Services

Decades of experience – Our performance is your success.

Meeting the diversity of customer requirements is an important claim at BMS.

Therefore, comprehensive service is a matter of course for us. We are ready for action whenever you need our services.

Line training and handling

The most important thing when operating a line is line efficiency. Disturbances and downtimes must be avoided. We train the operators.

Your adventages

- Analysis of the line processes

- Increase in line performance/efficiency

- Cost reduction through optimized processes

- Advice for increase in performance of individual machines (e.g. poor empties)

- Trained staff - employee satisfaction is increased

BMS 24/7 with ticket system

- Including escalation in the event of a plant shutdown via text message to Head of Service

Our policy

- In the event of a plant shutdown the tickets are handled with the highest priority

- Also outside business hours, whenever possible

- BMS service engineers put their heart into delivering intelligent solutions

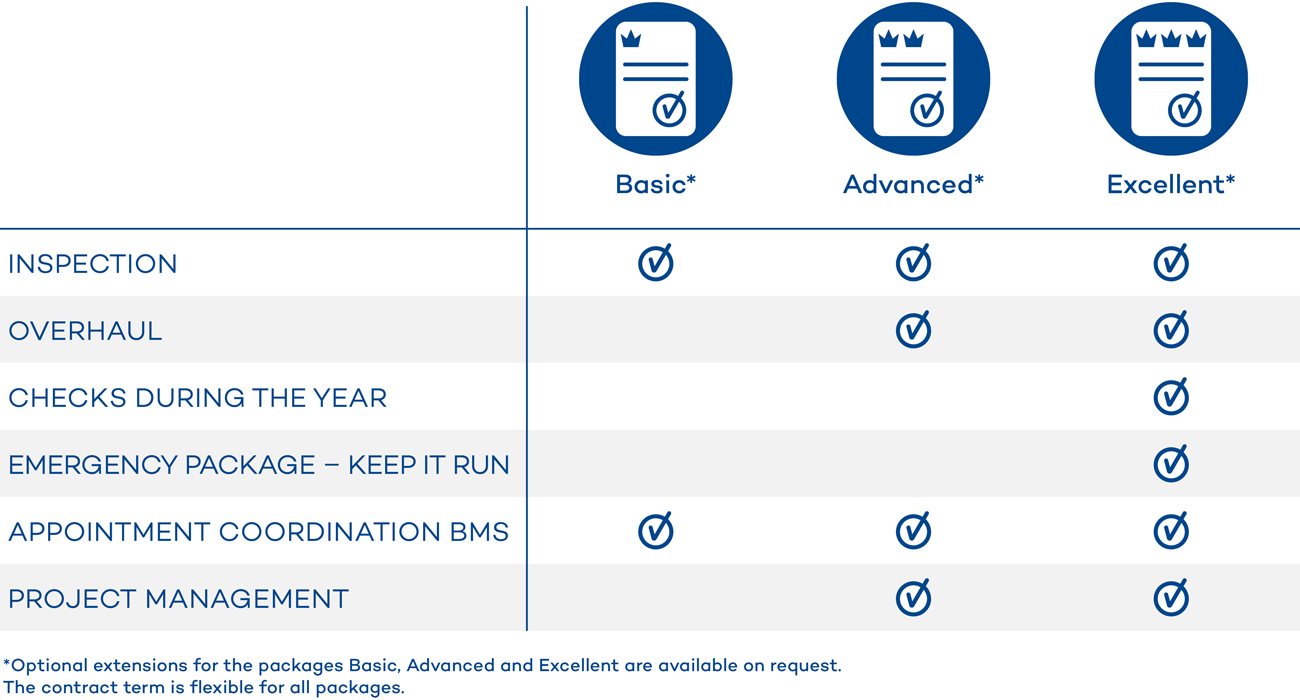

Service Level Agreements

Through the BMS maintenance models, we offer our customers optimal support for the care and maintenance of their BMS machines and systems. A professional execution of inspections and overhauls is crucial to ensure the reliability and efficiency of their BMS machines and plants. In order to meet the specific requirements of our customers, it is possible to flexibly add further options to the Basic, Advanced and Excellent packages.

We will be happy to advise you personally on customised maintenance contracts: This email address is being protected from spambots. You need JavaScript enabled to view it.

Overview

Basic

- Annual inspection incl. report with spare parts recommendation

- Inspection on the basis of the 3D model incl. digital recording of open points

- Appointment coordination by the customer BMS Appointment allocation

Optional

- Man days with individual focus

- Emergency package - Keep it Run

- Line training and handling

Advanced

- Annual inspection incl. report with spare parts recommendation

- Inspection based on the 3D model including digital recording of open points

- Including services, spare parts and final operator training

- Including project management

- Appointment coordination by BMS

- Proactive appointment allocation by BMS

Optional

- Man days with individual focus

- Emergency package - Keep it Run

- Line training and handling

Excellent

- BMS Jump-On process: preparatory inspection and overhaul

- Annual inspection including performance analysis and report with spare parts recommendation

- Inspection based on 3D model including digital recording of open points

- Including services, material and final review

- Including intra-year inspection of the system for performance and efficiency

- Including Keep it Run - emergency package

- Including project management

- Appointment coordination by BMS

- Proactive appointment allocation by BMS

Optional

- Man days with individual focus

- Line training and handling

Select your language