3D Puzzle

Demanding spatial conditions pose major challenges for the new palletising station at the Wittmann brewery – these have now been solved

Brauerei C. Wittmann OHG, Landshut, is a medium-sized private brewery that has been family-owned for five generations. It originated from the breweries “Zum Heiß“ and “Zum Dräxlmair“. The history of the brewery „Zum Dräxlmair“ can be traced back to the year 1616. In 1905/06, the brewery - which was at that time still located in the centre of Landshut - moved to the outskirts of the city, to an area which is now in the centre of the city’s Achdorf district. The administrative office had to be separated and is now located in the historic Etzdorf Palais in the Ländgasse.

The Wittmann brewery is a specialty brewery and supplies customers within a radius of approximately 50 to 70 kilometres around the city of Landshut. It is a classic full-range supplier of top and bottom fermented beers and also non-alcoholic beverages. The Wittmann brewery boasts a tradition of very high standards regarding the quality of the raw materials used and the brewing technology. This active philosophy has led to many DLG (German Agricultural Society) awards such as the “Preis der Besten” and 70 further gold awards.

“The next logical step we had to take“

Another essential element of this success is the consistent investment in environmentally friendly and quality-oriented machine technology. The Wittmann brewery is currently replacing its entire filling line in a project that involves several phases. The first step was the implementation of two state-of-the-art portal-type packers in the existing line. The new construction of the palletising station then commenced in 2023. Florian Drißl, first brewmaster at Wittmann, looks back: “The existing palletising system dated back to the late 1970s. The spare part and maintenance situation was therefore proving difficult. It was simply the next logical step we had to take in the process of renewing the bottling line.“

We had to make do with the spatial conditions of the old plant

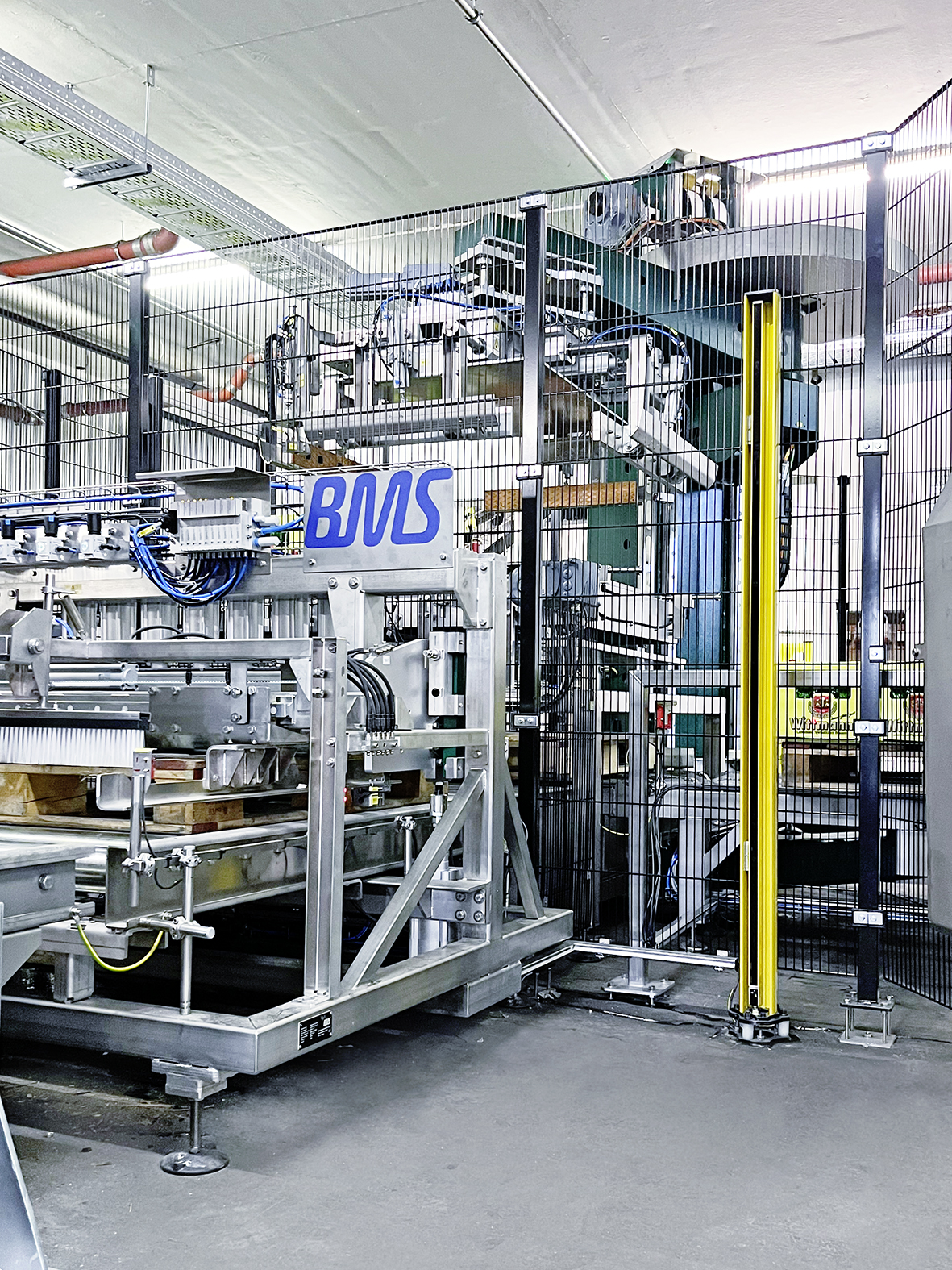

For the implementation of the project the brewery had set very clear requirements: the palletising station should be able to feed the future filler with 30,000 bottles per hour with ease, it should offer maximum operational reliability, be fully automated using state-of-the-art technology and include a crate turning station and pallet inspection – all of this within the same spatial conditions of the old plant. There was a further task that had to be solved concerning the pallets. “As a medium-sized company with our own fleet of vehicles we still use the brewery pallet which is more attractive in many respects. However, we also have to deliver smaller batches on Euro pallets. In the old plant these were loaded manually. The new system should be able to do this automatically“, Drißl explains.

3.80 metres ceiling height, limited floorspace, increased functions – the planning of the new palletising station of the Wittmann brewery was extremely demanding.

3.80 metres ceiling height, limited floorspace, increased functions – the planning of the new palletising station of the Wittmann brewery was extremely demanding.

A floor to ceiling height of just 3.80 metres

A key challenge in the planning and implementation of the project was posed by the spatial conditions. This was primarily due to the low ceiling height of just 3.80 metres. This meant that only column-type palletisers could be used. But even these were too high as standard version. It was also necessary to include the required turning station and the pallet inspection in the given floorspace. Last but not least, interfaces had to be prepared for the modified conveyor system of the new filling plant. “With so many restrictions and requirements, some bidders dropped out of the tender process straight away. They were either not confident enough with their portfolio or did not want to undertake the amount of additional work required for this level of customisation”, Drißl remarks.

Modified design reduces the column height

This 3D puzzle of room height and floorspace was solved using a special version of the column-type palletiser UNIPAL Type 108. To this end, elements such as the drive technology, cable routing or valve terminals, which are normally positioned at the top of the column, are arranged on the side or underneath. In this way, it was possible to reduce the height and install the two palletisers at Wittmann. The reduced height also provides another major advantage: the column-type palletiser can be transported upright on a truck. Brewmaster Drißl sums it all up: “This is better because I don’t have to disassemble the columns, I can leave the gripper head on, for instance. I can also load, unload and integrate them more easily – for us this basically means a reduction of about two to three days for the assembly work.“

A new design made it possible to reduce the height of the columns making the floor-to-ceiling height of 3.80 metres sufficient. The clearance to the ceiling is still minimal.

A new design made it possible to reduce the height of the columns making the floor-to-ceiling height of 3.80 metres sufficient. The clearance to the ceiling is still minimal.

The unloader is designed for an output of 39,000 bottles per hour and the loader for an output of 36,000 bottles per hour. The conveyors, layer tables, control and the pallet control were also supplied. The subsequent integration of a pallet binder as well as interfaces for the future filling line have already been prepared. The entire package, including dismantling, installation, commissioning and training, was handled on a turnkey basis. The Wittmann brewery was responsible for on-site work by others.

Virtual construction site management proves its worth once again

The contract was awarded in May 2023. Assembly in Landshut got underway on 23.01.2024, the first bottles were filled on 12.02.2024. “We had scheduled three weeks for the entire project, including the dismantling and on-site preparation. We kept fully within this time frame“, Drißl explains. The construction site management system LOP 4.0 made a significant contribution to this speedy implementation. LOP 4.0 is a cloud-based construction site management system to which all those participating in the project have access. This digital platform maps the current status with the highest possible transparency during the construction site phase, from the delivery right up to the commissioning. LOP 4.0 is furthermore an open communication and documentation platform. Each project partner can, for example, upload photos or videos, propose next steps or prioritise individual items. This makes sure that the status of all project modules is always up to date and clearly understandable. “We had already gained positive experience with LOP 4.0 in connection with the packers. This simply has the advantage that nothing goes missing, due to the system always being up to date and transparent“, Drißl underscores. And talking about packers: there were also two other side effects in connection with the palletising station. Firstly, these packers can now be accessed via the remote maintenance of the palletising system. And secondly, Drißl explains: “This initial cooperation was performed absolutely smoothly and the machines are running excellently. We were simply confident that the same would be the case with the palletising system, and this has also been confirmed.“

The new plant predominantly processes brewery pallets. Euro pallets can, however, also be fed in in batches during the operation.

The new plant predominantly processes brewery pallets. Euro pallets can, however, also be fed in in batches during the operation.

Euro pallets are simply fed in during the production flow

The entire plant has been proving its worth in every-day operation since the end of March 2024. It processes a 20-bottle module crate, two 24-bottle module crates as well as a 11-bottle lemonade crate which has a special feature: this crate is only roughly half the size of the other crates and therefore has to be rotated for palletising. “This is where, in the old plant, staff were needed to help make sure that the crates did not jam. The new plant takes care of this smoothly and automatically“, Drißl is delighted to say.

In terms of the pallets used, both brewery pallets and Euro pallets can be loaded and unloaded, as required. In the new plant, these can be fed in via the reject pallet magazine at any time “at the touch of a button” and are then ready for palletising. Drißl explains the advantage of this feature: “We don’t have to changeover pallets in the palletising station in order to process a small batch of around 30 Euro pallets. This not only saves us from having to manually stack the full goods, it also saves a changeover time of at least 45 minutes.“ The plant is, however, also already designed to predominantly process Euro pallets, if the market so requires. In this case, the brewery pallets are fed in via the pallet magazine.

A reduced column height also means that the palletiser can be transported upright. This significantly reduces transport, installation and assembly work.

A reduced column height also means that the palletiser can be transported upright. This significantly reduces transport, installation and assembly work.

“Everything agreed has been completely fulfilled“

In a nutshell: The new palletising station of the Wittmann brewery reliably provides the required performance, despite the challenging spatial conditions. The problems with the turning station no longer exist, the pallet inspection offers enhanced safety and the Euro pallets can now be fed in fully automatically during the operation. Brewmaster Drißl is happy to confirm that following the practical experience gathered with the plant: “Everything agreed has been completely fulfilled. We are absolutely satisfied. The palletising station will certainly not discourage possible follow-up projects.“