Twice the output, same footprint

A portrait of the new packing and palletising solution for party kegs from Krombacher Brewery.

The Krombacher Brewery, first mentioned in a document in 1803 and family owned for generations, is now Germany’s largest private brewery and one of the most modern in Europe. Its flagship, Krombacher Pils, was once again Germany’s favourite beer last year. In addition, the company Krombacher has built up a successful family of brands. Besides the popular products Krombacher Radler (shandy), Krombacher Alkoholfrei (alcohol-free) and Krombacher Weizen (wheat beer), further successful products have become established in the beverage market over recent years, these being Krombacher’s Fassbrause, Krombacher 0.0%, Krombacher Limobier and Krombacher Brautradition.

These are complemented by non-alcoholic soft drinks which include some very well-known brands. Milestones on this path “from brewery to beverage supplier“ were the acquisitions of brand rights of Schweppes, Orangina and Dr Pepper. Together with these brands the company entered the non-alcoholic soft drinks sector in 2006. The traditional brand Vitamalz followed in 2016. With effect from August 1, 2022 the Krombacher Group has also taken over Heil- und Mineralquellen Germete GmbH, based in Warburg.

„It was really a matter of centimetres." Due to the cramped spatial conditions, Krombacher decided to install a column loader...

„It was really a matter of centimetres." Due to the cramped spatial conditions, Krombacher decided to install a column loader...

The impact of Covid-19 has been manageable

The second financial year in the Covid pandemic has also had an impact on the Krombacher Group, but on a relatively manageable scale when compared with the sector as a whole: a total output of 7.335 million hectolitres was achieved across all brands – this representing a drop of 0.9 percent. The parent brand Krombacher suffered a year-on-year loss of 2.3 percent, ending up with an output of 5.590 million hectolitres. The performance of the non-alcoholic soft drink family was again very encouraging. Output increased by around five percent to 1.453 million hectolitres. A key driver here was once again the Zero variants. The share of non-alcoholic products in the Krombacher Group’s total output thus rose to around 38 percent in 2021. “Especially in these difficult times, it has become evident that our strategy of consistent diversification of the product and packaging spectrum enables us to meet the diverse wishes and needs of the market in the best possible way“, comments Uwe Riehs, chief marketing officer, on the annual results.

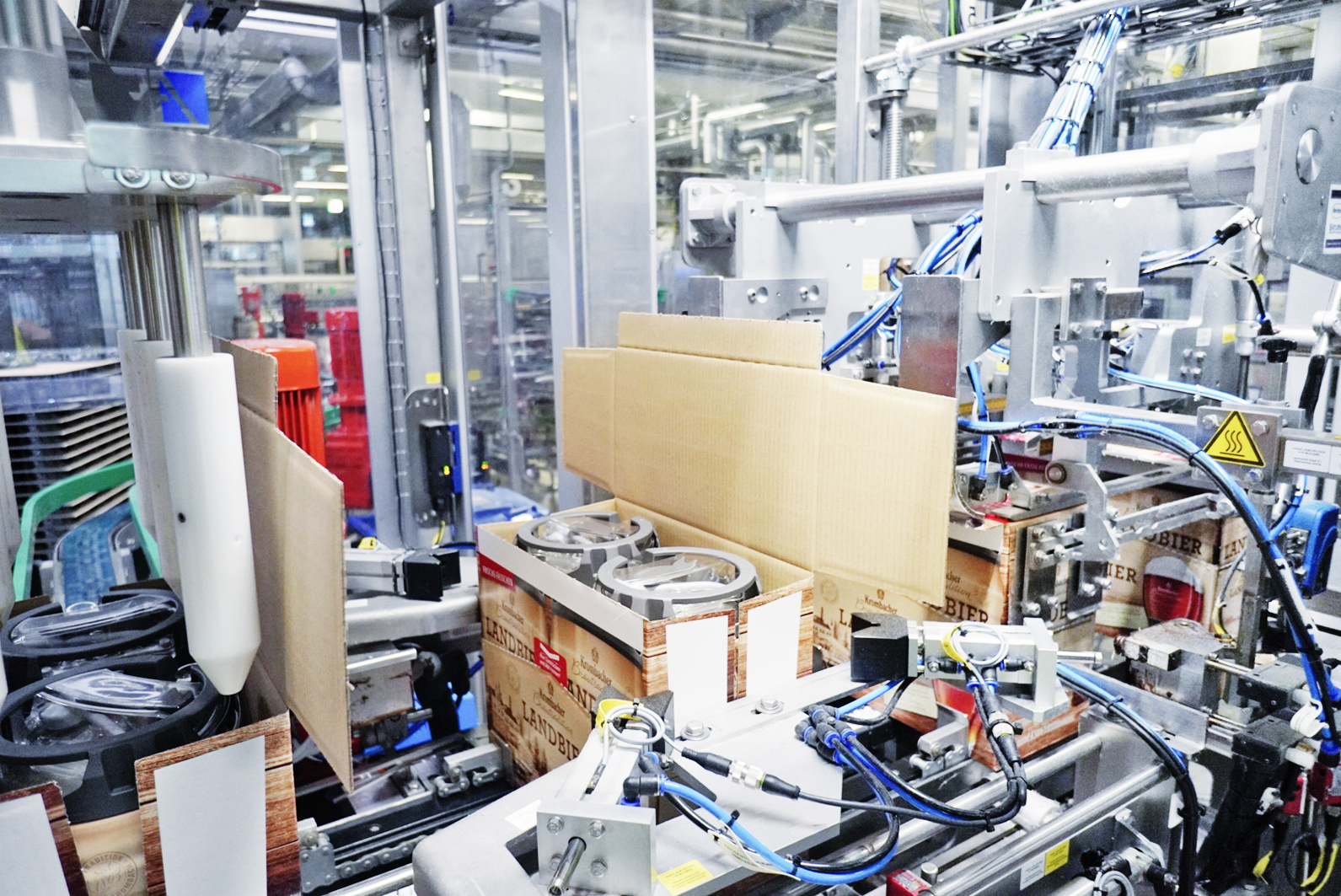

Clearly in a better position with a wrap-around solution

In the packaging area, Krombacher successfully completed a further investment in a smaller but nevertheless significant segment at the beginning of 2022. A segment that certainly gained popularity during the Covid pandemic and the related shutdown of the hospitality sector is the 5-litre party keg - for serving draught beer at home. Here Krombacher distinguishes between the party keg for “Bavarian-type” keg tapping and the fresh keg, which also has an integrated CO2 dispensing unit.

...in combination with a wrap-around packer.

...in combination with a wrap-around packer.

“We had an existing plant for both versions - this was a pick-and-place solution comprising a packer, loader and stretcher”, recalls Rainer Bub, operations engineering/project manager at Krombacher. However, the older machines were getting on in years. They were therefore requiring a lot of maintenance, spare parts were becoming difficult to acquire and the machines were susceptible to faults, leading to a decline in the overall efficiency of the filling system. Oliver Mette, head of the plant development department goes on to explain: “The old plant was therefore practically running around the clock, seven days a week, in order to cope with the demand.“ It was also becoming increasingly difficult to meet the rising requirements in connection with occupational safety on the machine side. All of this combined led to Krombacher looking for a new solution. The question was: What is technically feasible in the available space?” And this space was equal to that of the old plant - there was no scope whatsoever. “This is where we were clearly better off with a wrap-around solution than with a set packer. It was literally a matter of centimetres,” says Bub.

The new line is designed for a maximum output of 1,320 cans equal to 660 wrap-arounds per hour.

The new line is designed for a maximum output of 1,320 cans equal to 660 wrap-arounds per hour.

Mette explains further: “In the old cases the top and bottom sides were sealed with adhesive tape. We can now do without this tape completely because the new wrap-around packaging is glued using hot melt glue. We can also influence the stability of the packaging through the design of the glue dots.“ An important aspect, considering the packs contain two kegs each and weigh over ten kilogrammes. A positive additional effect is that the new packaging can be opened via the perforation without requiring the use of any tool.

Compact combination unit comprising packer, loader and stretcher

Krombacher decided in favour of installing a loader of the type Unipal 108, with low-floor pallet conveyor, in combination with an A+F ModuLine for the wrap-around processing of two formats. For one simple reason: “No other machine manufacturer was able to offer us a combination unit of packer, loader and stretcher of this quality for the given space“, Bub concludes. In addition, according to Mette, there was the much simpler interface clarification: “We had just one contact partner for the overall solution.” The scope of the contract also included the conveyor line required for the connection to the keg filler, the control as well as the integration of the pallet securing. The overall package, comprising keg packing and palletising, was completed on a turnkey basis.

The new plant is designed for a maximum output of 1,320 party kegs that is 660 wrap-arounds per hour. As a comparison: the old plant had an output of 600 party kegs per hour at best. In a nutshell, the challenge was to at least double the hourly output on the same site – while of course complying with the latest ergonomic and occupational specifications. “This output is not currently called for because at 620 kegs per hour we are running at roughly the maximum output of the filler. But we are equipped and ready for future growth”, Mette explains.

A 90° selective turning station integrated in the infeed of the loader aligns the wrap-arounds into a row according to the desired layer pattern.

A 90° selective turning station integrated in the infeed of the loader aligns the wrap-arounds into a row according to the desired layer pattern.

Layer formation directly in the loader head

The frequently mentioned, extremely tight space conditions were particularly challenging. For this reason, also the loader of column-type design and the low-floor pallet conveyor with a height of just over ten centimetres were chosen. Another important factor regarding optimal use of the available space was the 90° selective turning station of A+F. This makes it possible to omit the normally installed layer table, meaning a decisive gain in compactness. In this way, the customer was able to gain major advantages, such as amply dimensioned working areas and excellent accessibility.

This turning station, integrated in the infeed of the loader, aligns the wrap-arounds in a row according to the desired layer pattern. The respective row is then fed to the loader head via a row pusher until the layer pattern has been formed completely. The actual layer formation thus takes place directly in the roller griper head. The completed layers are then placed on the pallet until the pallet has a total of 60 cases, or 120 party kegs. In the case of export pallets there are actually 72 cases. The operation of the newly developed universal roller gripper head is particularly gentle on the product. This gripper head also takes over the pallet and layer pad handling. The loaded pallet is then secured using a stretch wrapper and transported away.

“An excellent example of what can be achieved thanks to the synergies that have been created“

To solve this intricate task a great deal of customisation was therefore needed based on the proven machine technology of two sister companies. “This is an excellent example of what can be achieved thanks to the synergies that have been created. Neither of the two companies could have accomplished this unprecedented feat on their own“, Bub points out. The plant has been running since the end of the first quarter of 2022. Between the dismantling stage and the commissioning there was a period of just ten days. “An important aspect,” says Metter, “was that the commissioning engineer was able to cover both the mechanics and automation here at our construction site.“ The commissioning was followed up with support in the production over fourteen days. “We went straight into three-shift operation during this period. BMS and A+F accompanied this phase in two shifts and we were thus able to reach full performance quickly,” says Bub.

By means of a row pusher, the respective row is fed into the loading head until the layer pattern is completely formed. This means that there is no need for a layer table, which is a decisive plus in terms of compactness.

By means of a row pusher, the respective row is fed into the loading head until the layer pattern is completely formed. This means that there is no need for a layer table, which is a decisive plus in terms of compactness.

And does the experience gathered in practice meet the expectations placed in the investment? Bub sums up: “We have accomplished the set goal of significantly reducing susceptibility clearly achieved.“ As a result of this, the overall efficiency of the filling line has been increased as planned. The operating personnel are the same as with the old plant. It was also never the aim to save on personnel, Mette emphasises: “It was all about state-of-the-art instead of old, reliability instead of susceptibility to faults, and ideally that we would not have to go 24/7.“ Krombacher also found the constructive and flexible cooperation very positive. “As customers, we were helped quickly and without red tape, despite the fact that there were still some spontaneous requests for changes,“ Bub recalls. Mette goes on to conclude: “A big praise to the whole project team. We were and are once again very satisfied.”

You want to read more? Click here for the printed version.

Select your language