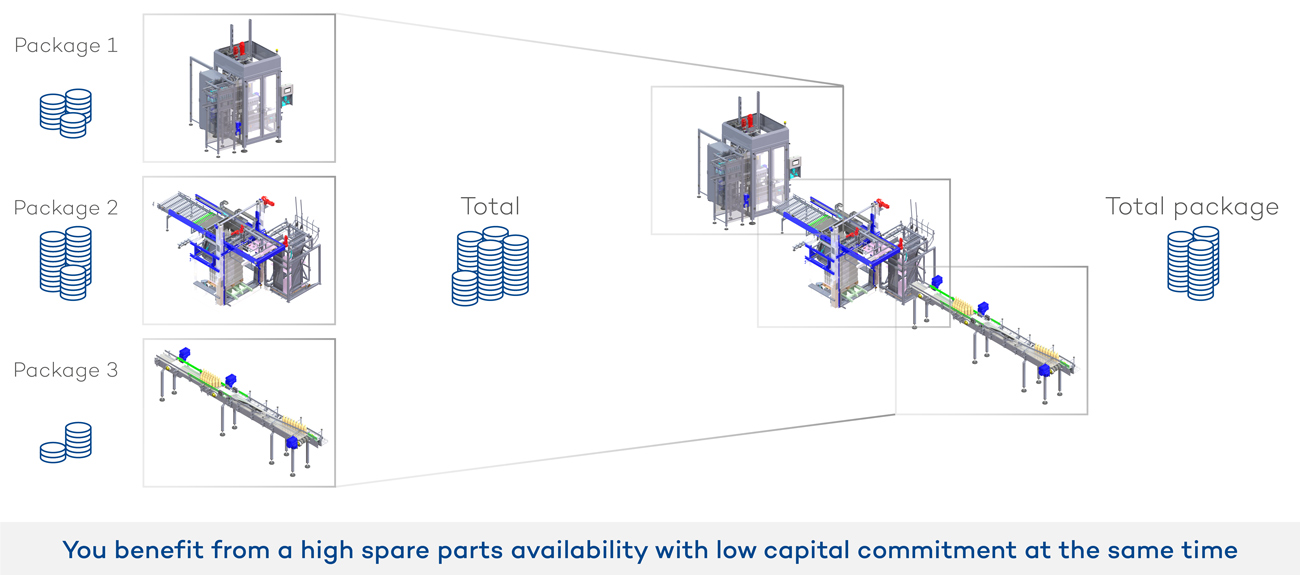

As a leading manufacturer of machines and systems for the beverage and food industry, we use our experience to optimise your spare parts inventory.

The more your spare parts warehouse is professionalised, the better the BMS machines and systems are protected from long-lasting and unplanned downtimes and the machine and system availability increases.

We will advise you personally on customised spare parts and overhaul packages as well as in-house overhauls: This email address is being protected from spambots. You need JavaScript enabled to view it.

BMS Spare Parts Portfolio

- Customised spare parts and overhaul packages

- In-House-overhauls

- NEmergency spare parts package/Keep it Run

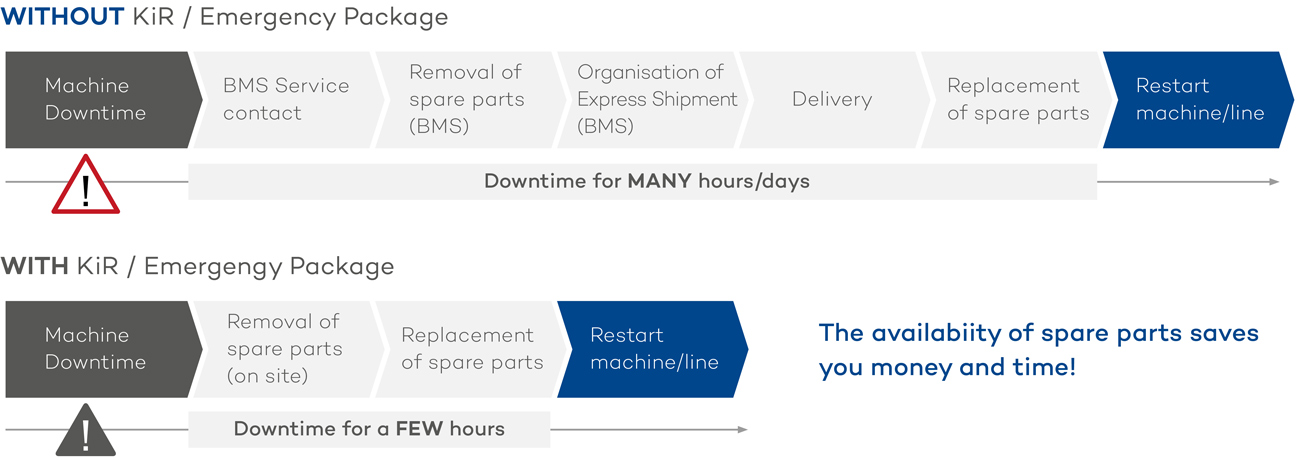

Emergency spare parts package/Keep it Run

In the event of machine downtime, BMS offers a customised emergency spare parts package/Keep it Run to achieve the goals of high machine and system efficiency.

- BMS identifies the spare and wear parts for your machines/lines. Based on this analysis we can offer you a tailored emergency package for your specific needs.

- Cross-comparison: means the spare parts that are identified as "the same" can be reduced to a minimum in your spare parts warehouse (no double stock-keeping and capital commitment).

Benefits

WITH Emergency spare parts package/Keep it Run

- Productivity instead of reactivity

- Customised solutions in terms of spare parts availability

- Many years of experience of BMS

- High degree of machine and line availability = higher degree of OEE

- Cost optimization and lower capital commitment

BMS Upgrade Portfolio

Customised upgrades for more performance, efficiency and sustainability of machines and plants from BMS.

With the upgrades for BMS machines and systems, our customers can implement new applications and function extensions and thus realise new customer requirements, work more profitably or specifically increase their added value. BMS upgrades for state-of-the-art and sustainable technology.

Retrofits

Our customised retrofits for BMS machines and systems enable agile adaptation to current market trends.

This enables our customers to react to rapid changes in the market environment by processing new packaging and bottle formats without any problems. With BMS retrofits, the focus is always on taking individual customer needs into account. We offer retrofits for BMS machines and lines that increase their flexibility and functionality.

We will be happy to advise you personally: This email address is being protected from spambots. You need JavaScript enabled to view it.

UPGRADE 002

Control system exchange to current TIA series

Your advantages

- The TIA controller keeps plant availability permanently at the highest level

- Faults are noticeably reduced

- TIA is established as the latest programming standard

- All spare parts can be procured cost-effectively, quickly and for years to come

- Digitalization connection e.g. remote control and improved diagnostic tools

- Conversion can be realized in approx. 2-3 days

- Suitable for all machine types

Your benefits

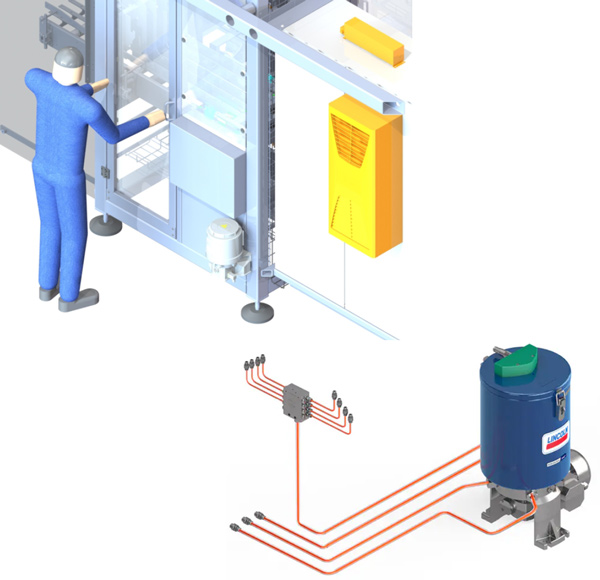

UPGRADE 003

Automatic central lubrication

Your advantages

- Individuell programmierte Schmierintervalle

- Reliable lubrication without the need for personnel

- Optimized lubricant consumption

- Increased operational safety and plant availability

- Self-monitoring of the system; all necessary information in the control panel

- Conversion can be carried out in approx. 1-2 days; also possible in conjunction with a maintenance measure

- Suitable for all machine types

Your benefits

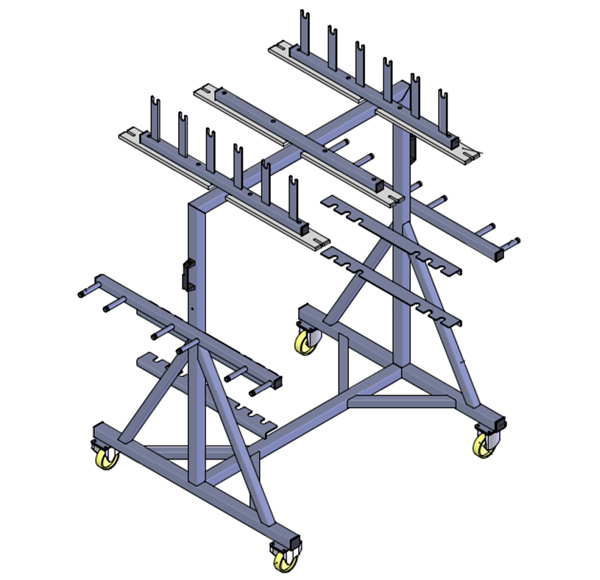

UPGRADE 004

Plug & Store Handling trolley

Your advantages

- Professional storage of clothing parts on a compact transport unit

- Damage to clothings is minimized

- Disturbances are noticeably reduced

- Ergonomic access to the clothings

- Flawless appearance and long service life of the clothings guaranteed

- Suitable for UNIPACK 2.0

Your benefits

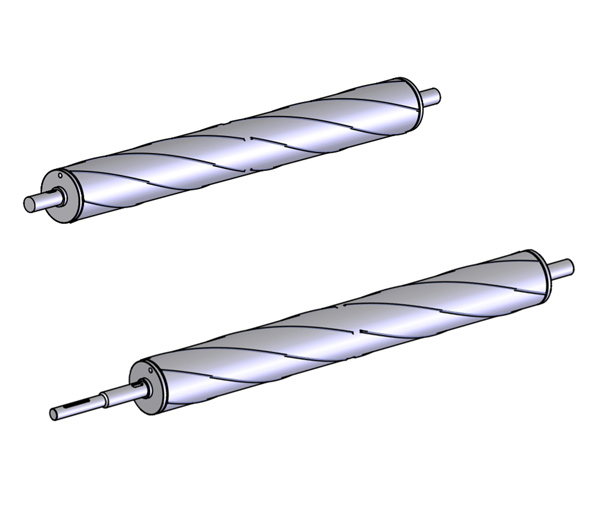

UPGRADE 005

Divisible rollers for blinds head

Your advantages

- In case of repair: Simple replacement of individual rolls without dismantling the roll carpet

- Simple repair of wear damage to coverings

- Faults are noticeably reduced

- Increased machine availability

- The changeover time for this maintenance task can be considerably reduced

Your benefits

UPGRADE 006

Traction roller for pallet transport

Your advantages

- Increased system availability through optimised empty pallets

- Disturbances are noticeably reduced

- High grip on icy or wet empty pallets when stored outdoors

- Traction roller is available in two versions: with drive shaft or running with the pallet

- Can be installed or converted in conjunction with a maintenance measure

- Suitable for all pallet transporters

Your benefits

UPGRADE 007

Upgrade of existing (asynchronous) drives to Movigear Generation C

Your advantages

- High energy savings of up to 50% per motor

- The compact design reduces the required installation space for these drives

- High reliability and performance of the drives

- Reduced noice level

- Economic advantages due to optimised storage costs for spare parts

Your benefits

UPGRADE 008

Rotation speed adjustment for crate turning station

Your advantages

- Individual adjustment of the rotation speed

- Short reaction times to changes in crate quality

- The rotation speed is adjusted without any intervention in the PLC

- SKU parameters remain unchanged by adjusting the rotation speed

- Rotation speed can be changed by the operator

- Upgrade can be done during operation

- Additional information in the touch panel

Your benefits

UPGRADE 009

Production monitor

Your advantages

- Cost efficiency: Coast causes for production downtimes are identified and continuously reduced

- Time savings: fast response time for your operators and line managers

- Operation: easy to use and quick to learn

- OEE increase: through live visualization of the line, faults can be identified as quick as possible

- Downtimes are significantly reduced

- Individaual programming for your line

- OEM‘s can be included

Your benefits

UPGRADE 010

MOVIAXIS® to MOVI-C® modular

Your advantages

- MOVI-C® modular maintains the system availability at the highest level

- Long term future proof availability: all parts can be procured cost-effectively,quickly and for years

- Conversion can be carried out in 2-3 days

- Suitable for all machines running at MOVIAXIS®

- Energy efficient and therefore lower operating costs

- User friendly software leads to intuitive commissioning

Ihr Nutzen

Services

Decades of experience – Our performance is your success.

Meeting the diversity of customer requirements is an important claim at BMS.

Therefore, comprehensive service is a matter of course for us. We are ready for action whenever you need our services.

Line training and handling

The most important thing when operating a line is line efficiency. Disturbances and downtimes must be avoided. We train the operators.

Your adventages

- Analysis of the line processes

- Increase in line performance/efficiency

- Cost reduction through optimized processes

- Advice for increase in performance of individual machines (e.g. poor empties)

- Trained staff - employee satisfaction is increased

BMS 24/7 with ticket system

- Including escalation in the event of a plant shutdown via text message to Head of Service

Our policy

- In the event of a plant shutdown the tickets are handled with the highest priority

- Also outside business hours, whenever possible

- BMS service engineers put their heart into delivering intelligent solutions

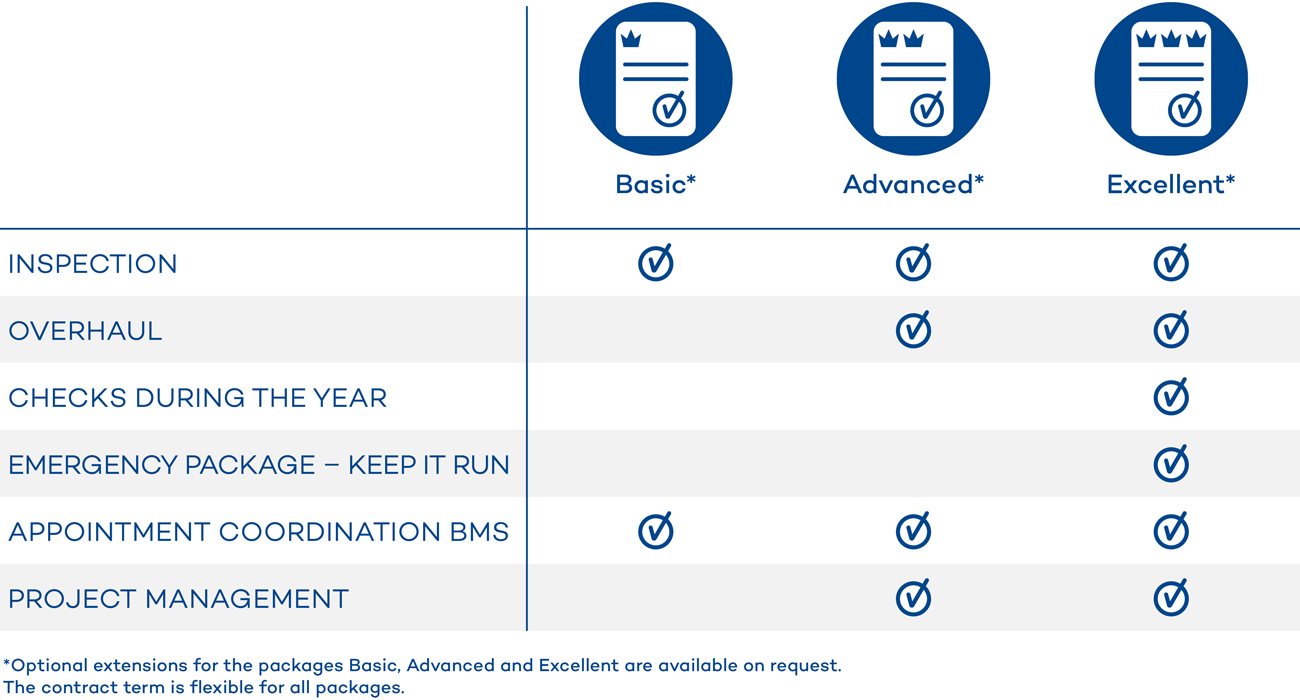

Service Level Agreements

Through the BMS maintenance models, we offer our customers optimal support for the care and maintenance of their BMS machines and systems. A professional execution of inspections and overhauls is crucial to ensure the reliability and efficiency of their BMS machines and plants. In order to meet the specific requirements of our customers, it is possible to flexibly add further options to the Basic, Advanced and Excellent packages.

We will be happy to advise you personally on customised maintenance contracts: This email address is being protected from spambots. You need JavaScript enabled to view it.

Overview

Basic

- Annual inspection incl. report with spare parts recommendation

- Inspection on the basis of the 3D model incl. digital recording of open points

- Appointment coordination by the customer BMS Appointment allocation

Optional

- Man days with individual focus

- Emergency package - Keep it Run

- Line training and handling

Advanced

- Annual inspection incl. report with spare parts recommendation

- Inspection based on the 3D model including digital recording of open points

- Including services, spare parts and final operator training

- Including project management

- Appointment coordination by BMS

- Proactive appointment allocation by BMS

Optional

- Man days with individual focus

- Emergency package - Keep it Run

- Line training and handling

Excellent

- BMS Jump-On process: preparatory inspection and overhaul

- Annual inspection including performance analysis and report with spare parts recommendation

- Inspection based on 3D model including digital recording of open points

- Including services, material and final review

- Including intra-year inspection of the system for performance and efficiency

- Including Keep it Run - emergency package

- Including project management

- Appointment coordination by BMS

- Proactive appointment allocation by BMS

Optional

- Man days with individual focus

- Line training and handling