3D Puzzle

Demanding spatial conditions pose major challenges for the new palletising station at the Wittmann brewery – these have now been solved

Brauerei C. Wittmann OHG, Landshut, is a medium-sized private brewery that has been family-owned for five generations. It originated from the breweries “Zum Heiß“ and “Zum Dräxlmair“. The history of the brewery „Zum Dräxlmair“ can be traced back to the year 1616. In 1905/06, the brewery - which was at that time still located in the centre of Landshut - moved to the outskirts of the city, to an area which is now in the centre of the city’s Achdorf district. The administrative office had to be separated and is now located in the historic Etzdorf Palais in the Ländgasse.

The Wittmann brewery is a specialty brewery and supplies customers within a radius of approximately 50 to 70 kilometres around the city of Landshut. It is a classic full-range supplier of top and bottom fermented beers and also non-alcoholic beverages. The Wittmann brewery boasts a tradition of very high standards regarding the quality of the raw materials used and the brewing technology. This active philosophy has led to many DLG (German Agricultural Society) awards such as the “Preis der Besten” and 70 further gold awards.

“The next logical step we had to take“

Another essential element of this success is the consistent investment in environmentally friendly and quality-oriented machine technology. The Wittmann brewery is currently replacing its entire filling line in a project that involves several phases. The first step was the implementation of two state-of-the-art portal-type packers in the existing line. The new construction of the palletising station then commenced in 2023. Florian Drißl, first brewmaster at Wittmann, looks back: “The existing palletising system dated back to the late 1970s. The spare part and maintenance situation was therefore proving difficult. It was simply the next logical step we had to take in the process of renewing the bottling line.“

We had to make do with the spatial conditions of the old plant

For the implementation of the project the brewery had set very clear requirements: the palletising station should be able to feed the future filler with 30,000 bottles per hour with ease, it should offer maximum operational reliability, be fully automated using state-of-the-art technology and include a crate turning station and pallet inspection – all of this within the same spatial conditions of the old plant. There was a further task that had to be solved concerning the pallets. “As a medium-sized company with our own fleet of vehicles we still use the brewery pallet which is more attractive in many respects. However, we also have to deliver smaller batches on Euro pallets. In the old plant these were loaded manually. The new system should be able to do this automatically“, Drißl explains.

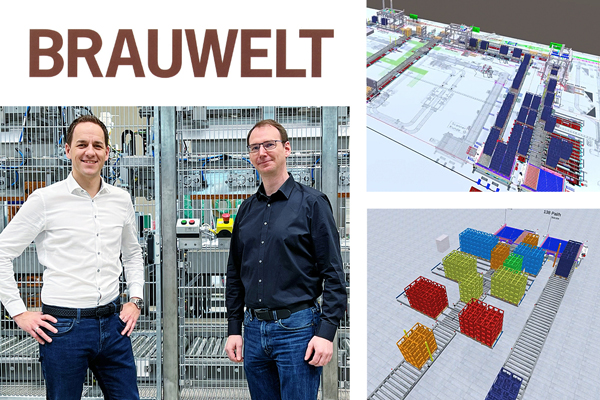

3.80 metres ceiling height, limited floorspace, increased functions – the planning of the new palletising station of the Wittmann brewery was extremely demanding.

3.80 metres ceiling height, limited floorspace, increased functions – the planning of the new palletising station of the Wittmann brewery was extremely demanding.

A floor to ceiling height of just 3.80 metres

A key challenge in the planning and implementation of the project was posed by the spatial conditions. This was primarily due to the low ceiling height of just 3.80 metres. This meant that only column-type palletisers could be used. But even these were too high as standard version. It was also necessary to include the required turning station and the pallet inspection in the given floorspace. Last but not least, interfaces had to be prepared for the modified conveyor system of the new filling plant. “With so many restrictions and requirements, some bidders dropped out of the tender process straight away. They were either not confident enough with their portfolio or did not want to undertake the amount of additional work required for this level of customisation”, Drißl remarks.

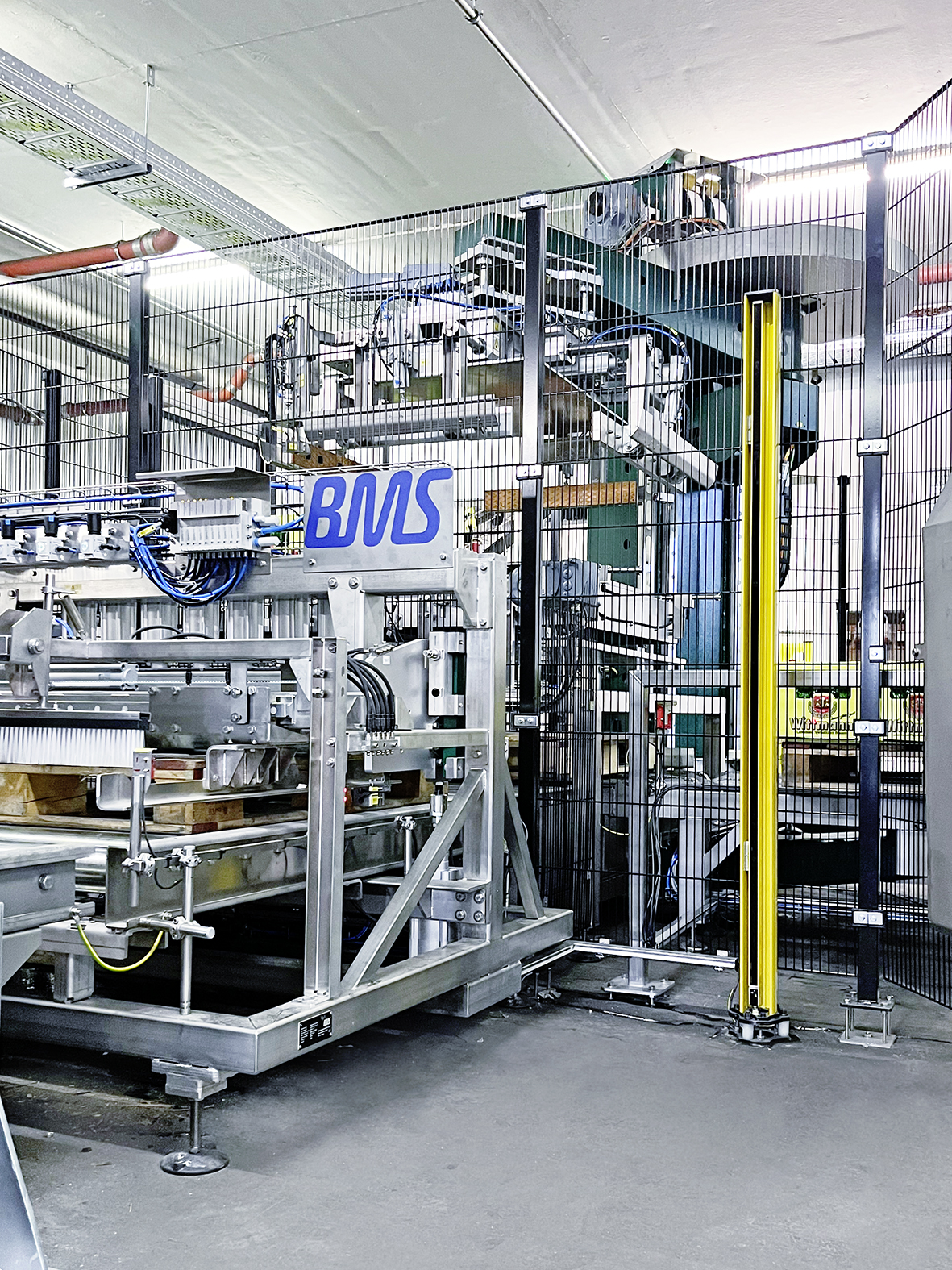

Modified design reduces the column height

This 3D puzzle of room height and floorspace was solved using a special version of the column-type palletiser UNIPAL Type 108. To this end, elements such as the drive technology, cable routing or valve terminals, which are normally positioned at the top of the column, are arranged on the side or underneath. In this way, it was possible to reduce the height and install the two palletisers at Wittmann. The reduced height also provides another major advantage: the column-type palletiser can be transported upright on a truck. Brewmaster Drißl sums it all up: “This is better because I don’t have to disassemble the columns, I can leave the gripper head on, for instance. I can also load, unload and integrate them more easily – for us this basically means a reduction of about two to three days for the assembly work.“

A new design made it possible to reduce the height of the columns making the floor-to-ceiling height of 3.80 metres sufficient. The clearance to the ceiling is still minimal.

A new design made it possible to reduce the height of the columns making the floor-to-ceiling height of 3.80 metres sufficient. The clearance to the ceiling is still minimal.

The unloader is designed for an output of 39,000 bottles per hour and the loader for an output of 36,000 bottles per hour. The conveyors, layer tables, control and the pallet control were also supplied. The subsequent integration of a pallet binder as well as interfaces for the future filling line have already been prepared. The entire package, including dismantling, installation, commissioning and training, was handled on a turnkey basis. The Wittmann brewery was responsible for on-site work by others.

Virtual construction site management proves its worth once again

The contract was awarded in May 2023. Assembly in Landshut got underway on 23.01.2024, the first bottles were filled on 12.02.2024. “We had scheduled three weeks for the entire project, including the dismantling and on-site preparation. We kept fully within this time frame“, Drißl explains. The construction site management system LOP 4.0 made a significant contribution to this speedy implementation. LOP 4.0 is a cloud-based construction site management system to which all those participating in the project have access. This digital platform maps the current status with the highest possible transparency during the construction site phase, from the delivery right up to the commissioning. LOP 4.0 is furthermore an open communication and documentation platform. Each project partner can, for example, upload photos or videos, propose next steps or prioritise individual items. This makes sure that the status of all project modules is always up to date and clearly understandable. “We had already gained positive experience with LOP 4.0 in connection with the packers. This simply has the advantage that nothing goes missing, due to the system always being up to date and transparent“, Drißl underscores. And talking about packers: there were also two other side effects in connection with the palletising station. Firstly, these packers can now be accessed via the remote maintenance of the palletising system. And secondly, Drißl explains: “This initial cooperation was performed absolutely smoothly and the machines are running excellently. We were simply confident that the same would be the case with the palletising system, and this has also been confirmed.“

The new plant predominantly processes brewery pallets. Euro pallets can, however, also be fed in in batches during the operation.

The new plant predominantly processes brewery pallets. Euro pallets can, however, also be fed in in batches during the operation.

Euro pallets are simply fed in during the production flow

The entire plant has been proving its worth in every-day operation since the end of March 2024. It processes a 20-bottle module crate, two 24-bottle module crates as well as a 11-bottle lemonade crate which has a special feature: this crate is only roughly half the size of the other crates and therefore has to be rotated for palletising. “This is where, in the old plant, staff were needed to help make sure that the crates did not jam. The new plant takes care of this smoothly and automatically“, Drißl is delighted to say.

In terms of the pallets used, both brewery pallets and Euro pallets can be loaded and unloaded, as required. In the new plant, these can be fed in via the reject pallet magazine at any time “at the touch of a button” and are then ready for palletising. Drißl explains the advantage of this feature: “We don’t have to changeover pallets in the palletising station in order to process a small batch of around 30 Euro pallets. This not only saves us from having to manually stack the full goods, it also saves a changeover time of at least 45 minutes.“ The plant is, however, also already designed to predominantly process Euro pallets, if the market so requires. In this case, the brewery pallets are fed in via the pallet magazine.

A reduced column height also means that the palletiser can be transported upright. This significantly reduces transport, installation and assembly work.

A reduced column height also means that the palletiser can be transported upright. This significantly reduces transport, installation and assembly work.

“Everything agreed has been completely fulfilled“

In a nutshell: The new palletising station of the Wittmann brewery reliably provides the required performance, despite the challenging spatial conditions. The problems with the turning station no longer exist, the pallet inspection offers enhanced safety and the Euro pallets can now be fed in fully automatically during the operation. Brewmaster Drißl is happy to confirm that following the practical experience gathered with the plant: “Everything agreed has been completely fulfilled. We are absolutely satisfied. The palletising station will certainly not discourage possible follow-up projects.“

Act in advance instead of reacting later

How the consistent use of digital tools creates added value

Predictions are generally very difficult because they are about the future. But one thing is certain: after steam, electricity and automation, digitalisation is set to revolutionise entrepreneurial activity once again, with "digital twin", "virtual commissioning", "AI" and "cloud-based management" being key tools in this regard. These tools are addressed in the following article from a practice-oriented perspective.

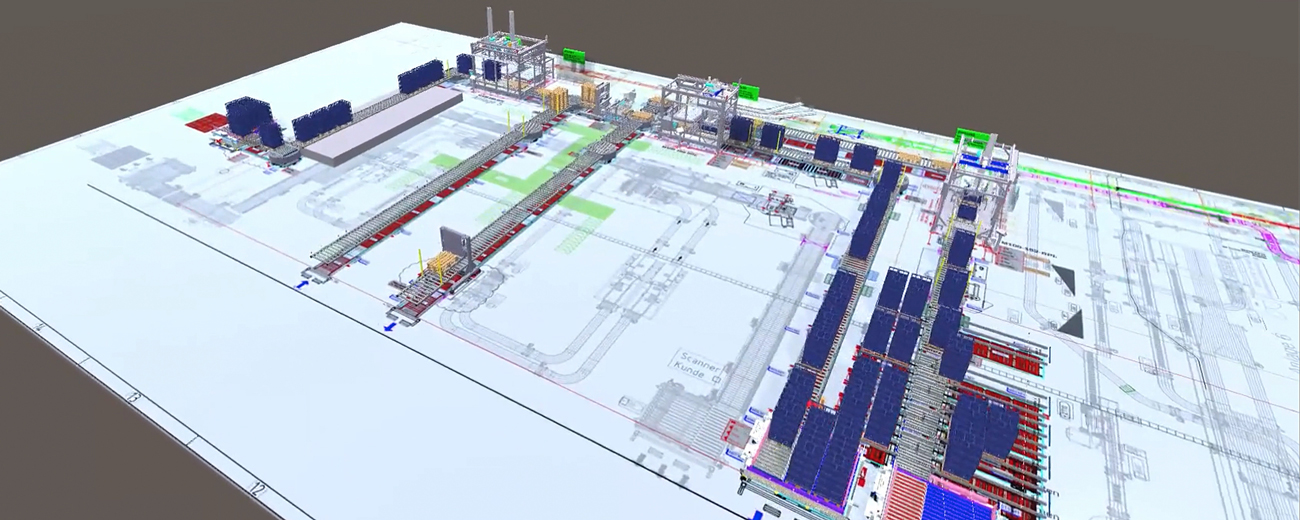

Digital twin

A "digital twin" is a simplified virtual simulation of a machine or plant. The twin is reduced to the essential features that are required for "virtual commissioning". For this purpose, the basic physical behaviour of a machine or plant has to be depicted so that the function of its software can be tested.

“Virtual commissioning" therefore means first and foremost: software testing and analysis using a digital twin. This tool is primarily used for a designed but not yet physically existing machine or plant as well as for a delivered machine or plant.

But what does this actually mean in reality, where is the added value for the customer and the machine manufacturer? This is where it is worth taking a look at the conventional engineering process. This starts with the mechanical design, followed by the software development, in-house and external commissioning as well as the updating of the software modules. This path is taken on a step-by-step basis; there is no provision for parallel work. If upstream problems occur, these have to be eliminated downstream under ever-increasing time pressure - i.e. workload. This is the only way the agreed schedule can be met.

“Virtual commissioning“ parallel to the design

“Virtual commissioning", on the other hand, takes place in the design department, well before the machine is delivered. Ideally, it takes place at the same time as the mechanical and electrical design. Here, for instance, "virtual commissioning" is able to reveal whether an additional sensor is required – and before the machine's design documents are passed on to the next departments. This is an immense advantage, because according to the rule of ten, subsequent changes cause excessive effort and costs. According to this rule, a fault that is only found and corrected during factory commissioning is ten times more expensive than if the correction is made in the software design phase during virtual commissioning.

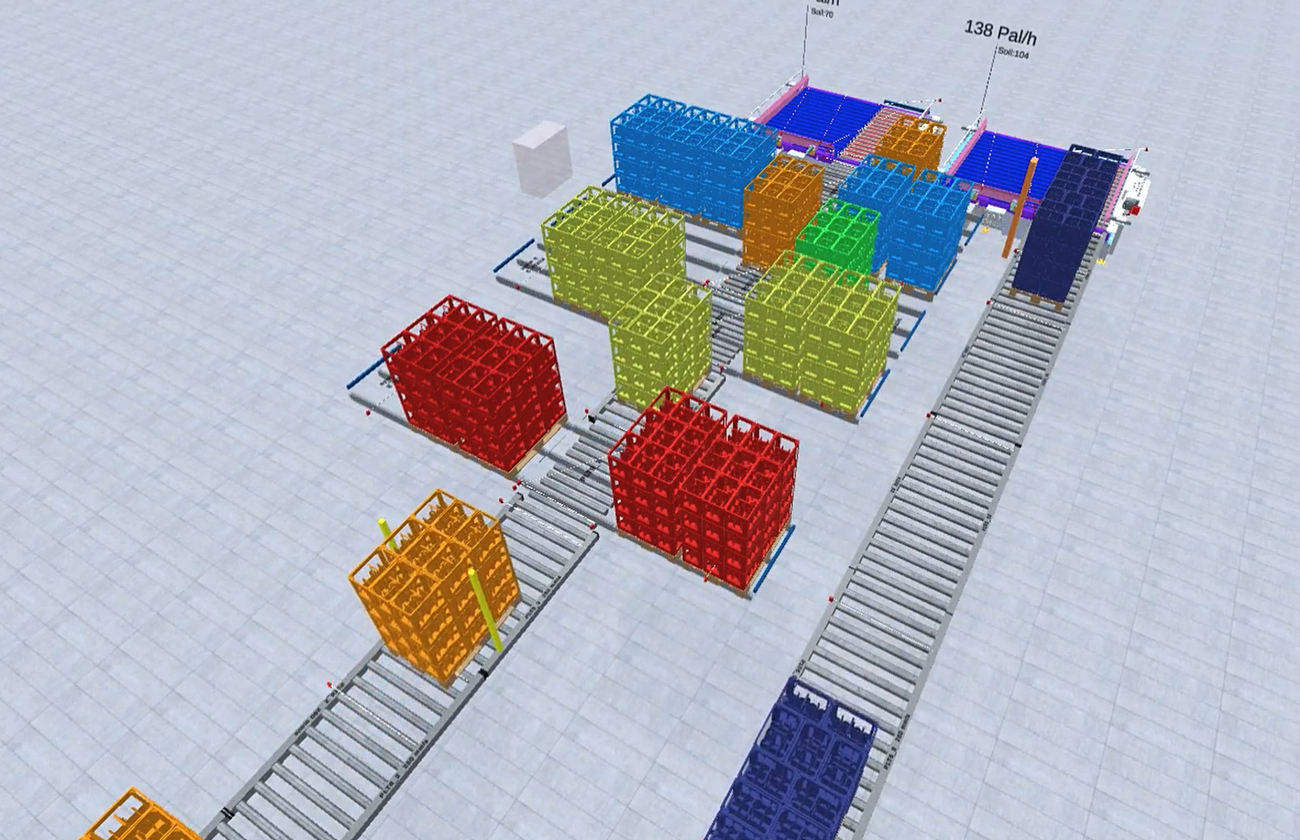

With virtual commissioning, the interaction between conveyor system and machines can be observed and optimised in advance at plant level.

With virtual commissioning, the interaction between conveyor system and machines can be observed and optimised in advance at plant level.

Computer sets the PLC concrete tasks and challenges

The “virtual commissioning“ also gives an answer to the key question: Will the machine be controlled by the real PLC according to the actual situation? A major part of the test, in addition to the normal operation, is the reaction to possible malfunctions. The actual PLC of the machine is set specific tasks and challenges by a simulated model. For instance, the virtual model sends sensor signals to the PLC, which then runs the corresponding program sequences and triggers the actuators in the virtual model, such as the electric drives. The designer thus sees immediately whether the machine and control sequences interact with each other. Or whether, in the event of a simulated sensor fault, all error messages are programmed in such a way that the operator understands what is happening.

In a nutshell: The result of the simulation is a true win-win situation. For the customer, the downtime from the dismantling of the old plant to the restart of production is kept as short as possible. In turn, the machine manufacturer can use its capacities flexibly and therefore more effectively because the employees are not tied to the serial production of a machine. They can work in flexible time slots and independent of the finished physical machine – this being in complete contrast to the previous situation where the fully assembled machine is in the production hall.

Virtual training and predictive maintenance as additional future goals

But that is by no means all: one idea is to also carry out training sessions via "virtual commissioning". The operator should know what he has to do and when to do it during commissioning. A further project concerns the collection of machine data at the customer's premises. The aim here is to create a kind of 24/7 ECG of the machine. The data are recorded in real time and stored in the machine. In the event of a remote service, the machine manufacturer can access the data and, among other things, evaluate them in graphic form or run the data as a simulation on the virtual model. In this way, it is possible to understand why the machine had a fault. This can be important if the customer can only vaguely describe a fault due to the fact that the fault could not be observed. The determined solution is then fed to the plant via remote maintenance. As a consequence, there are no travel expenses and no physical work required at the customer's premises.

This "tracking" also makes it possible to identify when a motor or shaft becomes sluggish, i.e. if the drive requires more electric power. Keyword: predictive maintenance. This is where an independent tool is envisaged that monitors and compares the readings and triggers a service request if the values deviate. It is a well-known fact that it is much better to act in advance than to react in an emergency.

AI mapped machine signals

Another research project in which the EOL Group is involved concerns the development of software that maps machine signals fully automatically using artificial intelligence. To explain this: the PLC delivers a sensor signal, such as operating hours, for example, which must then be correctly classified in the higher-level systems. This classification is currently still done manually, there is no other alternative. The amount of work that artificial intelligence can save is therefore substantial.

But back to the present, to the actual handling of a project on the construction site at the customer's premises. This is where classic project management works through defined project milestones one after the other until the job is successfully completed - in other words, as in classic engineering, in series instead of parallel.

Bottlenecks in complex sorting lines are identified and eliminated in advance.

Bottlenecks in complex sorting lines are identified and eliminated in advance.

Modern project management uses a virtual information and communication platform

Postmodern project management, on the other hand, involves team-oriented work on a virtual information and communication platform. This digital platform maps the project status during the construction site phase, from the delivery through to commissioning, with the greatest possible transparency. Among other things, it graphically displays how many items are currently open, being processed or completed. Information can also be generated quickly and specifically using a filter function. It is also possible to use a digital material list that acts as a push client.

The cloud is also an open communication and documentation platform. Each project partner can, for example, upload photos or videos, propose next steps or prioritise individual items. This makes sure that the status of all project modules is always up to date and clearly understandable. Interactions on the further course of the project are thus immediately visible. This reduces friction and coordination losses and leads to a high level of planning reliability. This solution results firstly in a maximum level of information for all involved employees, customers and suppliers. Secondly, relevant data can now be found automatically, doing away with time-consuming searches. Thirdly, all parties involved in the project gain measureable added value in terms of effort and quality. And this is no mere prediction for the future, as mentioned in the introduction, but based on practical experience gained from many successful projects worldwide using EOL’s own developments “digital twin”, “virtual commissioning” and “LOP 4.0”.

A premiere for KEGs

A portrait of the new keg palletising system at Cölner Hofbräu P. Josef Früh KG

In 2021, Cölner Hofbräu P. Josef Früh KG significantly increased its production capacity and output. This meant that the hourly output of keg palletising had to be doubled – and maintaining the same footprint as the old plant. This challenge was solved using a plant prototype with the proven portal-type machines. This makes the keg palletising system very compact, highly flexible and particularly suitable for the output range in excess of 100 kegs per hour.

Cölner Hofbräu P. Josef Früh KG, or Früh for short, was founded in 1904 by Peter Josef Früh, just a stone’s throw from Cologne’s Cathedral.

In total, six different types of barrels and two types of pallets can be processed with the new system.

In total, six different types of barrels and two types of pallets can be processed with the new system.

In terms of annual production, the third-largest Kölsch brewery

In terms of annual production, Früh is now the third-largest Kölsch brewery with an output of 400,000 hectolitres. Beer has not been brewed at the headquarters since 1987, rather at brewing facilities in Köln-Feldkassel. The former area of the brewery and the residential premises of the Früh family are now used as a hospitality business. Alexander Rolff and Philipp C. Müller now head the Kölsch dynasty in the fifth generation.

The core product of the brewery is Früh-Kölsch, which comes in bottles, cans and various keg sizes. The product range is complemented by non-alcoholic Früh-Kölsch, Früh NaturRadler (shandy) and Früh Sport Fassbrause lemonade.

With 180 kegs/h simply not powerful enough

For Früh, however, this expansion of the beer business meant that the existing palletising and depalletising system for kegs had to be replaced. At 180 kegs/h it was simply not powerful enough, also it could not be expanded adequately. With the expansion investment that was required Früh pursued three clearly defined goals, Bodo Böttcher, technical manager, recalls: “First of all, we needed double the output capacity while maintaining the same footprint. As a second requirement, the new line was to be operated by the same staff team. And thirdly we wanted further functionalities such as an automatic alignment station for incoming empties that would reduce disruptions, an automatic infeed of other pallet formats as well as NVE/SSCC marking and transport security.“

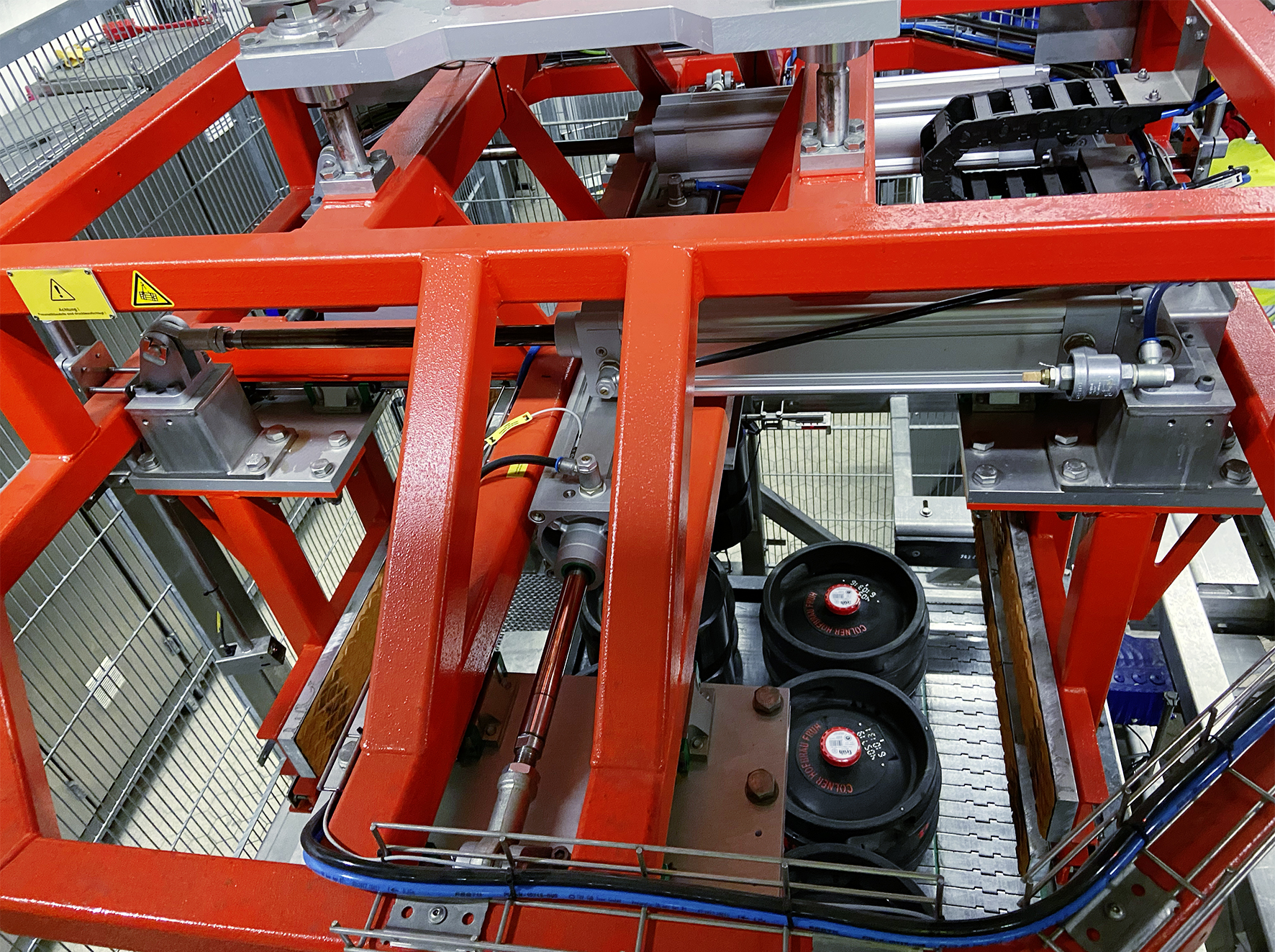

The depalletiser unloads the pallets with the layer pattern specified in the respective production mode

The depalletiser unloads the pallets with the layer pattern specified in the respective production mode

After carefully studying the solutions available on the market, Früh decided in favour of a prototype that used portal-type robots, i.e. a plant that was specifically designed for this type of application for the first time. There were good reasons for this, Böttcher emphasises: “On the one hand, we were convinced straight away by the robust engineering. The supplier had also been given a very positive rating by our professional colleagues. And last but not least, the prototype was the only way to implement the required overall package in the limited amount of space available.“ And for Früh, any structural changes to the buildings were out of the question.

The entire pallet handling is also carried out fully automatically

The entire pallet handling is also carried out fully automatically

Turnkey implementation in the tightest of spaces

The installation involved a 3-axis portal-type Unipal 106 EPL with integrated pallet handling for depalletising, a 2-axis portal-type Unipal 105 BPL for palletising, a Unicontrol pallet inspection system and a pallet conveyor Unitrans P with inline centering. This aligns the stacks of kegs or pallets if they have slipped during transport. This alignment is necessary to ensure a fault-free process and also the required high performance of the palletising system. The company Strapex/Signode was included in the project as OEM for the securing of the loaded pallets. The entire plant was implemented as a general contractor turnkey job. The dismantling of the old system was also included in the contract.

“In this way, a maintenance and operator-friendly plant with extremely reliable machine technology was installed in the tightest of spaces“, Böttcher sums up. Via a double feed station the pallets are conveyed to a centering system which aligns the pallet load to the Euro pallet format. From here the pallet is conveyed directly to the unloader which unloads the kegs onto a massive layer table. The pallet and the intermediate pad pallets are then stacked on a separate pallet stream. The kegs are separated and transferred to the existing conveyor system. The empty pallet is conveyed to the pallet check where it is inspected. If the inspection is not successful, the pallet is conveyed - also via a separate conveyor - to the “Not OK” pallet magazine which can, if required, be automatically converted and used as an “export pallet magazine” for the corresponding product.

After a successful inspection, the empty pallets are transported to the loader. This loads the pallets in up to two layers, depending on the production mode. The loaded pallet is then secured by a horizontal strapper and a vertical strapper using plastic cords. After securing of the pallet the pallet enters a stacking device which places the pallets on top of each other, depending on the production mode. From here the pallets, which are now ready for shipping, are conveyed to the double output from where they are picked up by the forklift operator. With regard to automation, the KEG dry part is designed as a stand-alone solution with signal exchange with the filling. A total of six different keg types and two pallet types can be processed.

: Only the static and dynamic design of the machine technology was adapted to the higher masses to be processed. In addition, a gripper head was developed for the new conditions such as weight and pack variety

: Only the static and dynamic design of the machine technology was adapted to the higher masses to be processed. In addition, a gripper head was developed for the new conditions such as weight and pack variety

„Superb operation from the very first day“

“As the first implemented KEG line ever, the solution ran perfectly from day one. The concept with the well-proven portal-type system worked excellently”, Böttcher recalls. Which is not really surprising, as the system engineering operates in the same way as with beverage crates. Merely the static and dynamic design required adjustment to the larger masses. In addition, a gripper head was developed to cope with the new conditions such as weight and pack variety.

“Particularly the reduced amount of conversion work required for pack changeovers as well as the new functions mean a significant reduction in work and time”, Böttcher is delighted to add. For instance, when changing from 15 l kegs to 50 l kegs the different keg height is adjusted via the programme preselection. The fine adjustment is then carried out by the palletiser with its sensor system. To perform the changeover the operator merely has to adjust a light barrier at the unloader and two position holders on the loader to enable the exact clamping of the new layer pattern.

Problem Covid-19: if there is no demand, there is no palletising

The installation and commissioning under the sudden Covid-19 conditions was a huge challenge. Not only with regard to the extensive hygiene measures. Böttcher goes on to explain: “Just when we were about to start commissioning, the demand for draft beer stagnated due to the Covid restrictions. And no demand means no filling and also no palletising. The actual implementation, including the final acceptance was therefore delayed through no one's fault.”

Performance beyond reproach

Despite the Covid pandemic, the performance was excellent. And it remains so to this day, Böttcher concludes: “Both the plant and the cooperation met our expectations and the work was carried out to our fullest satisfaction. Also the subsequent order for another plant says it all, I think.“

In this way, the KEG palletiser is very compact, highly flexible and particularly suitable for the output range above 100 barrels per hour

In this way, the KEG palletiser is very compact, highly flexible and particularly suitable for the output range above 100 barrels per hour

Kölsch – the history of a beer specialty - source: frueh.de

The first brewer from Cologne to be mentioned in writing was Henricus Medebruwer (“mead brewer”) from Bechergasse in 1285. It was not until over 100 years later, in 1396, that the Cologne brewers’ guild was founded (Zunft der Kölner Brauer). However, they did not brew Kölsch as we know it today. At that time, instead of using hops, beer was brewed with gruit (a mixture of various herbs) and underwent “wild fermentation”. The people of Cologne seemed to like it – and in 1392, for instance, 32,000 hectolitres of gruit beer were already being brewed.

It was not until the beginning of the 15th century that hops were introduced into Cologne’s beer and sold to the people of Cologne as Keutebier. This was the starting shot for a remarkable success story: today, the top-fermented light, yeasty beer is considered a regional specialty and is only allowed to be made in Cologne and the surrounding area, and only served in the so-called Stange glass.

Twice the output, same footprint

A portrait of the new packing and palletising solution for party kegs from Krombacher Brewery.

The Krombacher Brewery, first mentioned in a document in 1803 and family owned for generations, is now Germany’s largest private brewery and one of the most modern in Europe. Its flagship, Krombacher Pils, was once again Germany’s favourite beer last year. In addition, the company Krombacher has built up a successful family of brands. Besides the popular products Krombacher Radler (shandy), Krombacher Alkoholfrei (alcohol-free) and Krombacher Weizen (wheat beer), further successful products have become established in the beverage market over recent years, these being Krombacher’s Fassbrause, Krombacher 0.0%, Krombacher Limobier and Krombacher Brautradition.

These are complemented by non-alcoholic soft drinks which include some very well-known brands. Milestones on this path “from brewery to beverage supplier“ were the acquisitions of brand rights of Schweppes, Orangina and Dr Pepper. Together with these brands the company entered the non-alcoholic soft drinks sector in 2006. The traditional brand Vitamalz followed in 2016. With effect from August 1, 2022 the Krombacher Group has also taken over Heil- und Mineralquellen Germete GmbH, based in Warburg.

„It was really a matter of centimetres." Due to the cramped spatial conditions, Krombacher decided to install a column loader...

„It was really a matter of centimetres." Due to the cramped spatial conditions, Krombacher decided to install a column loader...

The impact of Covid-19 has been manageable

The second financial year in the Covid pandemic has also had an impact on the Krombacher Group, but on a relatively manageable scale when compared with the sector as a whole: a total output of 7.335 million hectolitres was achieved across all brands – this representing a drop of 0.9 percent. The parent brand Krombacher suffered a year-on-year loss of 2.3 percent, ending up with an output of 5.590 million hectolitres. The performance of the non-alcoholic soft drink family was again very encouraging. Output increased by around five percent to 1.453 million hectolitres. A key driver here was once again the Zero variants. The share of non-alcoholic products in the Krombacher Group’s total output thus rose to around 38 percent in 2021. “Especially in these difficult times, it has become evident that our strategy of consistent diversification of the product and packaging spectrum enables us to meet the diverse wishes and needs of the market in the best possible way“, comments Uwe Riehs, chief marketing officer, on the annual results.

Clearly in a better position with a wrap-around solution

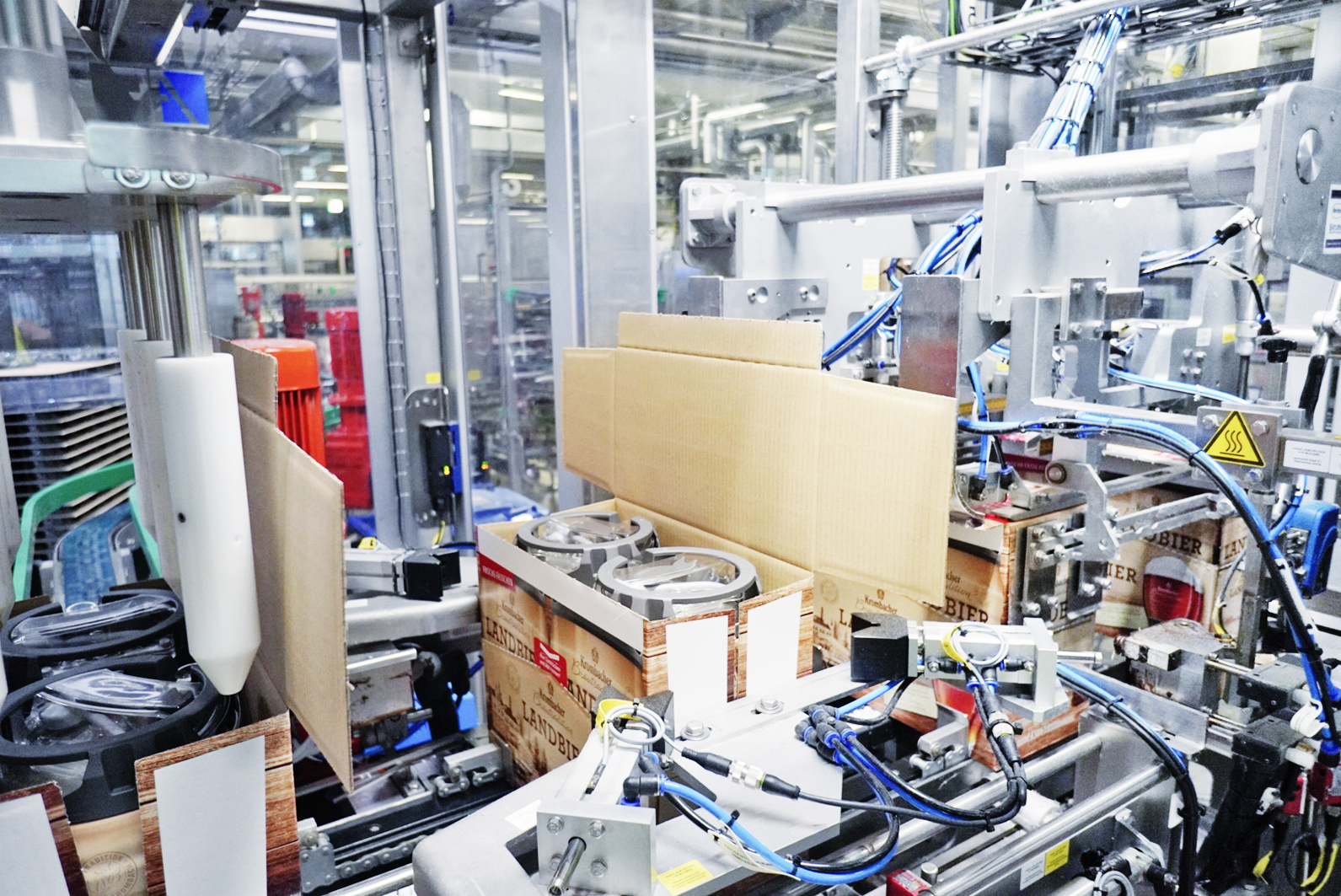

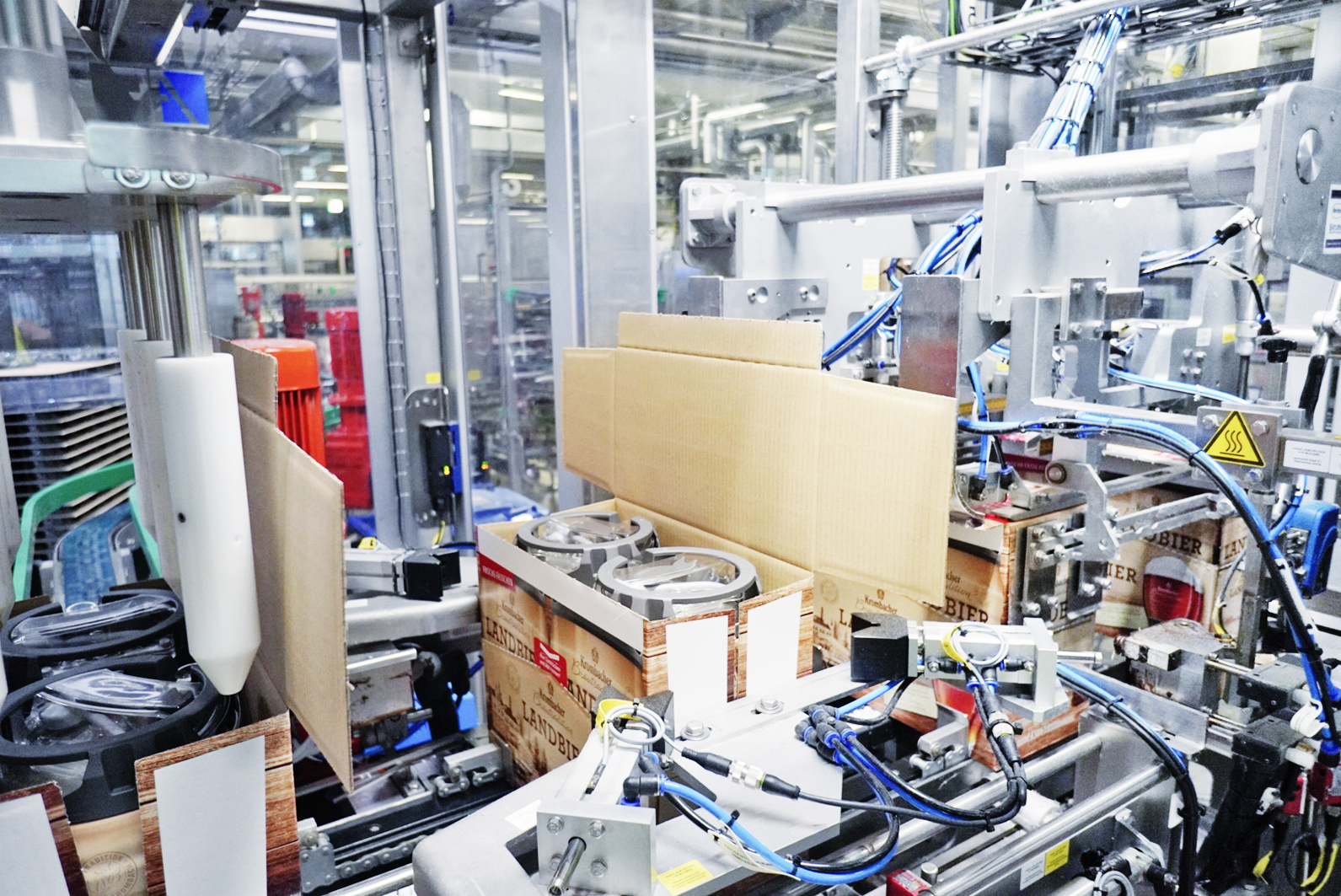

In the packaging area, Krombacher successfully completed a further investment in a smaller but nevertheless significant segment at the beginning of 2022. A segment that certainly gained popularity during the Covid pandemic and the related shutdown of the hospitality sector is the 5-litre party keg - for serving draught beer at home. Here Krombacher distinguishes between the party keg for “Bavarian-type” keg tapping and the fresh keg, which also has an integrated CO2 dispensing unit.

...in combination with a wrap-around packer.

...in combination with a wrap-around packer.

“We had an existing plant for both versions - this was a pick-and-place solution comprising a packer, loader and stretcher”, recalls Rainer Bub, operations engineering/project manager at Krombacher. However, the older machines were getting on in years. They were therefore requiring a lot of maintenance, spare parts were becoming difficult to acquire and the machines were susceptible to faults, leading to a decline in the overall efficiency of the filling system. Oliver Mette, head of the plant development department goes on to explain: “The old plant was therefore practically running around the clock, seven days a week, in order to cope with the demand.“ It was also becoming increasingly difficult to meet the rising requirements in connection with occupational safety on the machine side. All of this combined led to Krombacher looking for a new solution. The question was: What is technically feasible in the available space?” And this space was equal to that of the old plant - there was no scope whatsoever. “This is where we were clearly better off with a wrap-around solution than with a set packer. It was literally a matter of centimetres,” says Bub.

The new line is designed for a maximum output of 1,320 cans equal to 660 wrap-arounds per hour.

The new line is designed for a maximum output of 1,320 cans equal to 660 wrap-arounds per hour.

Mette explains further: “In the old cases the top and bottom sides were sealed with adhesive tape. We can now do without this tape completely because the new wrap-around packaging is glued using hot melt glue. We can also influence the stability of the packaging through the design of the glue dots.“ An important aspect, considering the packs contain two kegs each and weigh over ten kilogrammes. A positive additional effect is that the new packaging can be opened via the perforation without requiring the use of any tool.

Compact combination unit comprising packer, loader and stretcher

Krombacher decided in favour of installing a loader of the type Unipal 108, with low-floor pallet conveyor, in combination with an A+F ModuLine for the wrap-around processing of two formats. For one simple reason: “No other machine manufacturer was able to offer us a combination unit of packer, loader and stretcher of this quality for the given space“, Bub concludes. In addition, according to Mette, there was the much simpler interface clarification: “We had just one contact partner for the overall solution.” The scope of the contract also included the conveyor line required for the connection to the keg filler, the control as well as the integration of the pallet securing. The overall package, comprising keg packing and palletising, was completed on a turnkey basis.

The new plant is designed for a maximum output of 1,320 party kegs that is 660 wrap-arounds per hour. As a comparison: the old plant had an output of 600 party kegs per hour at best. In a nutshell, the challenge was to at least double the hourly output on the same site – while of course complying with the latest ergonomic and occupational specifications. “This output is not currently called for because at 620 kegs per hour we are running at roughly the maximum output of the filler. But we are equipped and ready for future growth”, Mette explains.

A 90° selective turning station integrated in the infeed of the loader aligns the wrap-arounds into a row according to the desired layer pattern.

A 90° selective turning station integrated in the infeed of the loader aligns the wrap-arounds into a row according to the desired layer pattern.

Layer formation directly in the loader head

The frequently mentioned, extremely tight space conditions were particularly challenging. For this reason, also the loader of column-type design and the low-floor pallet conveyor with a height of just over ten centimetres were chosen. Another important factor regarding optimal use of the available space was the 90° selective turning station of A+F. This makes it possible to omit the normally installed layer table, meaning a decisive gain in compactness. In this way, the customer was able to gain major advantages, such as amply dimensioned working areas and excellent accessibility.

This turning station, integrated in the infeed of the loader, aligns the wrap-arounds in a row according to the desired layer pattern. The respective row is then fed to the loader head via a row pusher until the layer pattern has been formed completely. The actual layer formation thus takes place directly in the roller griper head. The completed layers are then placed on the pallet until the pallet has a total of 60 cases, or 120 party kegs. In the case of export pallets there are actually 72 cases. The operation of the newly developed universal roller gripper head is particularly gentle on the product. This gripper head also takes over the pallet and layer pad handling. The loaded pallet is then secured using a stretch wrapper and transported away.

“An excellent example of what can be achieved thanks to the synergies that have been created“

To solve this intricate task a great deal of customisation was therefore needed based on the proven machine technology of two sister companies. “This is an excellent example of what can be achieved thanks to the synergies that have been created. Neither of the two companies could have accomplished this unprecedented feat on their own“, Bub points out. The plant has been running since the end of the first quarter of 2022. Between the dismantling stage and the commissioning there was a period of just ten days. “An important aspect,” says Metter, “was that the commissioning engineer was able to cover both the mechanics and automation here at our construction site.“ The commissioning was followed up with support in the production over fourteen days. “We went straight into three-shift operation during this period. BMS and A+F accompanied this phase in two shifts and we were thus able to reach full performance quickly,” says Bub.

By means of a row pusher, the respective row is fed into the loading head until the layer pattern is completely formed. This means that there is no need for a layer table, which is a decisive plus in terms of compactness.

By means of a row pusher, the respective row is fed into the loading head until the layer pattern is completely formed. This means that there is no need for a layer table, which is a decisive plus in terms of compactness.

And does the experience gathered in practice meet the expectations placed in the investment? Bub sums up: “We have accomplished the set goal of significantly reducing susceptibility clearly achieved.“ As a result of this, the overall efficiency of the filling line has been increased as planned. The operating personnel are the same as with the old plant. It was also never the aim to save on personnel, Mette emphasises: “It was all about state-of-the-art instead of old, reliability instead of susceptibility to faults, and ideally that we would not have to go 24/7.“ Krombacher also found the constructive and flexible cooperation very positive. “As customers, we were helped quickly and without red tape, despite the fact that there were still some spontaneous requests for changes,“ Bub recalls. Mette goes on to conclude: “A big praise to the whole project team. We were and are once again very satisfied.”

Twice the output, same footprint

A portrait of the new packing and palletising solution for party kegs from Krombacher Brewery.

The Krombacher Brewery, first mentioned in a document in 1803 and family owned for generations, is now Germany’s largest private brewery and one of the most modern in Europe. Its flagship, Krombacher Pils, was once again Germany’s favourite beer last year. In addition, the company Krombacher has built up a successful family of brands. Besides the popular products Krombacher Radler (shandy), Krombacher Alkoholfrei (alcohol-free) and Krombacher Weizen (wheat beer), further successful products have become established in the beverage market over recent years, these being Krombacher’s Fassbrause, Krombacher 0.0%, Krombacher Limobier and Krombacher Brautradition.

These are complemented by non-alcoholic soft drinks which include some very well-known brands. Milestones on this path “from brewery to beverage supplier“ were the acquisitions of brand rights of Schweppes, Orangina and Dr Pepper. Together with these brands the company entered the non-alcoholic soft drinks sector in 2006. The traditional brand Vitamalz followed in 2016. With effect from August 1, 2022 the Krombacher Group has also taken over Heil- und Mineralquellen Germete GmbH, based in Warburg.

„It was really a matter of centimetres." Due to the cramped spatial conditions, Krombacher decided to install a column loader...

„It was really a matter of centimetres." Due to the cramped spatial conditions, Krombacher decided to install a column loader...

The impact of Covid-19 has been manageable

The second financial year in the Covid pandemic has also had an impact on the Krombacher Group, but on a relatively manageable scale when compared with the sector as a whole: a total output of 7.335 million hectolitres was achieved across all brands – this representing a drop of 0.9 percent. The parent brand Krombacher suffered a year-on-year loss of 2.3 percent, ending up with an output of 5.590 million hectolitres. The performance of the non-alcoholic soft drink family was again very encouraging. Output increased by around five percent to 1.453 million hectolitres. A key driver here was once again the Zero variants. The share of non-alcoholic products in the Krombacher Group’s total output thus rose to around 38 percent in 2021. “Especially in these difficult times, it has become evident that our strategy of consistent diversification of the product and packaging spectrum enables us to meet the diverse wishes and needs of the market in the best possible way“, comments Uwe Riehs, chief marketing officer, on the annual results.

Clearly in a better position with a wrap-around solution

In the packaging area, Krombacher successfully completed a further investment in a smaller but nevertheless significant segment at the beginning of 2022. A segment that certainly gained popularity during the Covid pandemic and the related shutdown of the hospitality sector is the 5-litre party keg - for serving draught beer at home. Here Krombacher distinguishes between the party keg for “Bavarian-type” keg tapping and the fresh keg, which also has an integrated CO2 dispensing unit.

...in combination with a wrap-around packer.

...in combination with a wrap-around packer.

“We had an existing plant for both versions - this was a pick-and-place solution comprising a packer, loader and stretcher”, recalls Rainer Bub, operations engineering/project manager at Krombacher. However, the older machines were getting on in years. They were therefore requiring a lot of maintenance, spare parts were becoming difficult to acquire and the machines were susceptible to faults, leading to a decline in the overall efficiency of the filling system. Oliver Mette, head of the plant development department goes on to explain: “The old plant was therefore practically running around the clock, seven days a week, in order to cope with the demand.“ It was also becoming increasingly difficult to meet the rising requirements in connection with occupational safety on the machine side. All of this combined led to Krombacher looking for a new solution. The question was: What is technically feasible in the available space?” And this space was equal to that of the old plant - there was no scope whatsoever. “This is where we were clearly better off with a wrap-around solution than with a set packer. It was literally a matter of centimetres,” says Bub.

The new line is designed for a maximum output of 1,320 cans equal to 660 wrap-arounds per hour.

The new line is designed for a maximum output of 1,320 cans equal to 660 wrap-arounds per hour.

Mette explains further: “In the old cases the top and bottom sides were sealed with adhesive tape. We can now do without this tape completely because the new wrap-around packaging is glued using hot melt glue. We can also influence the stability of the packaging through the design of the glue dots.“ An important aspect, considering the packs contain two kegs each and weigh over ten kilogrammes. A positive additional effect is that the new packaging can be opened via the perforation without requiring the use of any tool.

Compact combination unit comprising packer, loader and stretcher

Krombacher decided in favour of installing a loader of the type Unipal 108, with low-floor pallet conveyor, in combination with an A+F ModuLine for the wrap-around processing of two formats. For one simple reason: “No other machine manufacturer was able to offer us a combination unit of packer, loader and stretcher of this quality for the given space“, Bub concludes. In addition, according to Mette, there was the much simpler interface clarification: “We had just one contact partner for the overall solution.” The scope of the contract also included the conveyor line required for the connection to the keg filler, the control as well as the integration of the pallet securing. The overall package, comprising keg packing and palletising, was completed on a turnkey basis.

The new plant is designed for a maximum output of 1,320 party kegs that is 660 wrap-arounds per hour. As a comparison: the old plant had an output of 600 party kegs per hour at best. In a nutshell, the challenge was to at least double the hourly output on the same site – while of course complying with the latest ergonomic and occupational specifications. “This output is not currently called for because at 620 kegs per hour we are running at roughly the maximum output of the filler. But we are equipped and ready for future growth”, Mette explains.

A 90° selective turning station integrated in the infeed of the loader aligns the wrap-arounds into a row according to the desired layer pattern.

A 90° selective turning station integrated in the infeed of the loader aligns the wrap-arounds into a row according to the desired layer pattern.

Layer formation directly in the loader head

The frequently mentioned, extremely tight space conditions were particularly challenging. For this reason, also the loader of column-type design and the low-floor pallet conveyor with a height of just over ten centimetres were chosen. Another important factor regarding optimal use of the available space was the 90° selective turning station of A+F. This makes it possible to omit the normally installed layer table, meaning a decisive gain in compactness. In this way, the customer was able to gain major advantages, such as amply dimensioned working areas and excellent accessibility.

This turning station, integrated in the infeed of the loader, aligns the wrap-arounds in a row according to the desired layer pattern. The respective row is then fed to the loader head via a row pusher until the layer pattern has been formed completely. The actual layer formation thus takes place directly in the roller griper head. The completed layers are then placed on the pallet until the pallet has a total of 60 cases, or 120 party kegs. In the case of export pallets there are actually 72 cases. The operation of the newly developed universal roller gripper head is particularly gentle on the product. This gripper head also takes over the pallet and layer pad handling. The loaded pallet is then secured using a stretch wrapper and transported away.

“An excellent example of what can be achieved thanks to the synergies that have been created“

To solve this intricate task a great deal of customisation was therefore needed based on the proven machine technology of two sister companies. “This is an excellent example of what can be achieved thanks to the synergies that have been created. Neither of the two companies could have accomplished this unprecedented feat on their own“, Bub points out. The plant has been running since the end of the first quarter of 2022. Between the dismantling stage and the commissioning there was a period of just ten days. “An important aspect,” says Metter, “was that the commissioning engineer was able to cover both the mechanics and automation here at our construction site.“ The commissioning was followed up with support in the production over fourteen days. “We went straight into three-shift operation during this period. BMS and A+F accompanied this phase in two shifts and we were thus able to reach full performance quickly,” says Bub.

By means of a row pusher, the respective row is fed into the loading head until the layer pattern is completely formed. This means that there is no need for a layer table, which is a decisive plus in terms of compactness.

By means of a row pusher, the respective row is fed into the loading head until the layer pattern is completely formed. This means that there is no need for a layer table, which is a decisive plus in terms of compactness.

And does the experience gathered in practice meet the expectations placed in the investment? Bub sums up: “We have accomplished the set goal of significantly reducing susceptibility clearly achieved.“ As a result of this, the overall efficiency of the filling line has been increased as planned. The operating personnel are the same as with the old plant. It was also never the aim to save on personnel, Mette emphasises: “It was all about state-of-the-art instead of old, reliability instead of susceptibility to faults, and ideally that we would not have to go 24/7.“ Krombacher also found the constructive and flexible cooperation very positive. “As customers, we were helped quickly and without red tape, despite the fact that there were still some spontaneous requests for changes,“ Bub recalls. Mette goes on to conclude: “A big praise to the whole project team. We were and are once again very satisfied.”

You want to read more? Click here for the printed version.