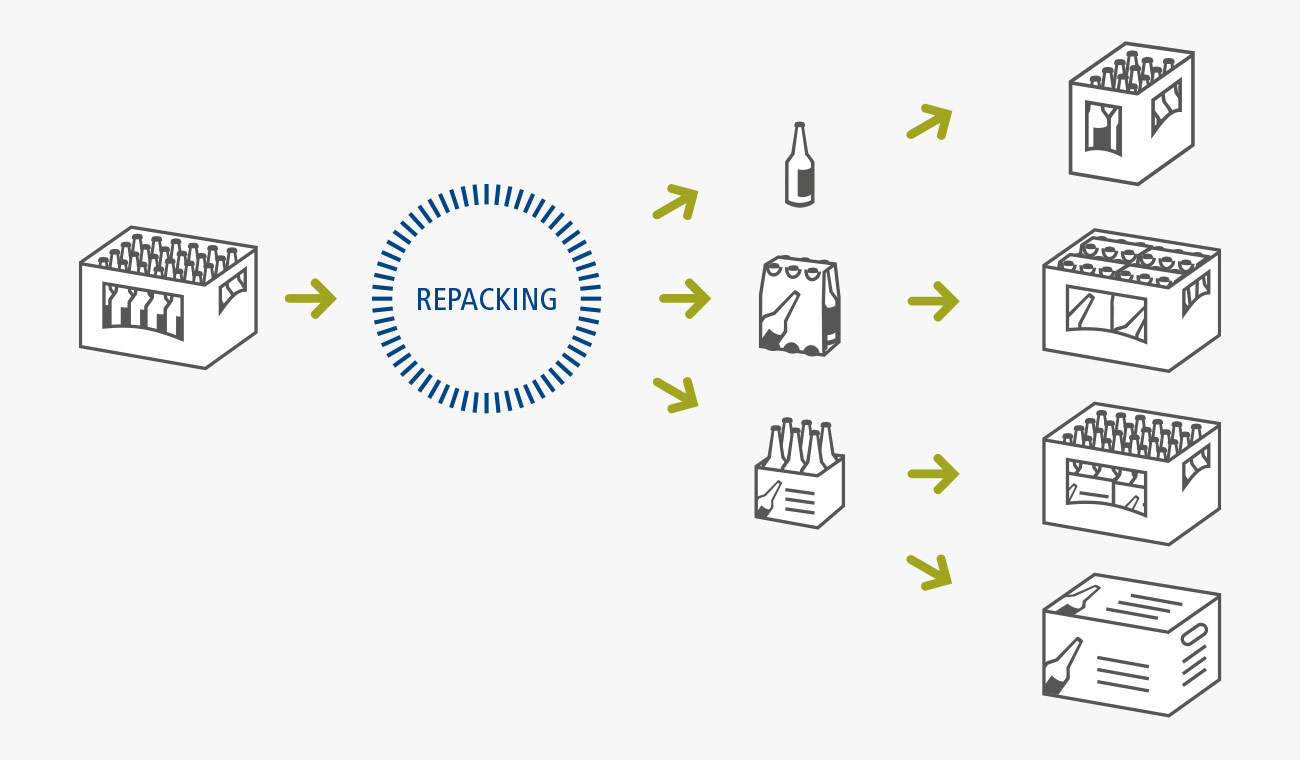

Repacking systems

Efficient handling of all bottle and pack types

Individual bottle and pack shapes, different pack sizes and smaller and more varied packing units are becoming more and more common in the beverage industry due to increasing individualised consumer demands and the growing volume of exports.

Efficiency in the filling line is essential

To ensure efficient production and filling, without requiring additional retooling times to change the format, it is essential for bottles to be packed into standard packs. For this reason, it is only logical to relocate the repacking from the production to logistics. The appropriate repacking of standard packs into individual packs demands both a variety of options and capacity.

With our 30 years of experience in packing technology we are your competent partner when it comes to individual, tailor-made repacking systems – whether for a semi-automatic solution or a fully automated solution, with or without palletising. Get in touch with us.

Bottle logistics: innovative repacking concepts from BMS

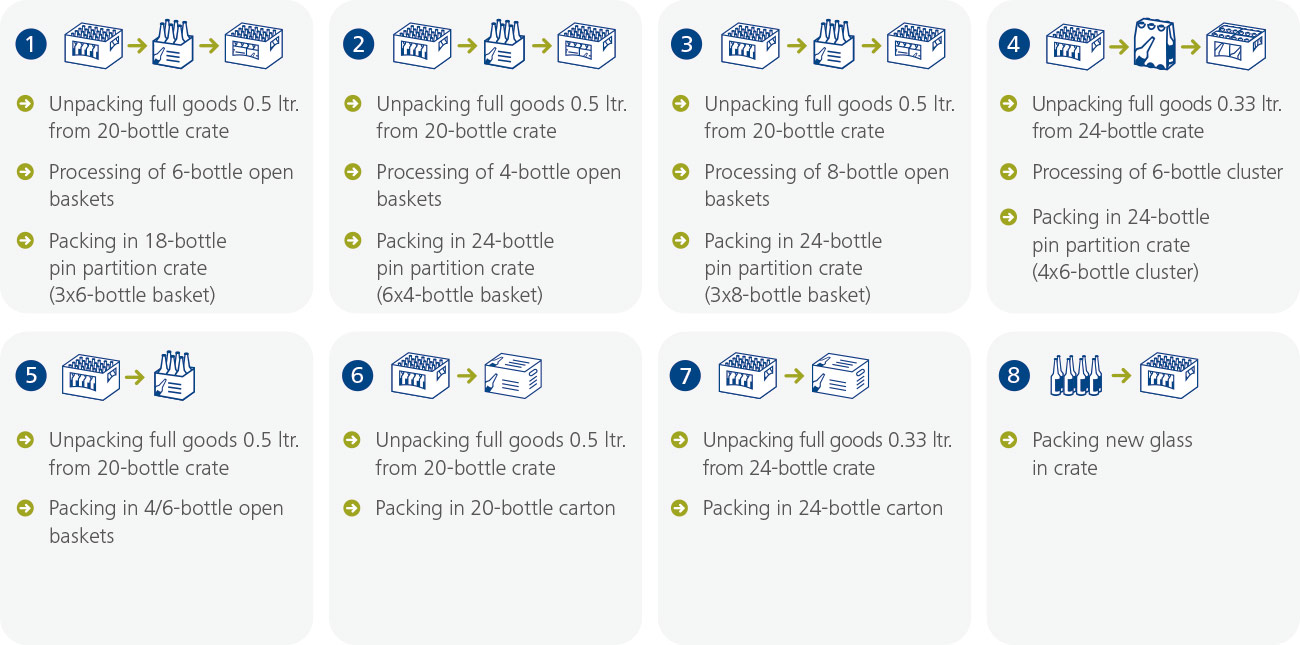

Semi-automatic solution:

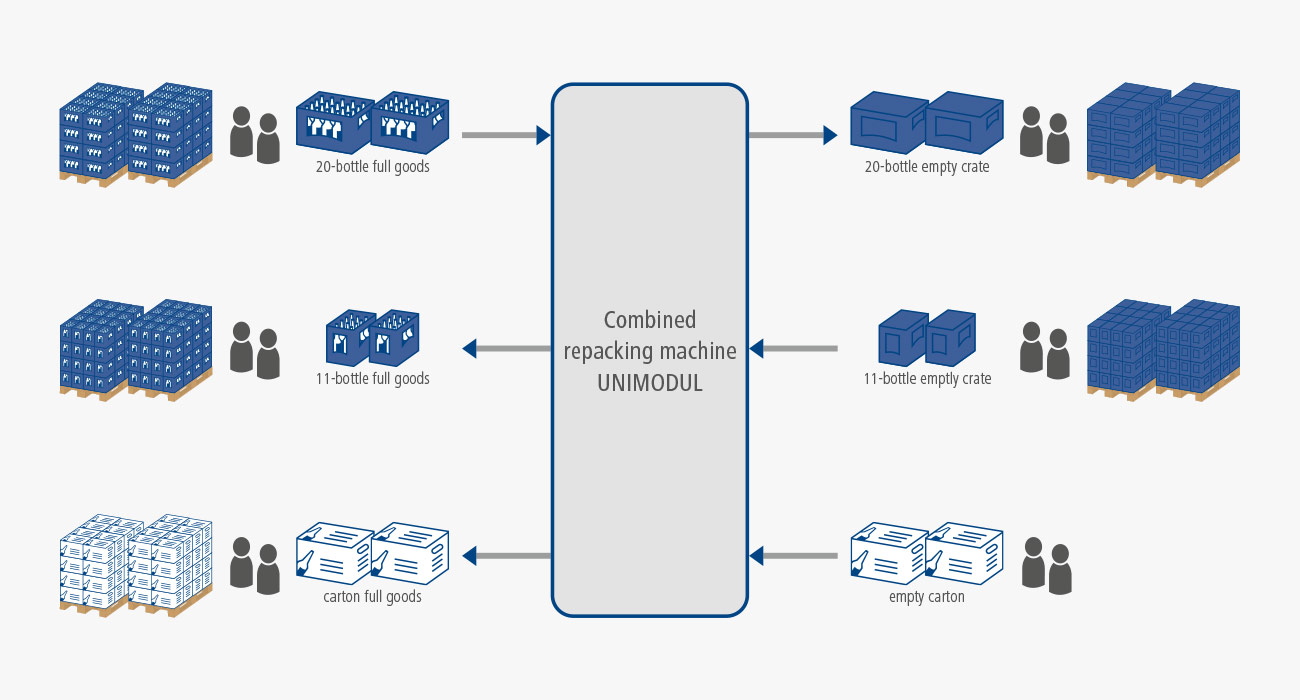

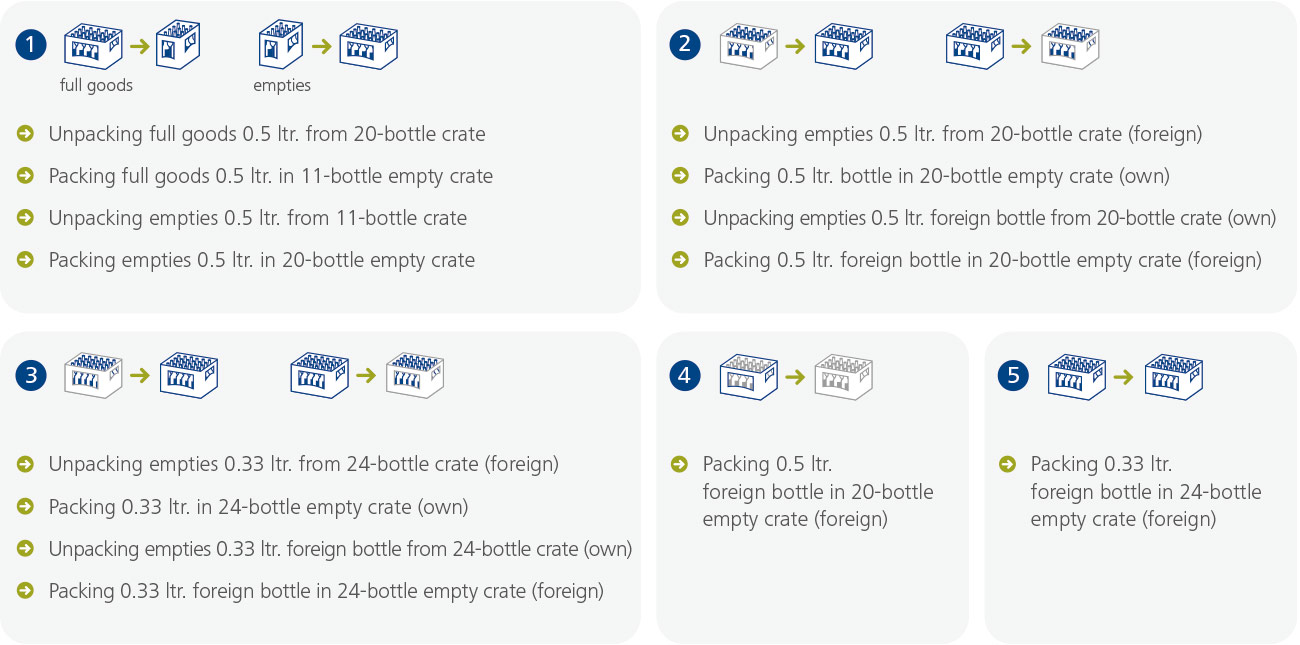

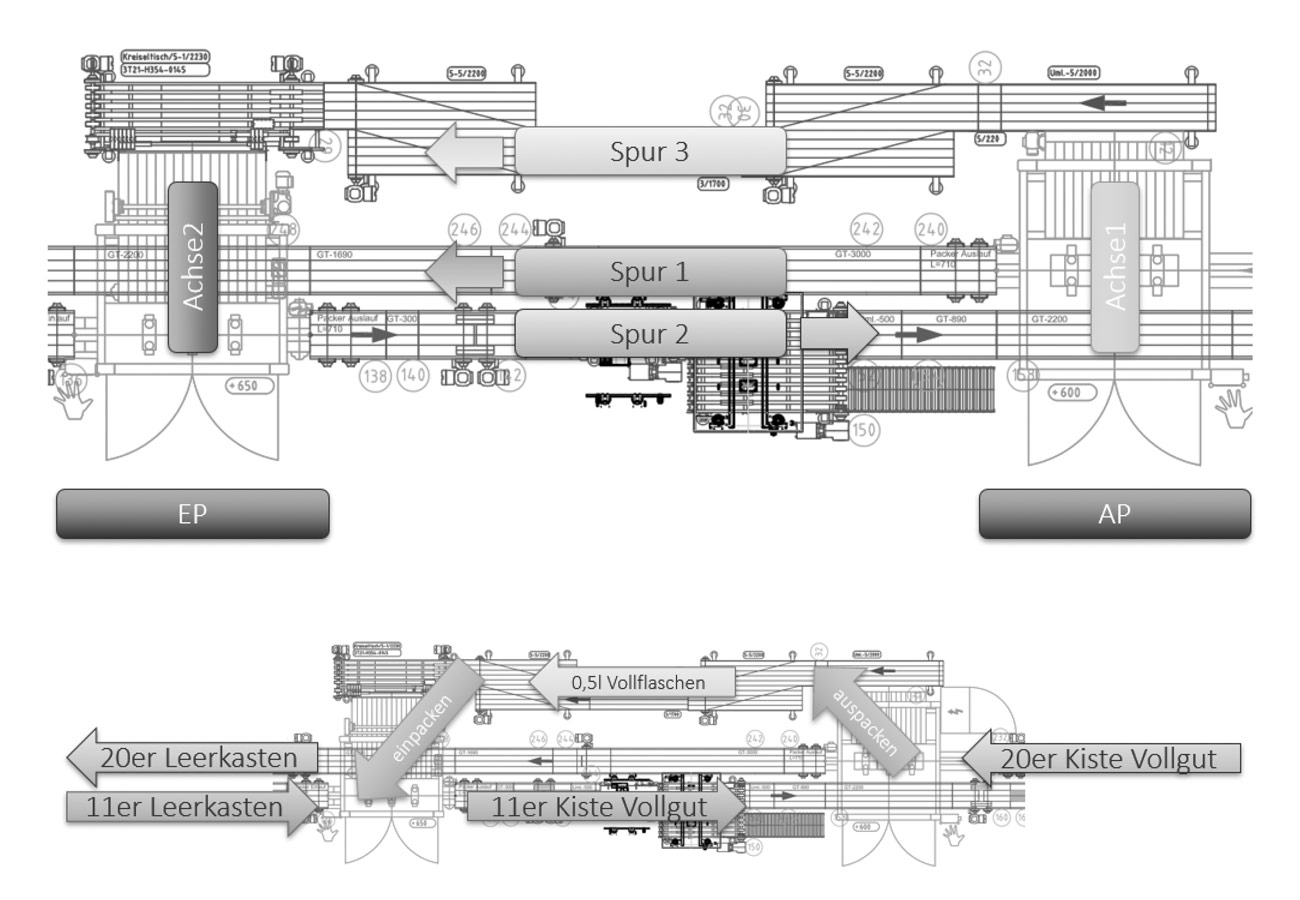

Combined repacking machine BMS UNIMODUL without palletising

Plant output 6,000 bottles/h with 8 repacking programmes

Flow chart of a combined repacking machine BMS UNIMODUL without palletising

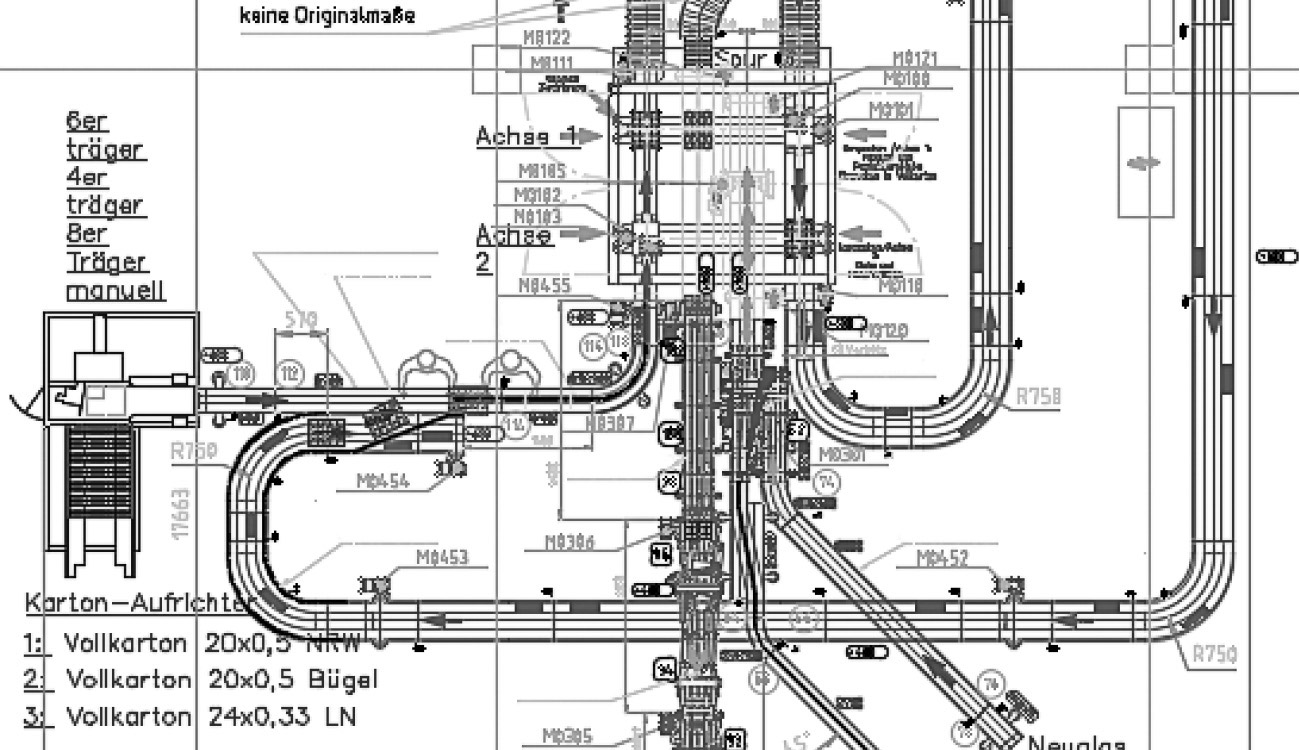

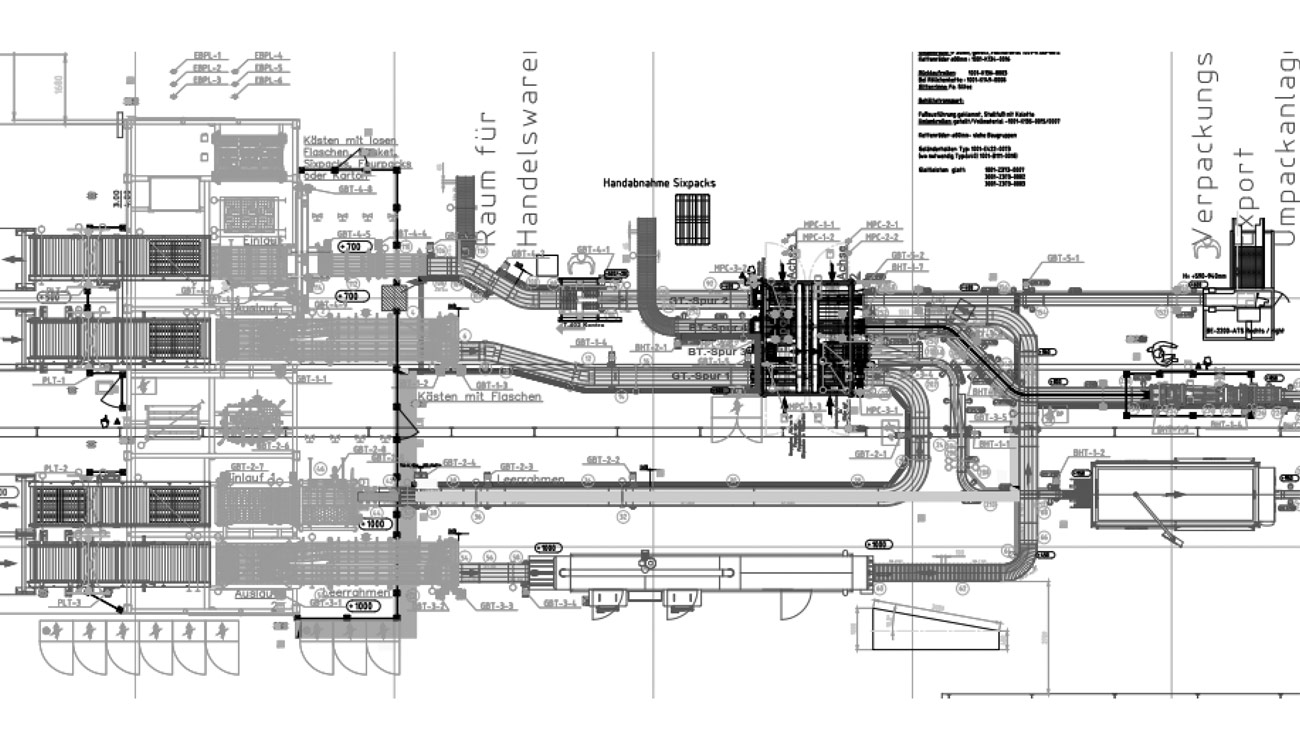

Plant layout

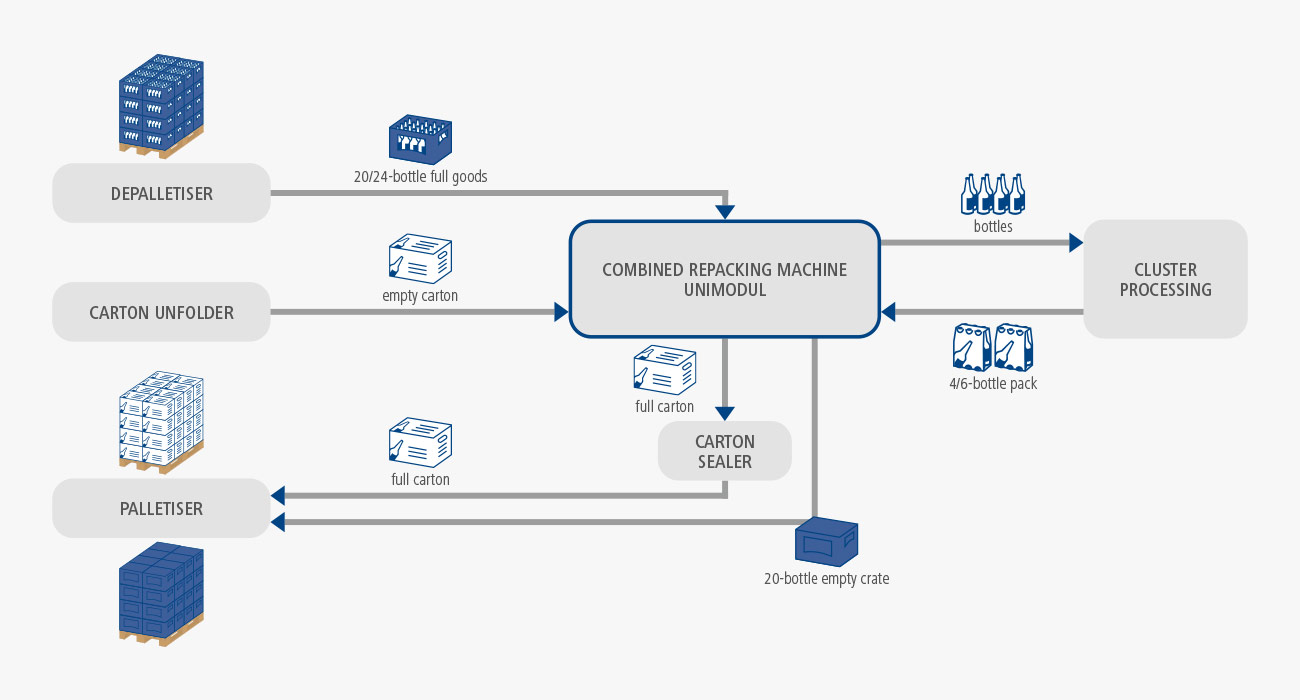

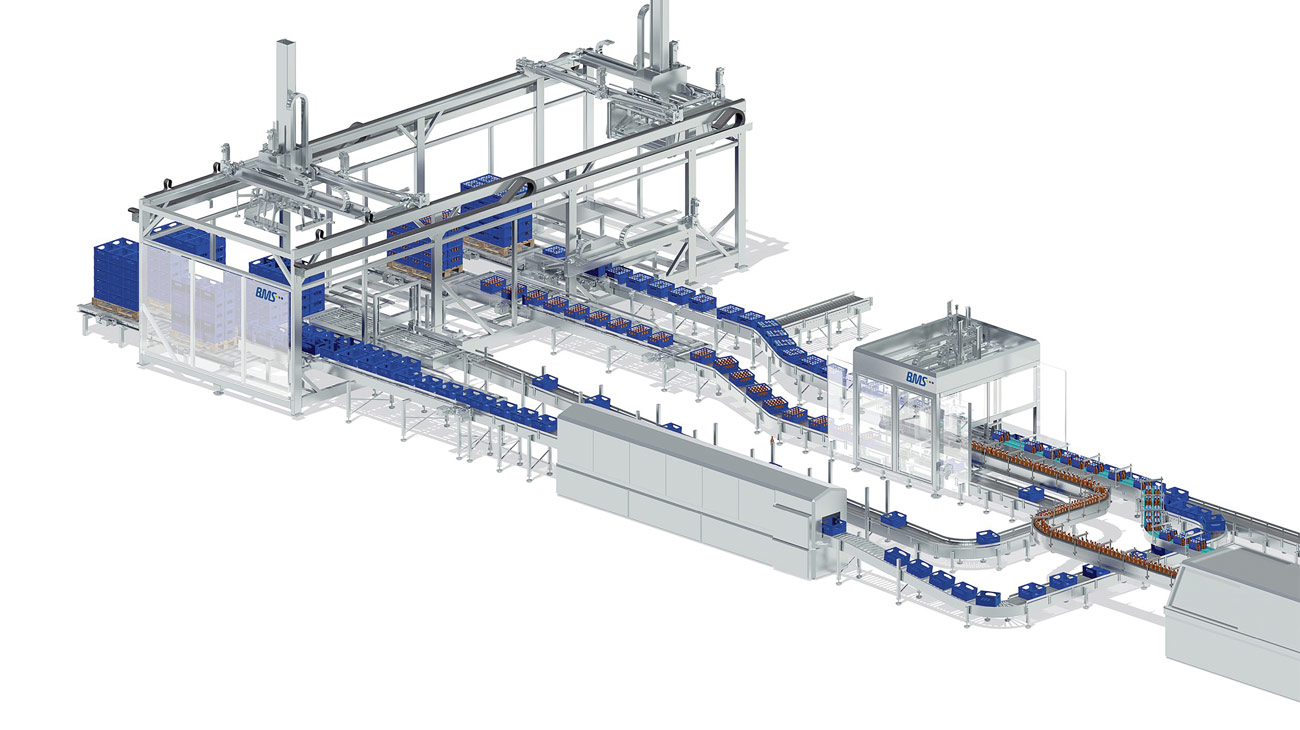

Fully automated solution:

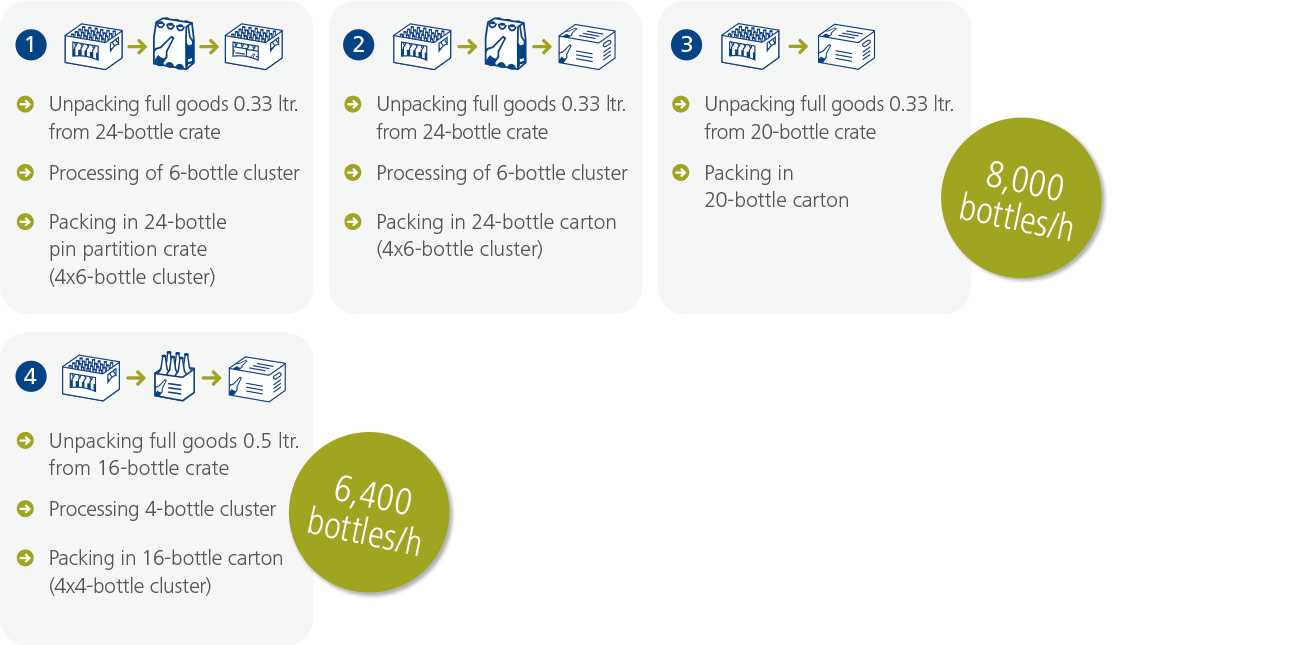

Combined repacking machine with palletising

4 repacking programmes

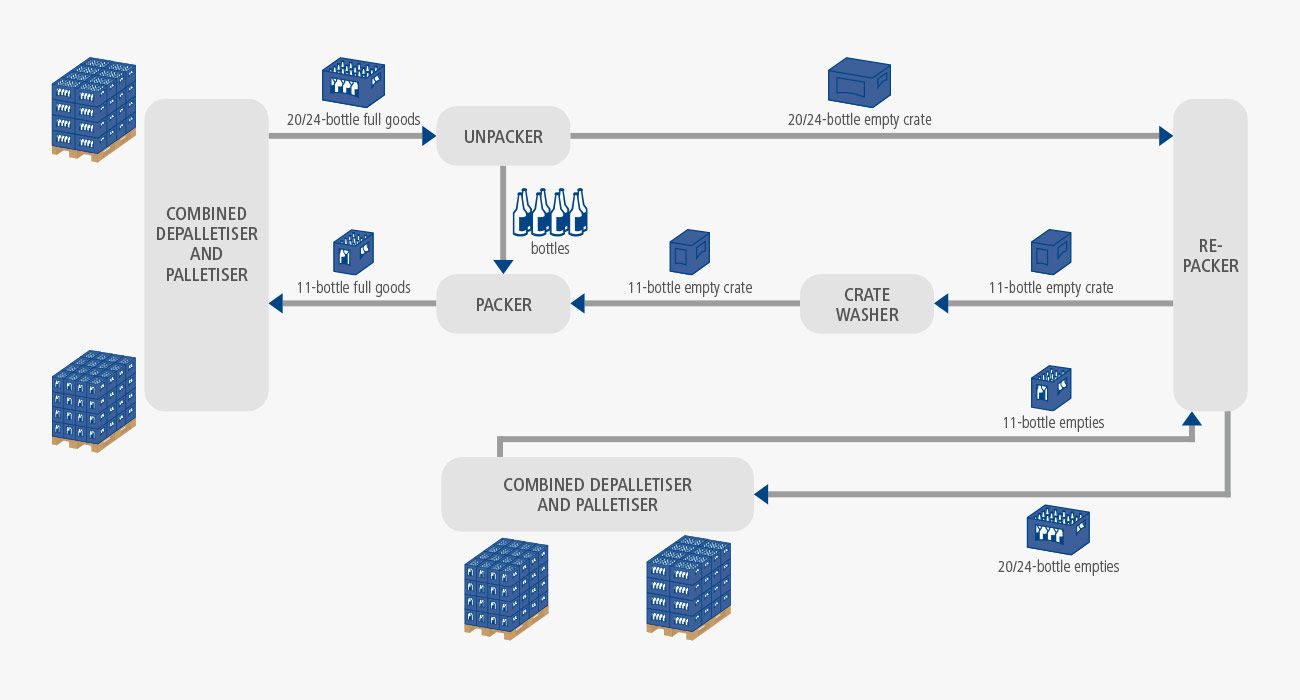

Flow chart of a combined repacking machine with palletising

Plant layout

Fully automated solution: packer, unpacker and repacker with palletising

Plant output capacity 20,000 bottles/h (with repacking programme 1) and 24,000 bottles/h (with repacking programmes 2-5)

Flow chart of a combined repacking system with packer, unpacker and repacker with palletising

Plant layout

Where creativity and flexibility in plant manufacturing stand out:

Repacking into carton, repacker at the Bavarian State Brewery Weihenstephan

Repacking of bottles into open basket and carton, repacker at the Bavarian State Brewery Weihenstephan

Repacking of clip-lock bottles into carton, repacker at the Flensburger Brewery

Repacking of six-packs into carton or crate, repacker at the Flensburger Brewery

BMS Systems and Plants

Sorting systems

For correctly sorted, unmixed empties – Logistics under one roof

Individual bottle and pack shapes and different pack sizes are becoming more and more common in the beverage industry. The share of foreign glass is increasing. This causes a high level of sorting effort at every filling plant, at beverage wholesalers, at every retailer and in every distribution centre. Correctly sorted, unmixed empties are however essential for a high level of plant efficiency in the filling line.

Efficiency in the filling line is essential

To ensure maximum efficiency in production and filling the supply of unmixed empties is paramount. For this reason, sorting is carried out upstream of the filling line.

Depending on the share of foreign bottles and the mix of different types in own or foreign packs, we can design tailor-made sorting plants that perfectly match your specific requirements - whether for a manual, semi-automatic or a fully automated system.Get in touch with us.

Decades of experience in packing technology and our highly trained, innovative engineers guarantee that you will benefit from the best mechanical engineering, functionality and performance in this application as well.

Sorting solutions –

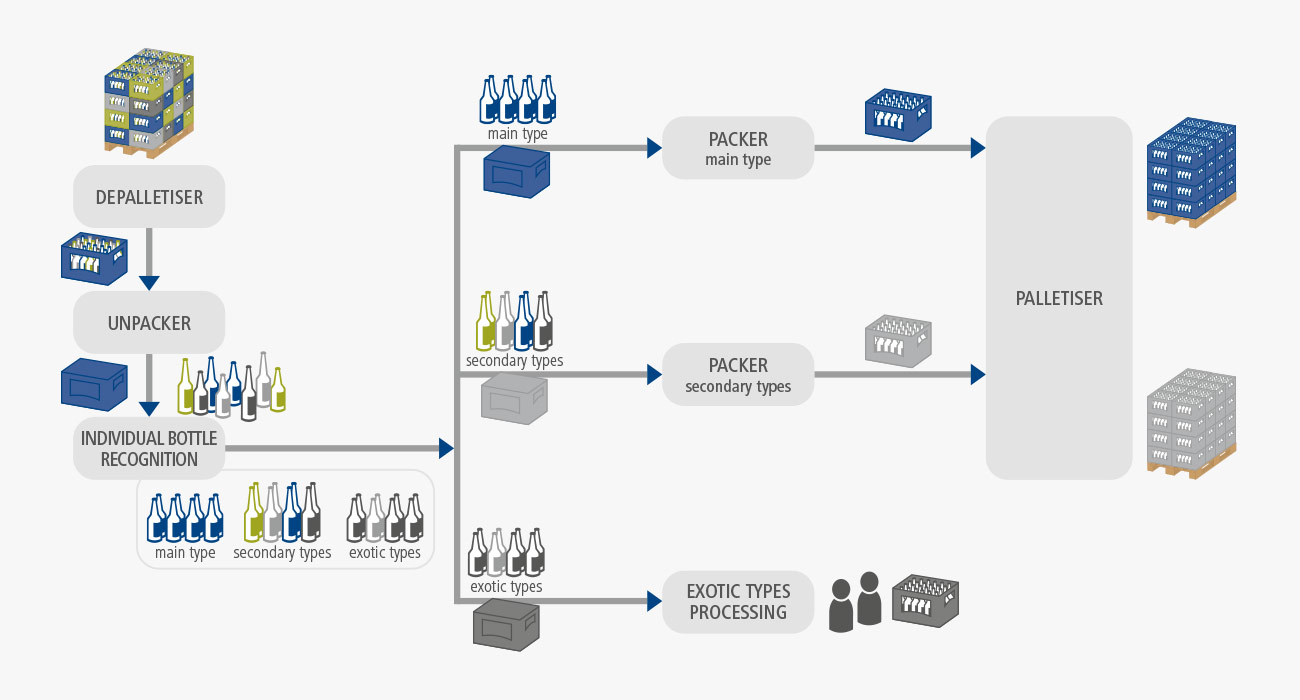

Sorting through individual bottle recognition

Flow chart

Sorting solutions –

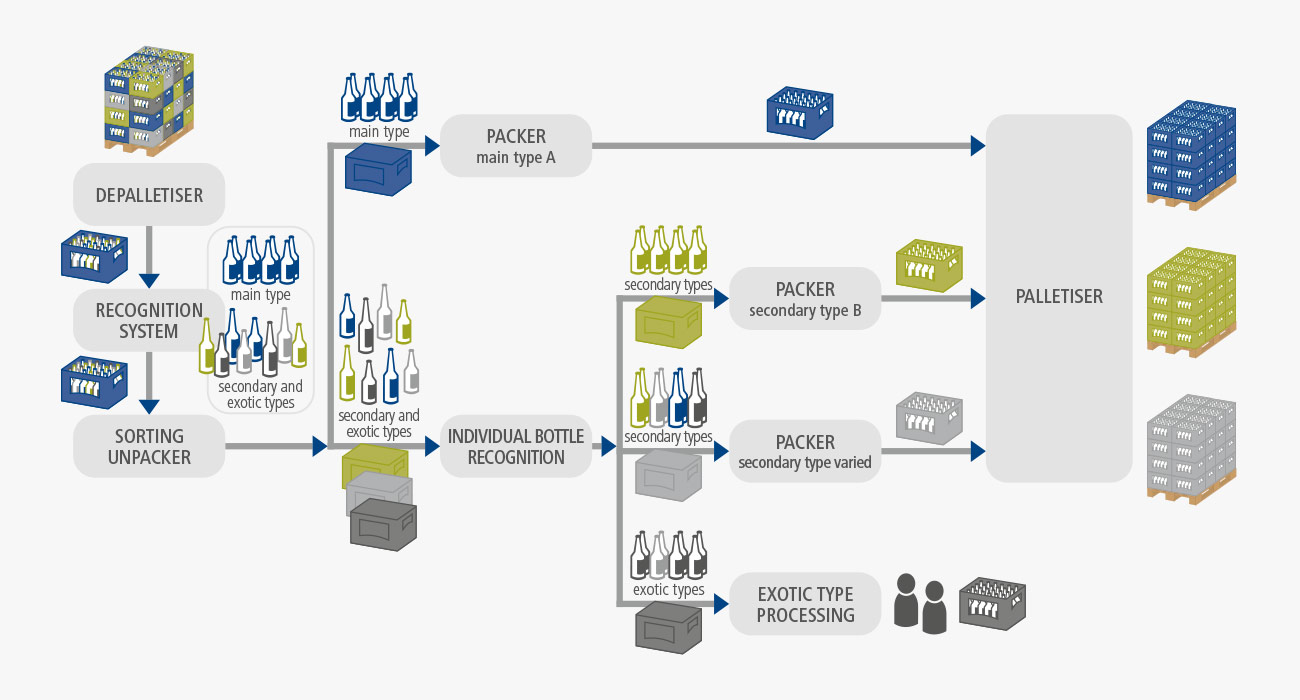

Combination of bottle sorting and crate sorting

Flow chart

Sorting solutions –

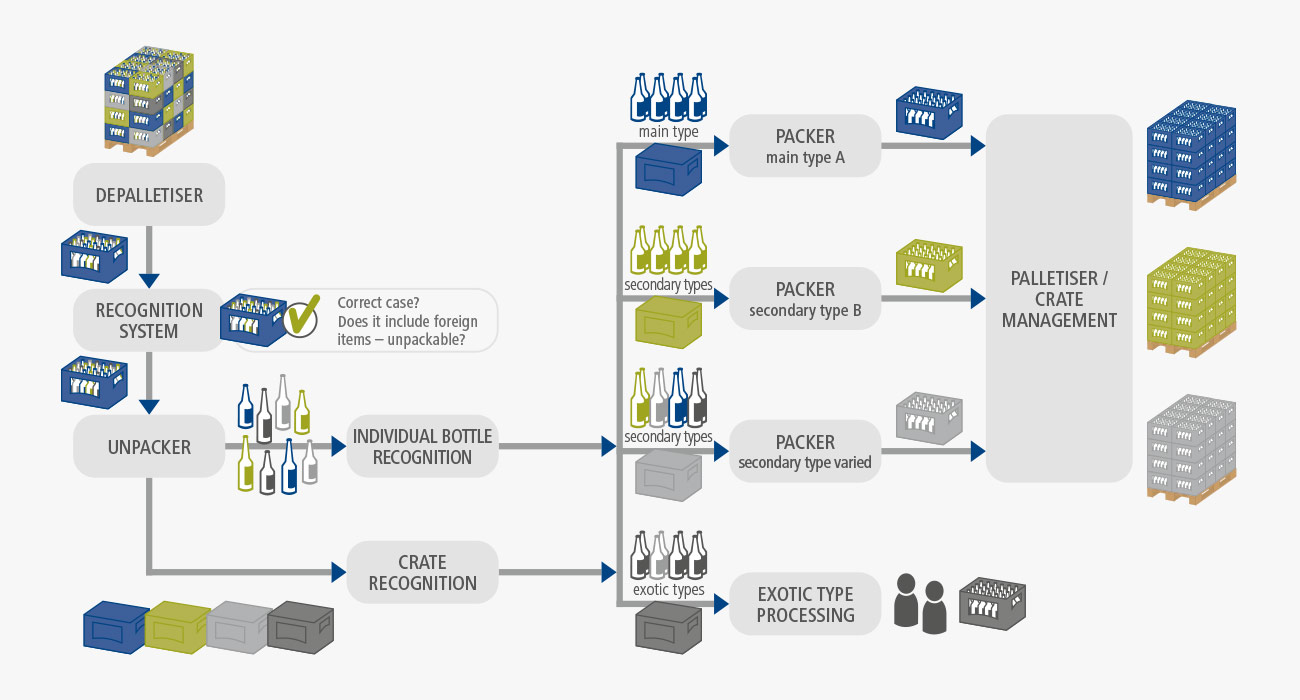

Combination of bottle sorting and crate sorting

Flow chart

BMS Systems and Plants

Systems – BMS dry part for filling lines

Customised design - planned and implemented from start to finish

Are you planning an efficient dry part in a filling line under challenging structural conditions? A good reason to get in touch with us!

Development, manufacturing, delivery, installation, commissioning – we do it all at BMS. With our flexible and creative approach we have moved on over the past 10 years to become system specialists for demanding projects in the filling and logistics sector.

Thanks to our extensive know-how and expertise in plant design - gained from many implemented projects in the filling and logistics sector - we are able to plan and develop tailored solutions for the dry part of your filling line. We combine our experience as plant manufacturer and your experience in plant operations with a systematic approach, commitment and ideas to provide individual, tailor-made dry part concepts that are both effective and economic.

Your defined standard is our standard. We take your individual wishes into account in a flexible manner and incorporate these in our planning process.

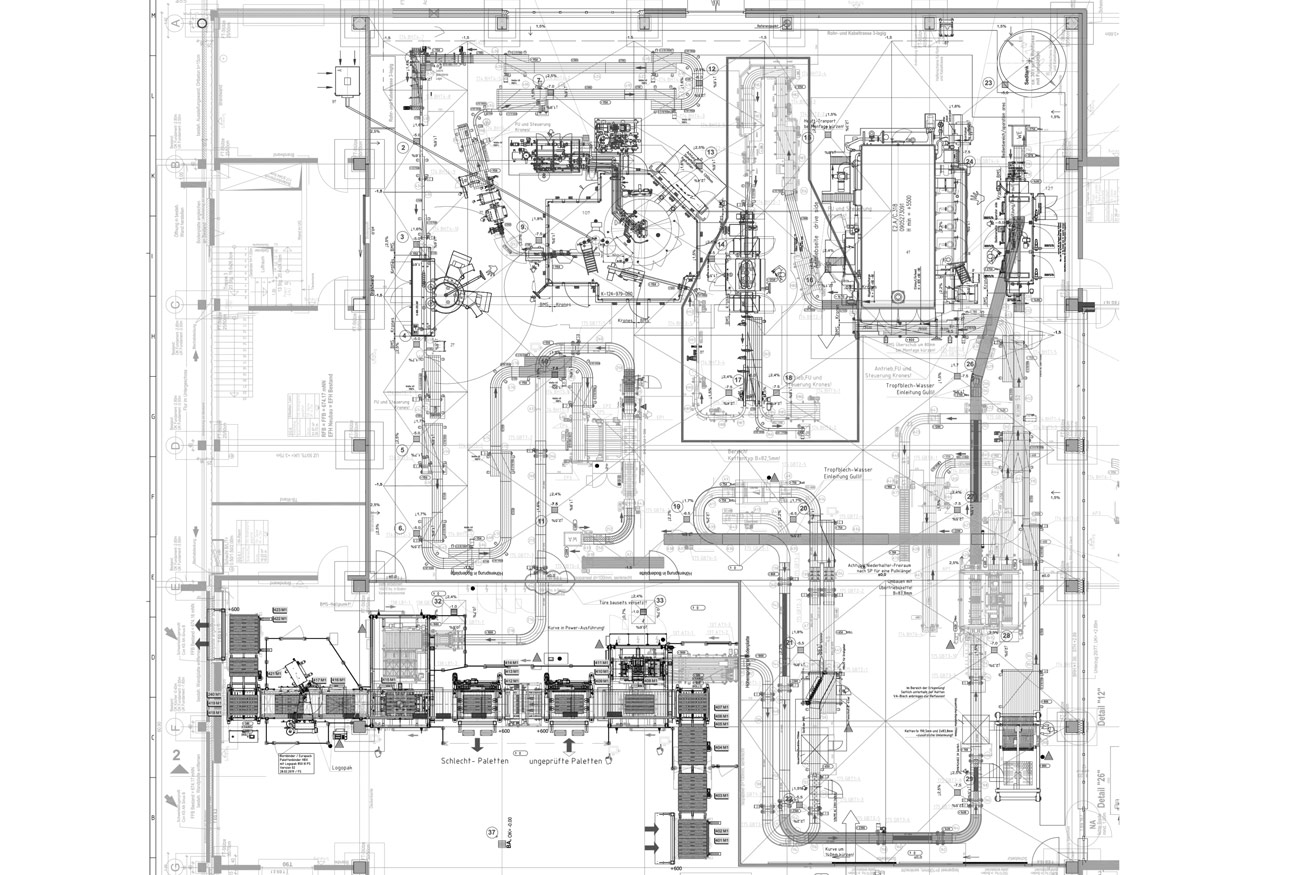

BMS dry part for filling lines

with integrated sorting

Plant layout

Where creativity and flexibility in plant manufacturing stand out:

Pack conveyor system, dry part at Braucommune Freistadt

Packer and unpacker, dry part at Braucommune Freistadt

Infeed and packer, dry part at Braucommune Freistadt

Pack conveyor system, dry part at Arcobräu Gräfliches Brauhaus

Packer and unpacker, dry part at Mineralbrunnen Krumbach

Container conveyor system and pack conveyor system, dry part at Mineralbrunnen Krumbach